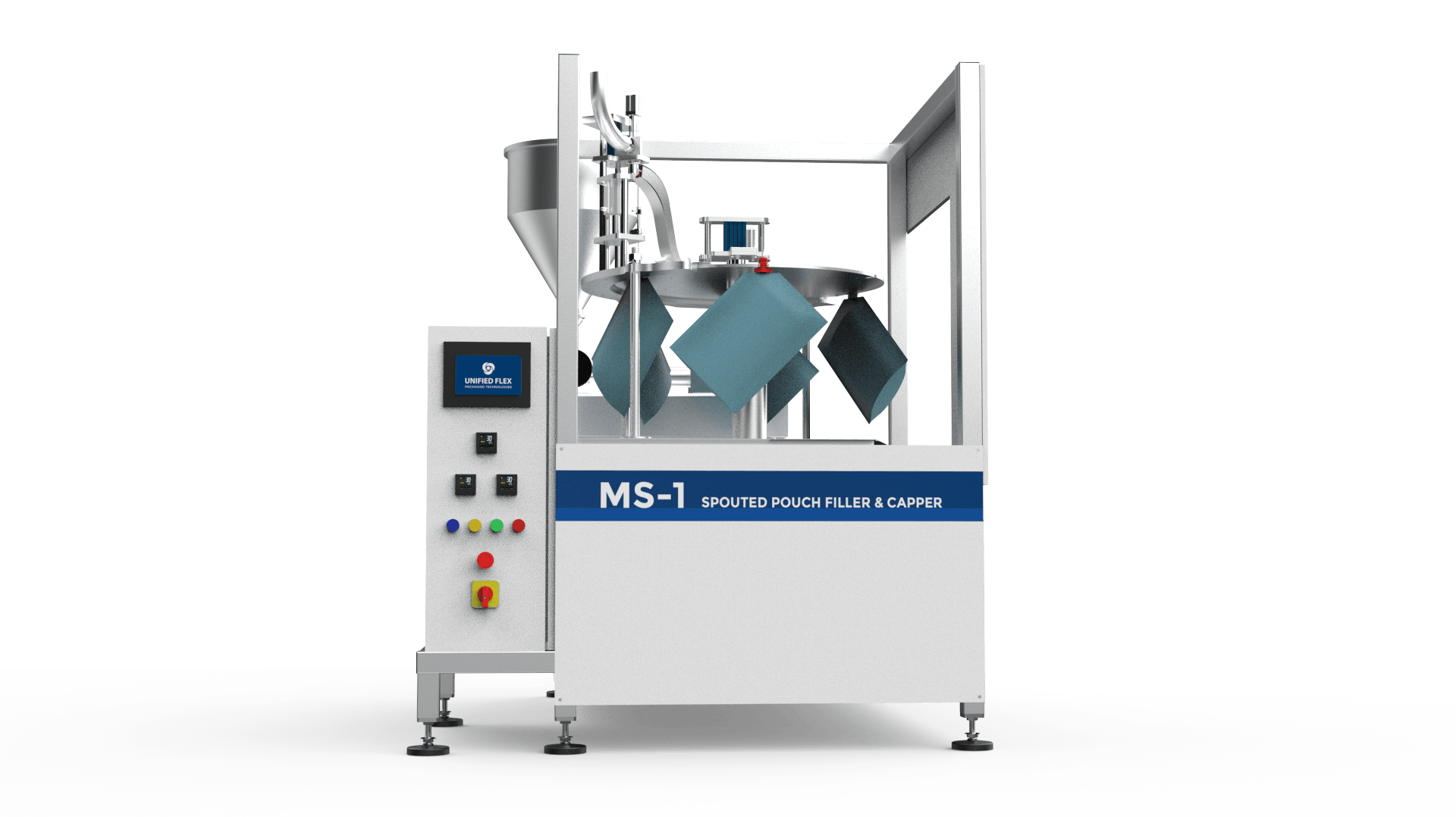

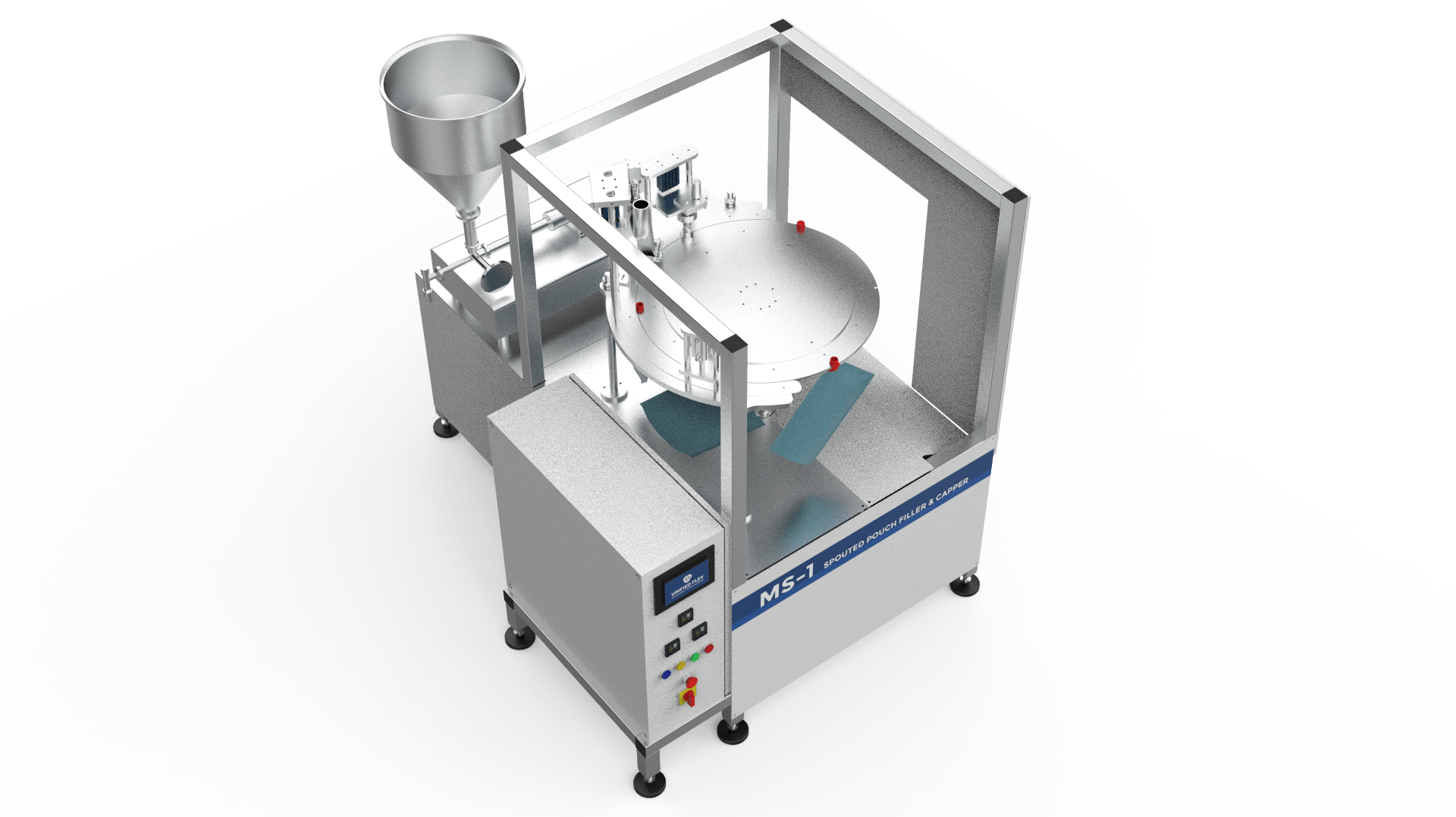

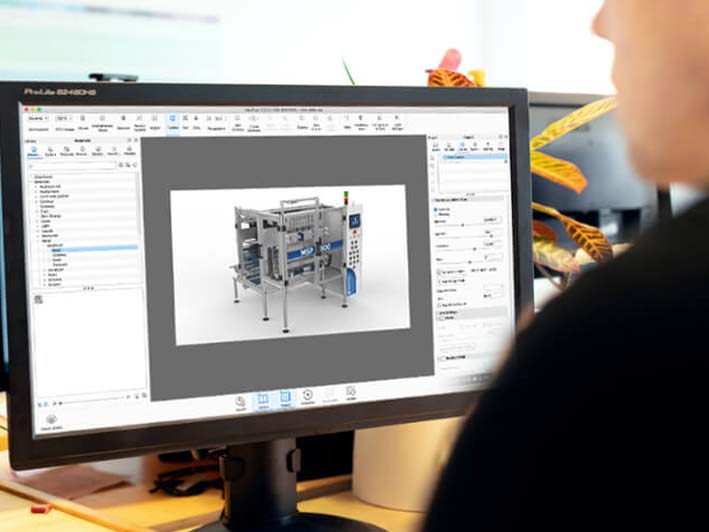

The Spouted Pouch Filler & Capper MS-1 is a versatile vertical form fill seal machine designed for single-pouch processing. It efficiently handles both viscous and free-flowing liquids, including those with particulates. This machine caters to a wide range of applications, from edible oils, dressings, and beverages to non-edible products like paints, soaps, and detergents. Its easy integration with piston fillers or positive displacement pumps makes the Spouted Pouch Filler & Capper MS-1 a reliable and adaptable solution for your liquid packaging needs.

To download the brochure or to receive the floor plans for the Spouted Pouch Filler & Capper MS-1, visit the ‘More Resources’ section below.