VERTICAL FORM FILL SEAL MACHINES

Built Around Your Product — Not the Other Way Around

Unified Flex designs vertical form fill seal (VFFS) machines for applications where process control, repeatability, and long-term reliability are critical. Our systems are engineered for demanding production environments, from powders and liquids to specialty products that require consistent sealing, controlled handling, and dependable uptime.

Instead of a one-size-fits-all platform, each machine is engineered around your product behavior, packaging format, and operating requirements. That application-driven approach provides stable performance across a wide range of products while still supporting customized automation when your line needs it.

Our VFFS platforms are designed with a focus on:

- Repeatable sealing and forming performance

- Robust, serviceable mechanical and control designs

- Practical automation that supports real-world operation

- Long-term support and engineering involvement

Unified Flex VFFS platforms deliver repeatable sealing/forming, robust serviceable mechanical + controls, practical real-world automation, and long-term engineering support.

Designed, built, and supported in North America, our team stays involved from feasibility and configuration through commissioning and ongoing support.

For applications beyond a standard VFFS machine, our configurable platforms are built to adapt to real production demands.

Proven Across Diverse Product Behaviors

Every product brings unique packaging challenges, shaped by flow, viscosity, or particle structure. Unified Flex has delivered solutions across 20+ industries, from food, beverage, and nutraceuticals to pharmaceuticals, pet food, personal care, and industrial applications. This breadth of experience means we’ve solved challenges like yours before, and we know how to engineer packaging systems that deliver consistent, efficient, and reliable performance.

Applications That Speak for Themselves

Viscous or Semi-Viscous Liquids

Perfectly packed popsicles, a testament to our turnkey packaging expertise for viscous products.

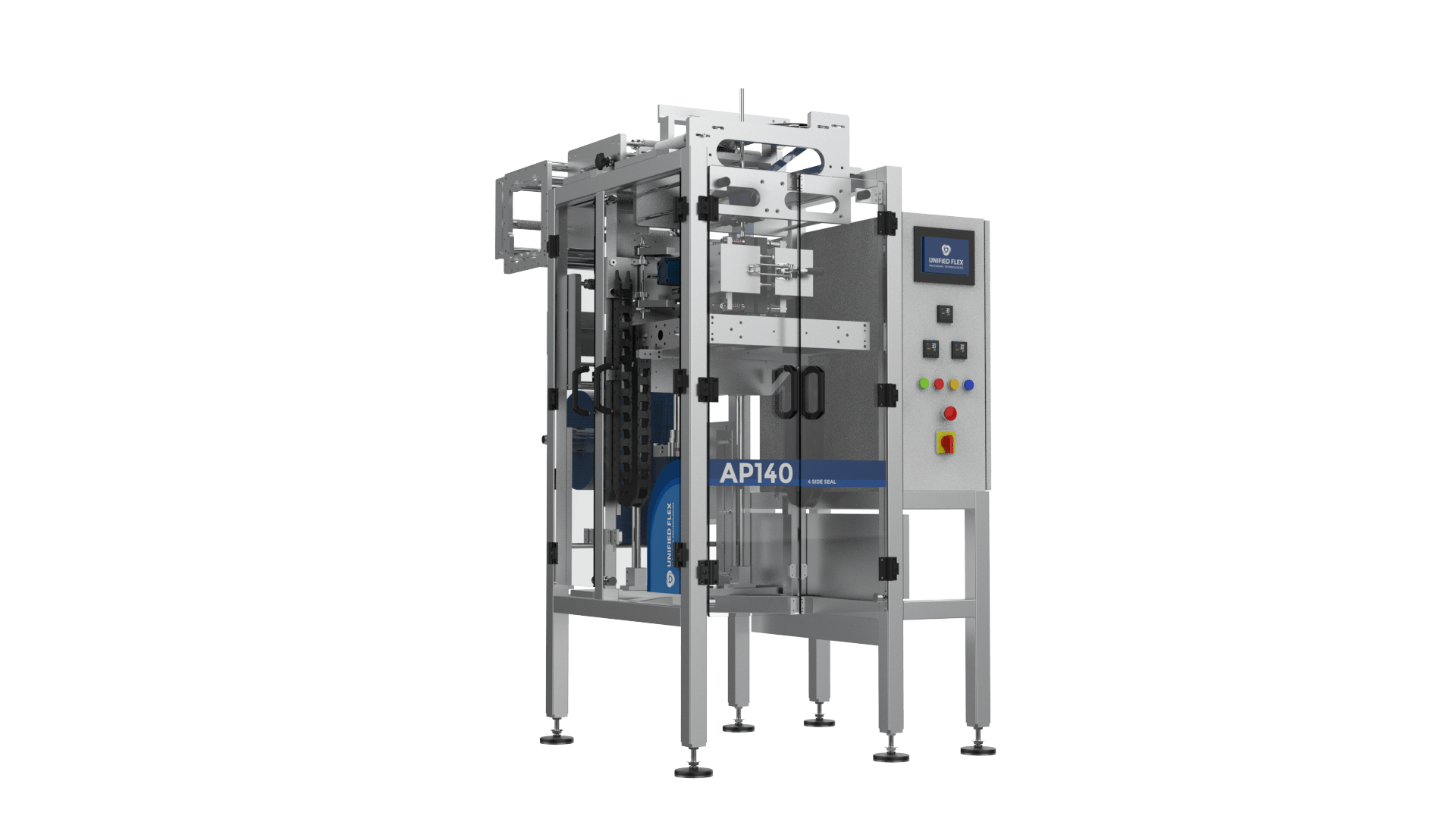

Precision piston filling meets clean, consistent sachet packaging, an AP-140 setup built for efficient output, easy control, and reliable seals across multiple bag styles.

Granular & Powder Products

Consistent feeding and accurate placement, showcasing smart automation in a robust dual conveyor + VFFS setup, built with stainless-steel construction for demanding environments.

Big flexibility in a compact footprint, watch the AP-140 with auger filler run stick packs, 3-side seal, 4-side seal, and pillow bags with smooth, reliable sealing.

Solids

From snacks to powders, the Vertobagger Hornet keeps output steady, servo-driven belts, photo sensor seal control, and up to 80 pouches per minute.

From powders to granules, the AP-180 keeps pouch packaging simple, flexible bag types, consistent performance, and minimal downtime by design.

Packaging Challenges We Solve

Every manufacturer faces recurring hurdles that drain time, waste product, and erode confidence. We address these challenges head-on, turning them into dependable outcomes.

- Frequent changeovers — switching SKUs or bag sizes without losing hours of production.

- Training new operators — intuitive controls and simple setups that shorten the learning curve.

- Downtime risk — keeping uptime high with precise, durable parts that minimize rework.

- Seal integrity — consistent, high-quality seals that prevent leaks, recalls, and unhappy customers.

- Film tracking issues — reliable film handling for clean, straight packages every run.

- Hygiene requirements — washdown-friendly stainless steel designs that reduce contamination risk.

- Maintenance complexity — built-in diagnostics and robust frames for faster troubleshooting and less upkeep.

Our role is simple: remove these frustrations so your operation runs smoothly, safely, and profitably.

Engineered Features, Tangible Benefits.

Every feature on a Unified Flex machine exists to remove complexity and build confidence in your packaging line.

VFFS Machine Features

What it Means For You

Our Process:

Structured, Transparent, Reliable

When you work with Unified Flex, you get more than a machine. You get a process that minimizes risk:

- Understand your product & goals

- Engineer the right design for your plant requirements

- Test every system in-house before shipment

- Factory Acceptance Test (FAT) with your team

- Install, train, and support with North American service & parts

Why Manufacturers Choose Unified Flex

- North American-built machines - Fast access to parts and support.

- Process-driven engineering - Consistency, not improvisation.

- Proven experience across industries - Food, pharma, medical, industrial.

- Focused on reliability - No lofty promises, just dependable results.

- Partnership approach - We align with your long-term goals

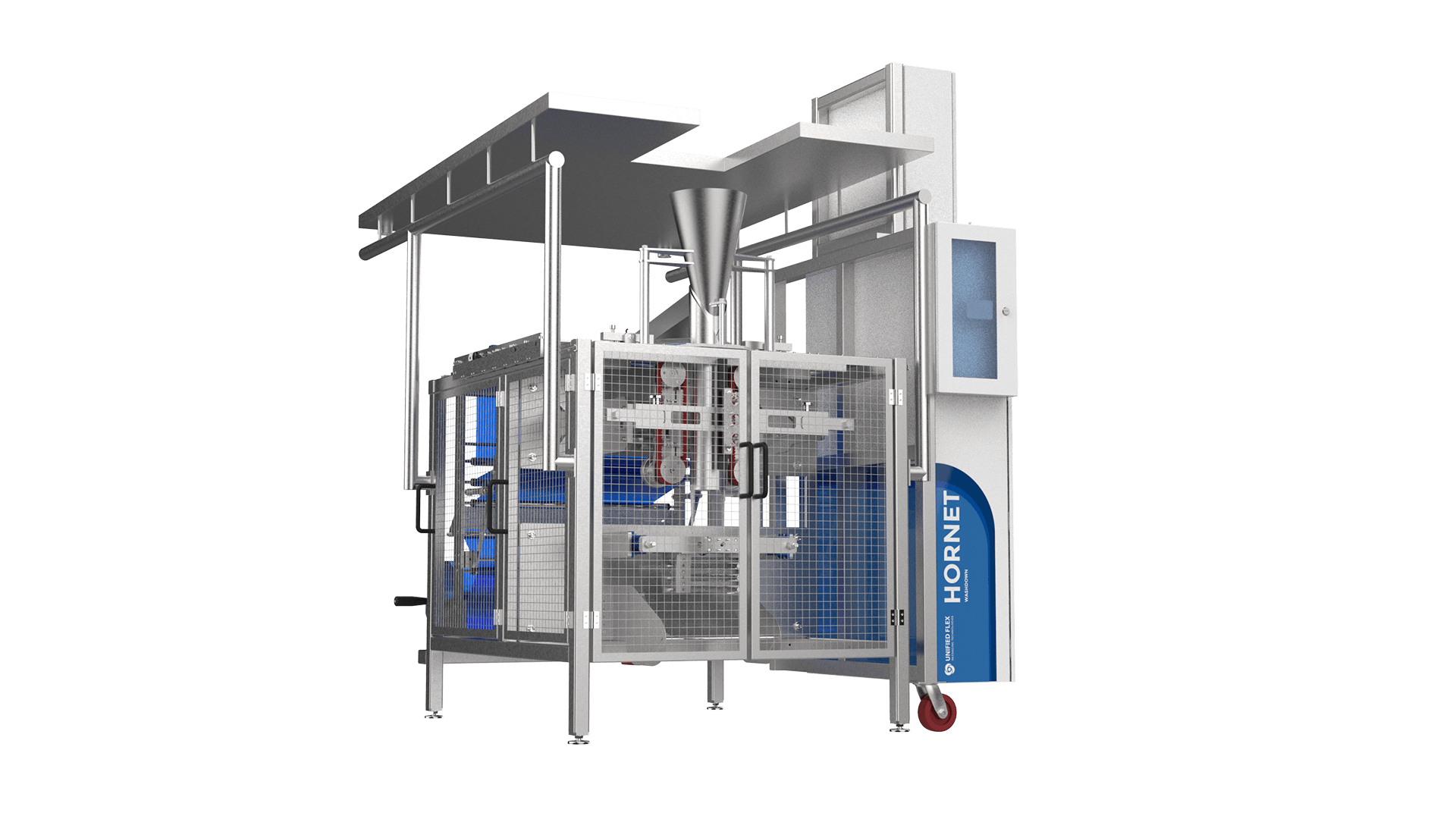

VFFS Intermittent Motion Machine - Premium

VFFS Vertobagger Hornet XL

minute max.

bag width

bag length

VFFS Vertobagger Hornet

minute max.

bag width

bag length

VFFS Vertobagger Hornet Washdown

minute max.

bag width

bag length

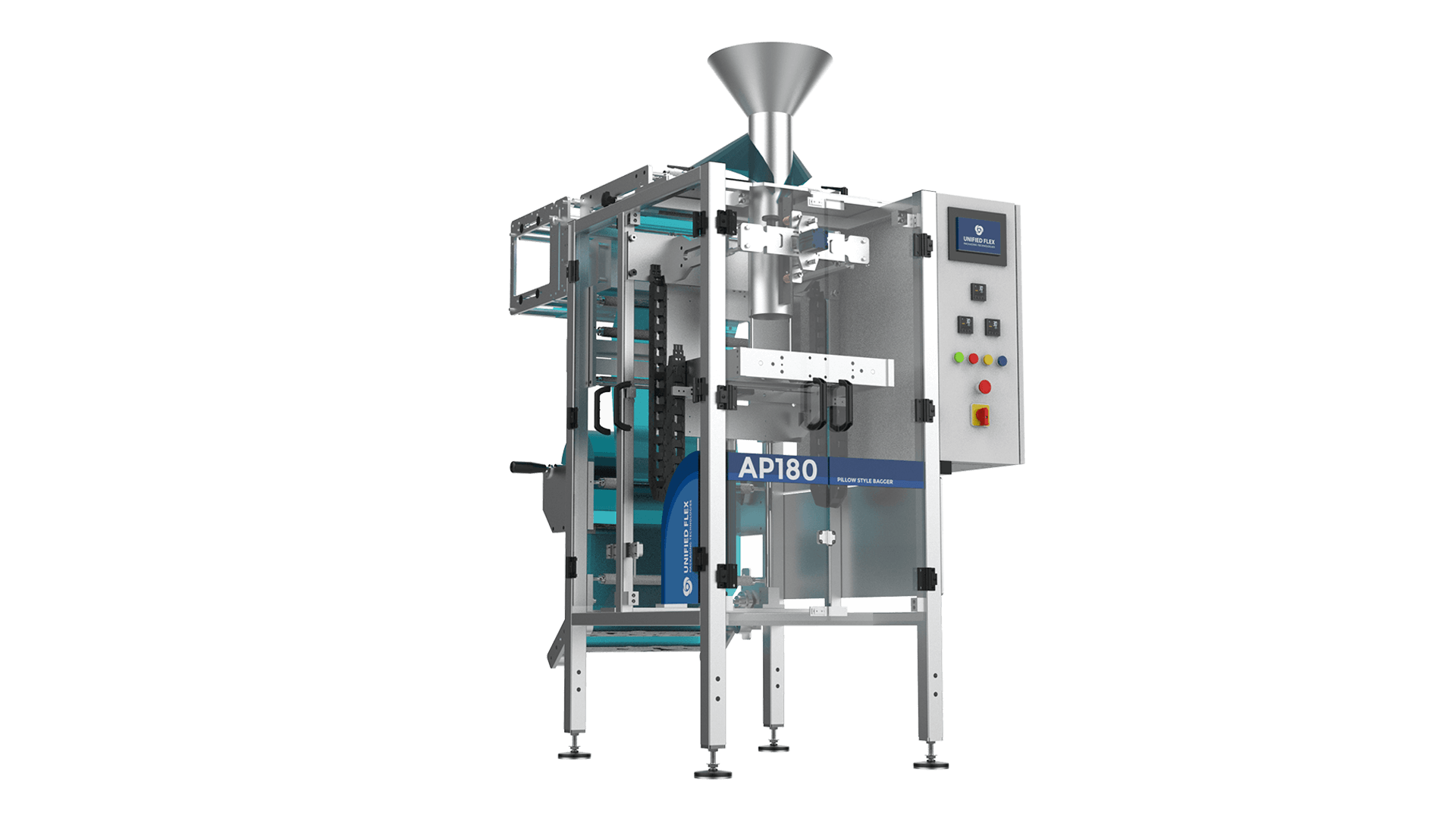

VFFS Intermittent Motion Machine - Economy

Auto Pouch Bagger AP-140

minute max.

bag width

bag length

VFFS Vertobagger Maverick

minute max.

bag width

bag length

Auto Pouch Bagger AP-180

minute max.

sachet width

sachet length

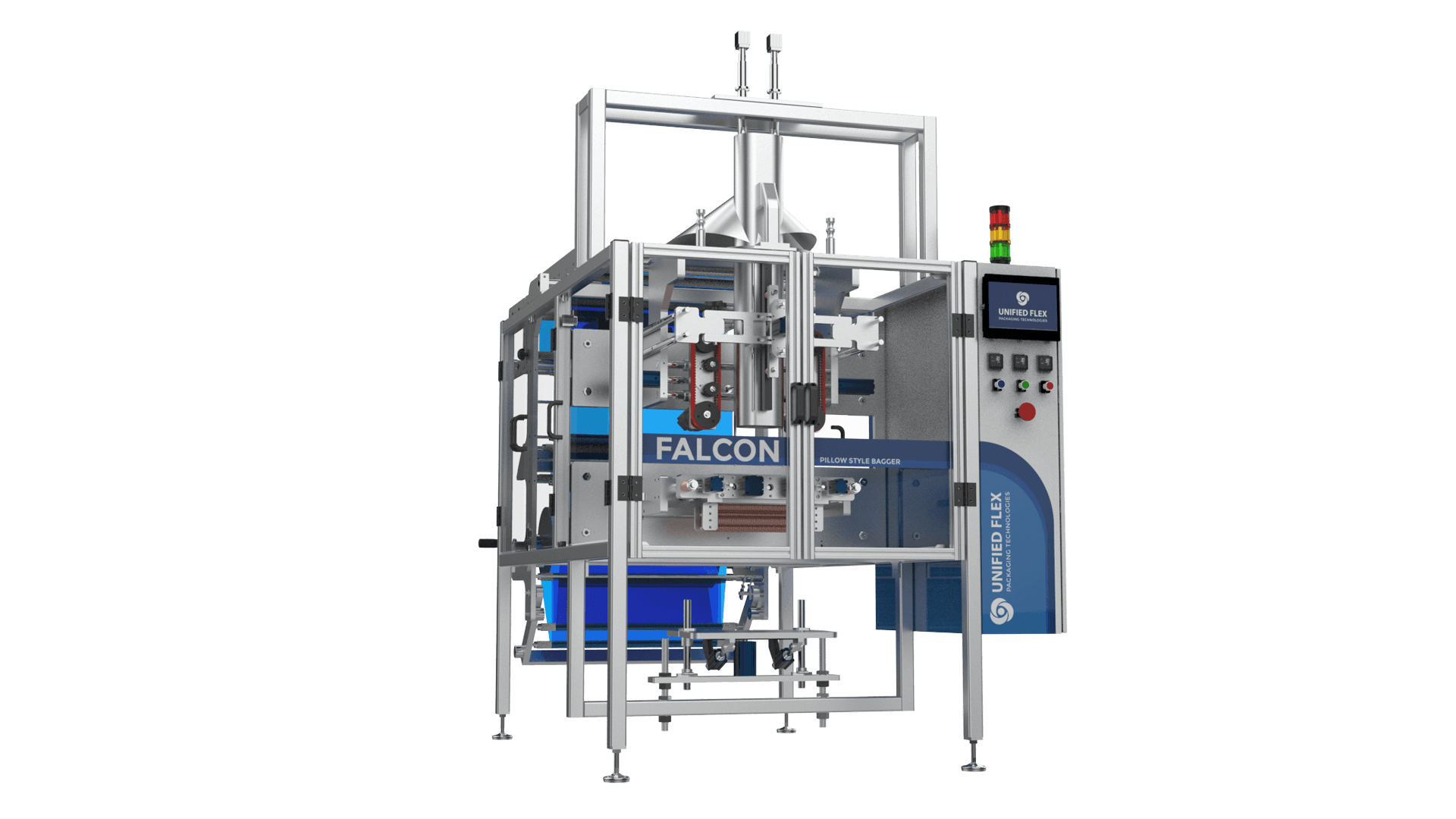

VFFS Vertobagger Falcon

minute max.

bag width

bag length

Stick Pack Machines

Auto Pouch Bagger AP-140 Stick Pack

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 300mm

minute max.

stick pack width

stick pack length

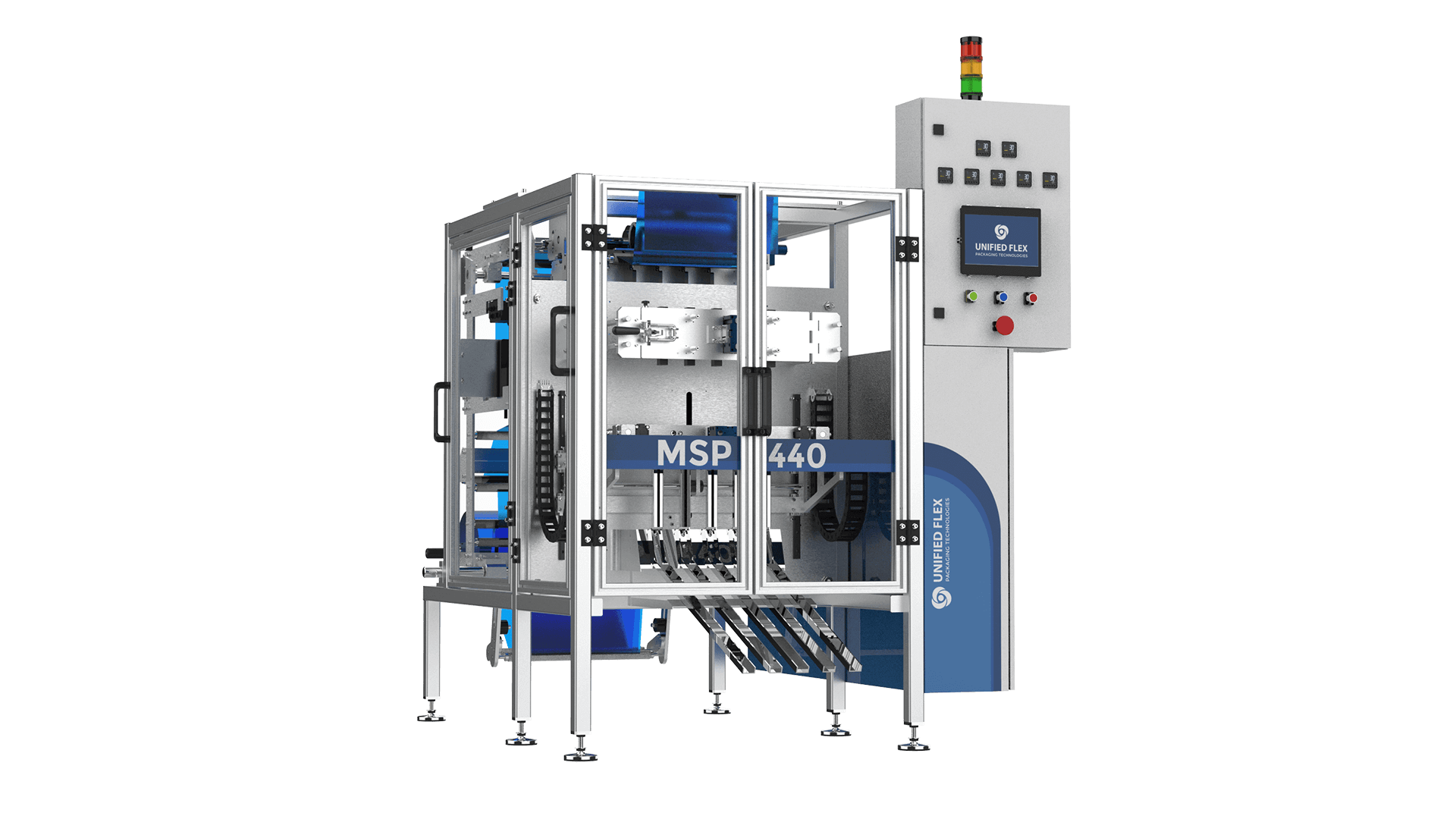

Multilane Stick Pack – MSP 440mm

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 800mm

minute max.

stick pack width

stick pack length

Sachet Machines

Auto Pouch Bagger AP-140 Sachet

minute max.

sachet width

sachet length

Auto Pouch Bagger AP-180 Sachet

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 406mm

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 508mm

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 813mm

minute max.

sachet width

sachet length

VFFS Continuous Motion Machines

VFFS Vertobagger 2.0

minute max.

bag width

bag length

VFFS Vertobagger 2.0 Ultrasonic

minute max.

bag width

bag length

Frequently Asked Questions

What is a VFFS machine?

A Vertical Form Fill Seal machine (VFFS) is an automated packaging system that forms, fills, and seals bags in a continuous vertical process. It starts with a roll of film, which is pulled into the machine, shaped into a bag, filled with the product, and then sealed.

VFFS machines are valued for their efficiency, speed, and versatility, making them a preferred choice across industries such as coffee, dairy, meat and cheese, cosmetics, and more. They can handle a variety of bag styles, product types, and packaging materials, ensuring consistent and high-quality packaging.

Want to improve your packaging process? Contact us today to find the right VFFS solution for your business.

How does a VFFS packaging machine work?

A Vertical Form Fill Seal machine (VFFS) efficiently automates the packaging process through the following streamlined steps:

9-Step VFFS Packaging Process

The VFFS process is fast, efficient, and precise, running multiple cycles per second to create sealed pouches. Here’s a breakdown of how it works:

1. Film Unwinding (Rollstock Loading)

A roll of flexible packaging film (plastic, laminated film, or foil) is loaded onto the mandrel and unrolled through the carriage assembly. Different machines have varied methods for film transportation.

2. Tension Control (Dancer Arm Movement)

A dancer arm moves up and down to maintain consistent tension as the film is fed through the machine, preventing wrinkles and misalignment.

3. Printing (Optional)

An integrated printer applies lot codes, expiration dates, barcodes, or branding as the film moves through the system.

4. Film Registration (Eye Mark Detection)

A photoelectric sensor detects eye marks (registration marks) printed on the film to ensure accurate positioning for precise cutting and sealing.

5. Film Alignment (Tracking & Adjustment)

A film tracking sensor confirms proper positioning. If misalignment occurs, an actuator automatically corrects the film’s path to maintain accuracy.

6. Forming the Bag

The film is then fed around a forming collar, shaping it into a cylindrical tube. A vertical seal is then created using heat sealing or ultrasonic sealing, forming either a lap seal or fin seal.

7. Bag Size Configuration

The width of the pouch is determined by the forming collar size. The length of the pouch can be adjusted anytime using machine settings. Intermittent motion machines have small pauses between each cycle, while continuous motion machines run non-stop at higher speeds.

8. Product Filling

The bag remains open at the top while the product is dispensed through a filling system, which varies based on the product type:

- Auger filler – for powders (e.g., coffee, flour).

- Volumetric cup filler – for granules (e.g., rice, beans).

- Piston pump – for liquids and pastes (e.g., sauces, gels).

- Multi-head weigher – for precision weighing (e.g., snacks, candies).

9. Sealing & Cutting (Final Step)

A horizontal seal is applied to close the top of the pouch. A cutting mechanism separates individual bags or keeps them in strips.

This automated, high-speed process ensures consistent, hygienic, and efficient packaging, making VFFS machines ideal for food, pharmaceuticals, cosmetics, and other industries.

Looking for an efficient packaging solution? Contact us today to explore how our VFFS machines can optimize your production process!

Are VFFS machines easy to maintain?

Yes, VFFS machines are designed for easy maintenance, but regular servicing is important to ensure optimal performance and longevity. Routine maintenance typically includes:

- Cleaning: Regularly removing product residue and dust to maintain hygiene and prevent malfunctions.

- Inspecting & Replacing Sealing Components: Checking sealing jaws, heating elements, and gaskets to ensure consistent and strong seals.

- Lubricating Moving Parts: Applying lubrication to rollers, gears, and mechanical components to reduce wear and friction.

- Checking & Calibrating Sensors: Ensuring photoelectric sensors, film tracking, and filling systems are properly aligned for accurate packaging.

- Replacing Worn-Out Parts: Monitoring belts, blades, cutting knives, and sealing jaws and replacing them as needed to prevent breakdowns.

Many modern VFFS machines come with automated diagnostics, error detection systems, and easy-access panels, making maintenance straightforward and minimizing downtime.

Looking for an easy-to-maintain VFFS machine? Contact us today to explore our VFFS packaging solutions for your packaging needs!

What are the advantages of using VFFS machines?

VFFS machines offer an efficient and cost-effective packaging solution with the following benefits:

Automated Efficiency: Speeds up production by automating forming, filling, and sealing while reducing labor costs.

Cost Savings: Optimizes material usage, lowers packaging expenses, and minimizes waste.

Versatility: Handles various bag styles and film types, making it suitable for powders, liquids, solids, and granules.

Reliable Sealing: Ensures product freshness and prevents contamination with precise heat or ultrasonic sealing technology.

Compact & User-Friendly: Saves space with a small footprint and features intuitive controls for quick changeovers.

Enhanced Features: Integrates with weighers, fillers, date coding, perforation, and resealable zippers for added functionality.

Unified Flex provides tailored VFFS solutions to enhance packaging efficiency and product quality. Contact us today to explore how we can optimize your packaging process!

Can vertical bagger machines/VFFS machines/ Vertical form fill seal machines handle different bag sizes?

Vertical Form Fill Seal (VFFS) machines are designed to handle a variety of bag sizes, accommodating different packaging requirements. The specific bag dimensions vary by model.

Here are some examples of Unified Flex’s VFFS machines and their bag size capabilities:

Auto Pouch Bagger AP-140: Designed for smaller bag sizes, it can produce bags up to 4.5 inches in width and 7.5 inches in length.

VFFS Vertobagger Hornet: Handles bags up to 13 inches wide and 20 inches long.

VFFS Vertobagger Maverick: Suitable for bags up to 10 inches in width and 12 inches in length.

VFFS Vertobagger Hornet XL: Produces bags up to 18 inches in width and 30 inches in length.

Adjusting the bag size typically involves changing the forming tube and making machine setting adjustments to match the desired bag dimensions. This flexibility allows manufacturers to package products in various quantities and sizes efficiently.

For detailed specifications and to determine the best machine for your specific bag size requirements, contact us.

What Role Does a VFFS Machine Play in Modern Packaging?

A vffs machine plays a vital role in modern packaging by helping brands meet today’s demands for speed, flexibility, and shelf appeal. At Unified Flex, our VFFS machines are built to handle a variety of products, from powders and granules to IQF foods, while producing different bag styles. This allows manufacturers to adapt quickly to market changes, reduce packaging waste, and deliver consistent, retail-ready packaging that protects product quality and boosts operational efficiency.

What are the core components of a vertical form fill and seal machine and their functions?

Unified Flex vertical form fill and seal machine features key components, including a film unwinding system, a forming tube and shoulder for bag shaping, precision filling systems, and advanced sealing jaws. These components work seamlessly to create consistent, high-quality packages while minimizing waste and downtime.

How do you evaluate vertical form fill seal machine manufacturers when selecting a supplier?

When choosing vertical form fill seal machine manufacturers, focus on proven performance, customization, and dependable support. Unified Flex stands out by offering tailor-made VFFS machines designed to meet your specific product and packaging needs, backed by expert engineering, comprehensive training, and dedicated after-sales service to ensure long-term success.

What key factors should you consider before purchasing a VFFS packaging machine?

Before investing in a VFFS packaging machine, consider your product type, desired bag styles, production speed, and packaging material. Unified Flex offers tailored solutions, ensuring you get a machine designed to meet your exact operational and efficiency goals. For more details, contact us now.

What types of bag styles can a VFFS machine produce?

Unified Flex VFFS machines can produce a wide range of bag styles, including pillow bags, gusseted bags, stick packs, and more. This versatility helps brands deliver attractive, functional packaging that meets both retail and bulk packaging needs.

Which packaging materials and features can be used with a vertical form fill seal packaging machine?

Unified Flex VFFS machines work with a variety of high-performance packaging materials designed to protect product quality and extend shelf life. These include high-barrier laminations, which prevent moisture, oxygen, and light from compromising freshness, ideal for foods, powders, and pharmaceuticals. Metalized films such as BoPET or BOPP offer added strength and protection, while OPP laminations provide clarity, durability, and cost efficiency. Our machines also support features like resealable zippers, easy-open options, and Modified Atmosphere Packaging (MAP) to deliver durable, user-friendly packaging solutions.

Vertical Form Fill Seal Machines That Power Your Productivity

Are you a plant engineer looking to streamline operations? A production manager trying to scale output? Or maybe you’re a business owner ready to launch a new product line? No matter your role, one thing’s for sure—you need a packaging solution that’s fast, reliable, and built for long-term performance. This is exactly what Unified Flex’s VFFS machines are built for.

No matter your industry—food & beverage, pharmaceuticals, cosmetics, pet products, or consumer goods—our vertical form fill seal machines are designed to package it all, from powders and liquids to solids and more. Made for speed, precision, and flexibility, they’re the workhorses your production line has been waiting for.

We get it—your time is valuable, your equipment needs to work perfectly, and any downtime is a problem. That’s why our automatic VFFS systems are designed to deliver consistent performance with minimal maintenance, allowing you to focus on what really matters: getting quality products out the door, fast.

Let’s take your packaging process to the next level—with the right VFFS packaging machine.

What is a VFFS Machine?

A vertical form fill and seal machine is a fully automated system that forms, fills, and seals packaging in one continuous vertical motion. Imagine taking a roll of flat film, shaping it into a bag, filling it with your product, and sealing it—all in seconds. That’s exactly what our machines do.

It’s a simple, smart solution for high-speed, high-volume packaging—and it’s trusted across industries like:

Who Uses VFFS Machines?

If you’re packaging powders, liquids, or solid products, a Vertical Form Fill Seal (VFFS) machine can streamline your operations and boost efficiency. Unified Flex serves a broad array of industries, including food and beverage manufacturers (like those producing coffee, snacks, sauces, and rice), pharmaceutical and nutraceutical producers (handling pills, powders, and supplements), cosmetic and personal care brands (for creams, gels, and travel-size products), as well as chemical and industrial suppliers. Our VFFS packaging equipment empowers engineers, managers, and business leaders with the strong functionality and efficiency needed to meet growth targets and stay competitive.

Why Choose Unified Flex VFFS Machines?

We don’t just sell machines. We build solutions that match your production goals. At Unified Flex, we offer a wide range of 18 VFFS models across five series, including Premium, Economy, Stick Pack, Sachet, and Continuous Motion machines.

Here’s what makes our vertical form fill seal machinery stand out:

- Speed: From 40 to 1000 bags per minute

- Multiple Lanes:Choose from 1 to 20 lanes based on your volume

- Max Web Width: Up to 37 inches (939.8 mm)

- Max Cycles Per Minute: Up to 150 for continuous motion models

From small-batch startups to large-scale manufacturers—we’ve got the right vertical form fill seal machine for your production line.

VFFS Machines to Match Your Needs

We present vertical form fill seal machines in five categories—each suited to different production goals and product types.

- VFFS Intermittent Motion – Premium Series

Our Premium Series of intermittent motion VFFS machines is built for manufacturers who require consistent, top-quality results. These machines operate in a stop-and-go motion, pausing momentarily at each cycle to ensure precise filling, sealing, and bag forming. This added control makes them ideal for packaging products that require gentle handling or exact portioning.

Ideal for:

- Larger food products

- Bulk snacks

- Industrial and retail packaging

Premium Machine Models:

Model | Max Output | Max Bag Width | Max Bag Length |

Hornet XL | Up to 50 bags/minute | 18 inches | 30 inches |

Hornet | Up to 80 bags/minute | 13 inches | 20 inches |

Hornet Washdown | Up to 60 bags/minute | 13 inches | 20 inches |

- VFFS Intermittent Motion – Economy Series

Looking to upgrade from manual filling or semi-automated systems? Our Economy Series VFFS machines are perfect for small to mid-sized businesses that want dependable performance without the higher price point. These machines offer the same core functionality as our premium models but are optimized for lower output operations.

Ideal for:

- Startups and mid-size operations

- Snacks, dry goods, powders

- Retail-ready pouch packaging

Economy Machine Models:

Model | Max Output | Max Bag Width | Max Bag Length |

AP-140 | Up to 40 bags/minute | 4.5 inches | 7.5 inches |

Vertobagger Maverick | Up to 80 bags/minute | 10 inches | 12 inches |

AP-180 | Up to 40 bags/minute | 8.5 inches | 11.5 inches |

Vertobagger Falcon | Up to 100 bags/minute | 13 inches | 20 inches |

- Stick Pack Machines

Today’s consumers love convenience—and stick packs are one of the most popular formats for single-use and on-the-go products. Our Stick Pack Machines are designed to produce narrow, elongated pouches with precision, sealing reliability, and high-speed output. Available in 1 to 16 lanes, these VFFS packaging machines can scale with your business.

Ideal for:

- Coffee sticks

- Nutritional powders

- Gels and liquids

Stick Pack Machines Models:

Model | Max Output | Max Stick Pack Width | Max Stick Pack Length |

AP-140 Stick Pack | Up to 40 stick packs/minute | 1.5 inches | 7.5 inches |

MSP 300 mm | Up to 300 stick packs/minute | 1.5 inches | 8 inches |

MSP 440 mm | Up to 400 stick packs/minute | 1.5 inches | 8 inches |

MSP 800 mm | Up to 800 stick packs/minute | 1.5 inches | 8 inches |

- Sachet Machines

If you’re looking to create compact 3-side or 4-side sealed sachets, our Sachet Machines offer the ideal VFFS packaging solution. Ease of use, low maintenance, and smooth operation make them a reliable choice for continuous production. With robust construction and precise assembly, our sachet machines deliver consistent performance and long-term durability.

Ideal for:

- Sauces and creams

- Spices, coffee, sugar

- Medications and supplements

Sachet Machines Models:

Model | Max Output | Max Sachet Width | Max Sachet Length |

AP-140 Sachet | Up to 40 sachets/minute | 4.5 inches | 7.5 inches |

AP-180 Sachet | Up to 40 sachets/minute | 8.5 inches | 11.5 inches |

MSB 406 mm | Up to 500 sachets/minute | 4 inches | 12 inches |

MSB 508 mm | Up to 600 sachets/minute | 5 inches | 12 inches |

MSB 813 mm | Up to 1000 sachets/minute | 8 inches | 12 inches |

- VFFS Continuous Motion Machines

If your facility requires high-speed, uninterrupted production, our Continuous Motion VFFS machines are the right choice. These machines don’t pause between cycles—instead, they operate in a fluid, nonstop motion, making them capable of handling up to 150 cycles per minute.

Ideal for:

- 24/7 high-output manufacturing

- Large-scale food production (snacks, grains, frozen foods)

- Fast-moving consumer goods (FMCG)

VFFS Continuous Motion Machines Models:

Model | Max Output | Max Bag Width | Max Bag Length |

Vertobagger 2.0 | Up to 150 bags/minute | 13 inches | 15 inches |

Vertobagger 2.0 Ultrasonic | Up to 150 bags/minute | 13 inches | 15 inches |

Reasons to Invest in a VFFS Packaging Machine

Investing in a vertical form fill seal machine is a strategic decision for many businesses looking to enhance their production capabilities and overall efficiency. Here are convincing reasons why businesses choose to invest in VFFS technology:

- Fully automates forming, filling, and sealing

- Speeds up production and reduces labor costs

- Minimizes material waste and packaging expenses

- Maintains product freshness with airtight seals

- Supports high-volume, continuous output

- Handles powders, liquids, solids, and granules

- Produces neat, consistent, retail-ready packaging

- Compact design saves space on the floor

- Quick changeovers with user-friendly controls

- Easily integrates with weighers, coders, and zippers

Ready to Improve Your Packaging Line?

If you’re serious about boosting productivity, reducing waste, and improving packaging quality, Unified Flex has the VFFS machine for you.

Let’s talk about your goals—be it snacks, vitamins, sauces, or skincare products you’re packaging. We’ll guide you to the right vertical form fill sealing machine model and support your team from setup to scale-up.

Speak with our team today to find the VFFS machine that fits your packaging goals.