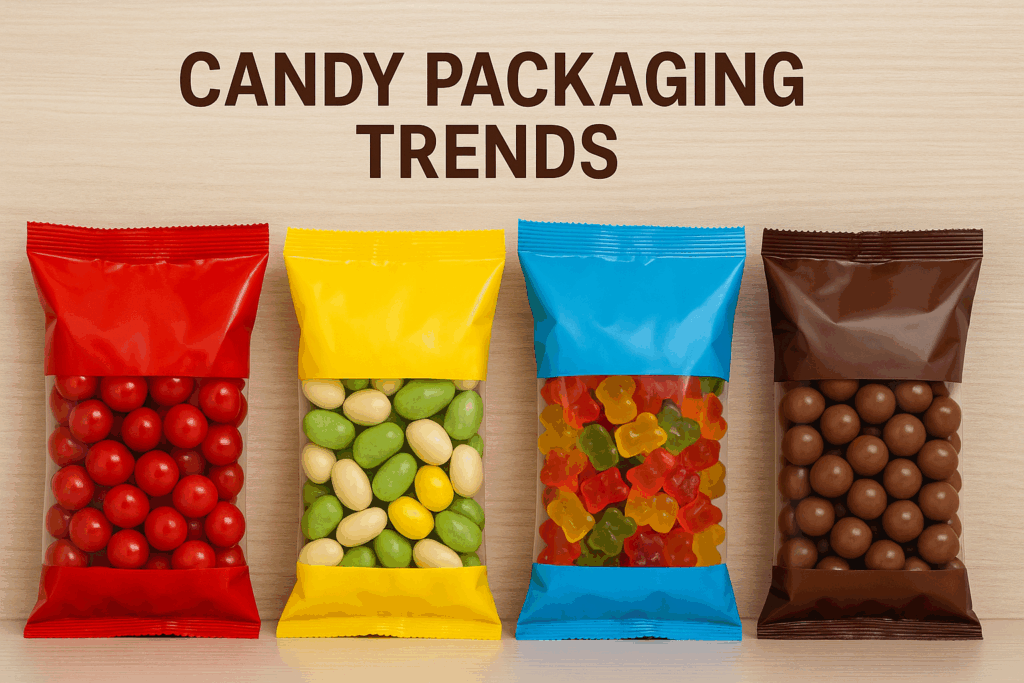

The Future of Candy Packaging: 5 Trends Sweetening the Industry in 2025

Candy packaging is evolving rapidly as brands face rising consumer demands and seasonal production spikes. This blog explores five key trends from sustainability and speed to safety and shelf appeal that will define the future of candy packaging in 2025 and beyond.

The Candy Packaging Machine Built for Today’s Demands and Tomorrow’s Growth

As candy demand grows and seasonal spikes intensify, manufacturers need a packaging solution that can keep pace. This blog explores why the Vertobagger Hornet candy packaging machine is the ideal choice for modern candy producers, combining speed, flexibility, and product protection to meet the industry’s toughest challenges.

Sustainable Candy Packaging: How the Vertobagger Hornet Helps Brands Go Green

Sustainable candy packaging is no longer optional; it’s essential. This blog explores how candy brands can reduce their environmental impact and stay competitive by embracing sustainable materials, smarter processes, and modern packaging machines like the Vertobagger Hornet.

Choosing the Right Food Powder Packaging Machine: Why the Falcon Delivers

Powdered foods are unforgiving; they clump, dust, and demand precision. The Falcon food powder packaging machine is built for these challenges, delivering speed, consistency, and flexibility so brands can scale without waste.

Food Powder Packaging Is Evolving. Why Pillow Bags Are the Format Brands Trust

Powdered foods are growing fast, from coffee and spices to nutrition blends. Packaging is now as critical as formulation and pillow bags are proving to be the format powdered categories trust. This blog explores the market growth, technical challenges, and consumer trends driving pillow bags to the forefront of food powder packaging. Read the blog.

Sustainable Food Powder Packaging: Why the Falcon Makes It Possible

Sustainability in food powder packaging is now a competitive necessity. Learn how the Falcon helps brands transition to eco-friendly films, reduce waste, and maintain airtight seals, all while running at high speed.

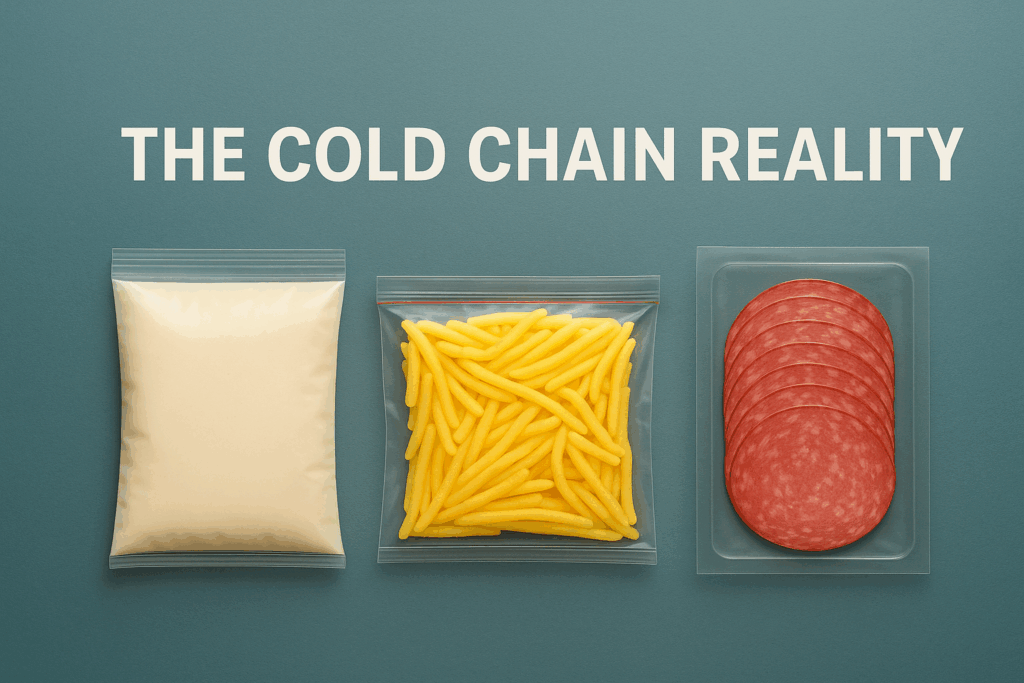

The Cold Chain Reality: Why Meat, Cheese, and Dairy Packaging Needs a Rethink

In dairy, meat, and cheese production, time is never neutral. Every weak seal, every long washdown, and every changeover cuts into margins. This blog explores why dairy packaging and its counterparts in meat and cheese are being rethought under retailer, regulatory, and sustainability pressures, and why flexible, reliable systems are now essential for survival in the cold chain.

Read the blog to learn why dairy packaging is no longer just containment, it’s a strategy.

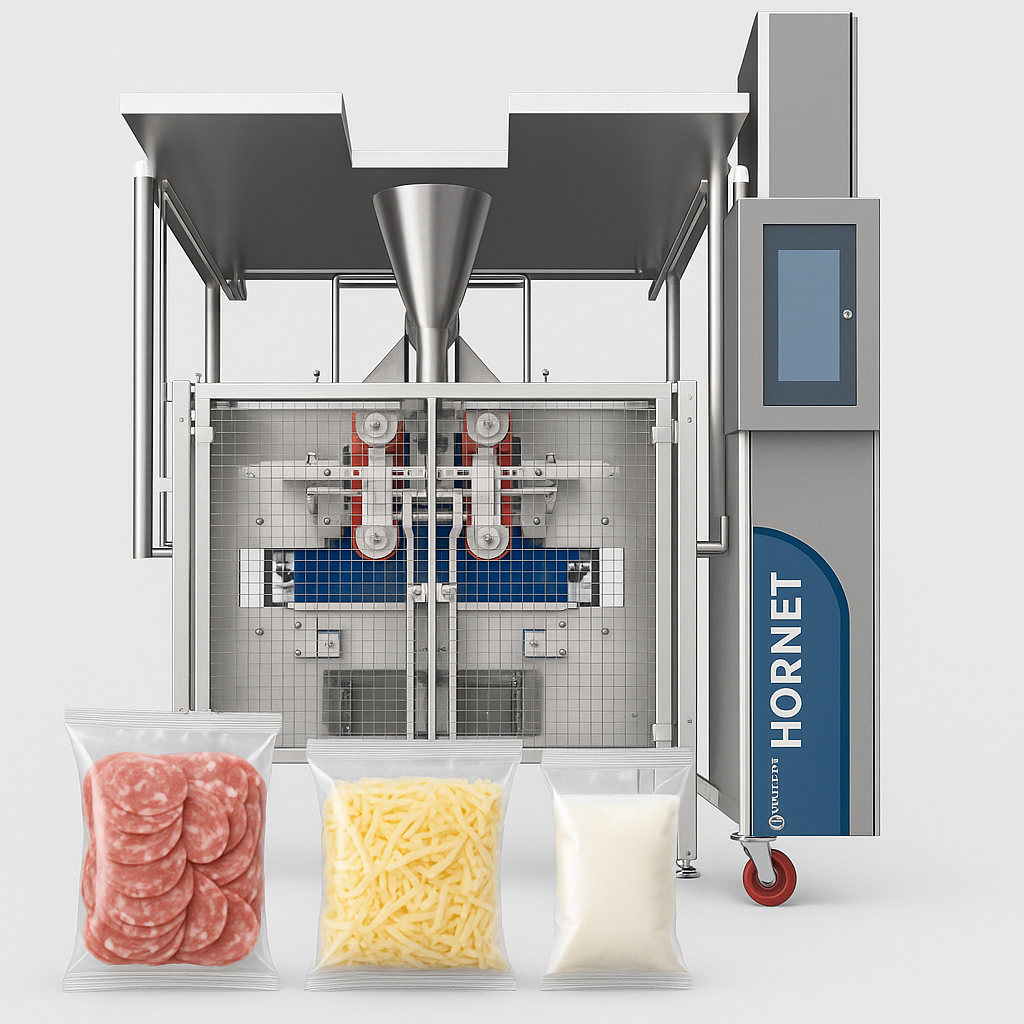

Washdowns Without Waste: Rethinking the Meat, Cheese, & Dairy Packaging Machine for the Cold Chain

Washdowns don’t have to waste hours of production time. In dairy, meat, and cheese packaging, the right machine can mean stronger seals, faster changeovers, and less downtime. Learn how the Hornet Washdown, a rugged, customizable dairy packaging machine is helping producers reclaim uptime, protect shelf life, and stay competitive in the cold chain.

Read the blog to see how smarter packaging machines solve the real challenges dairy, meat, and cheese producers face.

The Sustainability Dilemma Dairy, Meat, and Cheese Producers Can’t Ignore

Sustainable dairy packaging isn’t a future goal; it’s a present-day requirement. This blog explores the challenges of running recyclable films in dairy, meat, and cheese production, why traditional machines fall short, and how the Hornet Washdown enables sustainability without sacrificing freshness, speed, or efficiency. Read the blog.

First-Time Buyer’s Guide: Why Similar-Looking Packaging Machines Perform So Differently

For first-time buyers, packaging machines can be confusing; three models may look nearly identical yet carry price tags that range from $30,000 to $90,000. This guide uncovers why similar-looking machines perform so differently and what to look for before you invest. Read the full blog to make a smarter, more confident buying decision.