Spouted pouch Filler and Capper

Spouted pouch Filler and Capper

Increase Efficiency and Reduce Waste in Liquid Fill Application

Designed to optimize efficiency and reduce waste, our advanced Spouted Pouch Filling & Capping machines can seamlessly fill, and seal spouted pouches with precision.

From liquids to semi-liquids, our versatile Spout Pouch Filling & Capping machines cater to a wide range of applications, including dressings, sauces, and juices, as well as liquid soaps, shampoos, and detergents. Equipped with a “No Pouch- No Fill mechanism” our Spout Pouch Filling Machines minimize spillage. Additionally, the “Pick-&-Replace” feature ensures a smooth transition of pre-made pouches on a rotary table, removing the need for individual loading. Easy integration with piston fillers and user-friendly design makes it an ideal choice for complete liquid packaging solutions.

Investing in a Spout Pouch Filling & Capping machine will reduce the cost of manual labor and minimize the risk of errors ensuring a consistent production process with precise filling, resulting in standardized product quality that satisfies both you and your customers.

No. of Filling Head

Pouches Per Minute

Minimum Fill Volume

Maximum Fill Volume

Low Volume

Spouted Pouch Filler & Capper MS-1

minute max.

volume

volume

Medium Volume

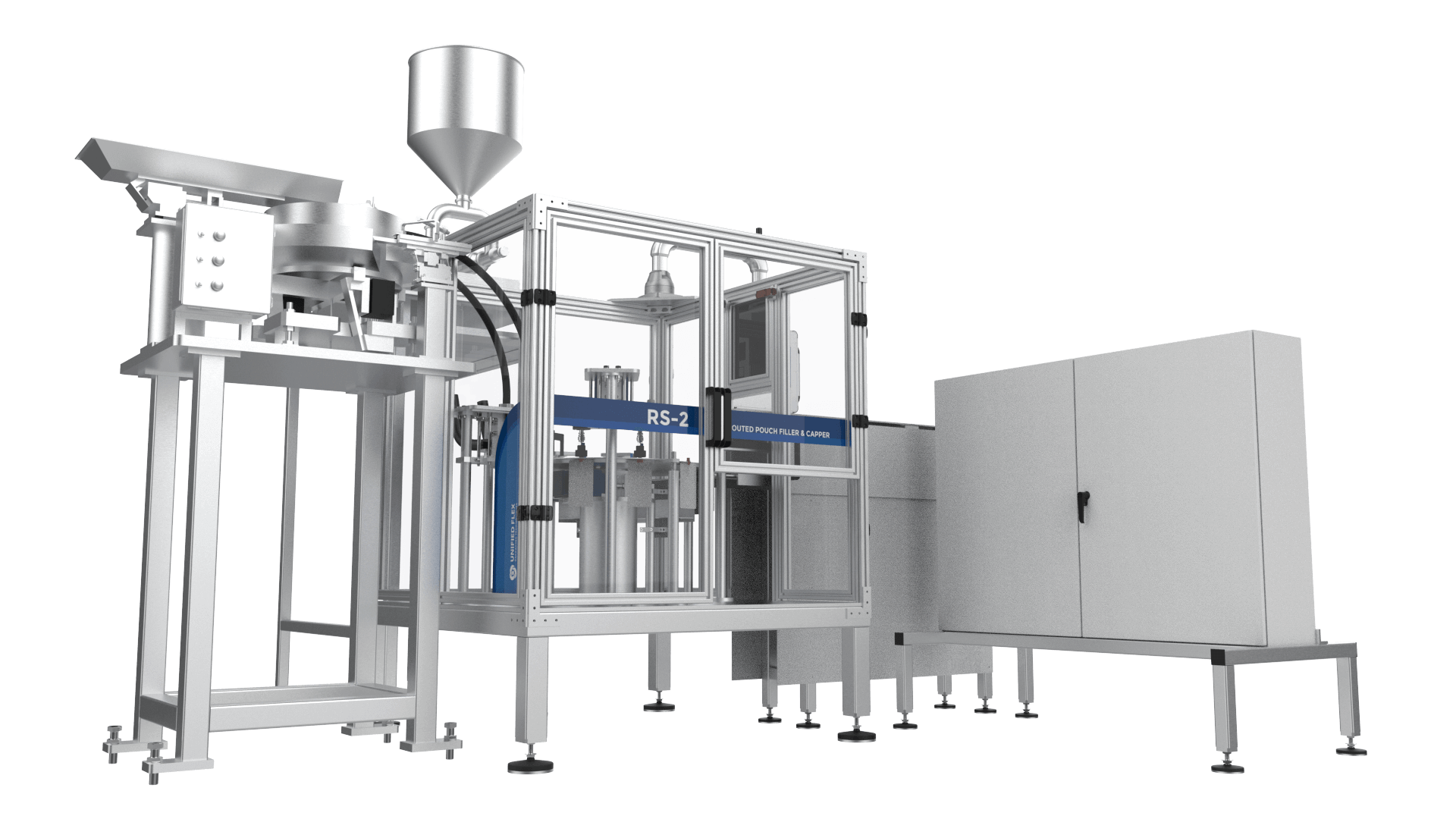

Spouted Pouch Filler & Capper RS-2

minute max.

volume

volume

High Volume

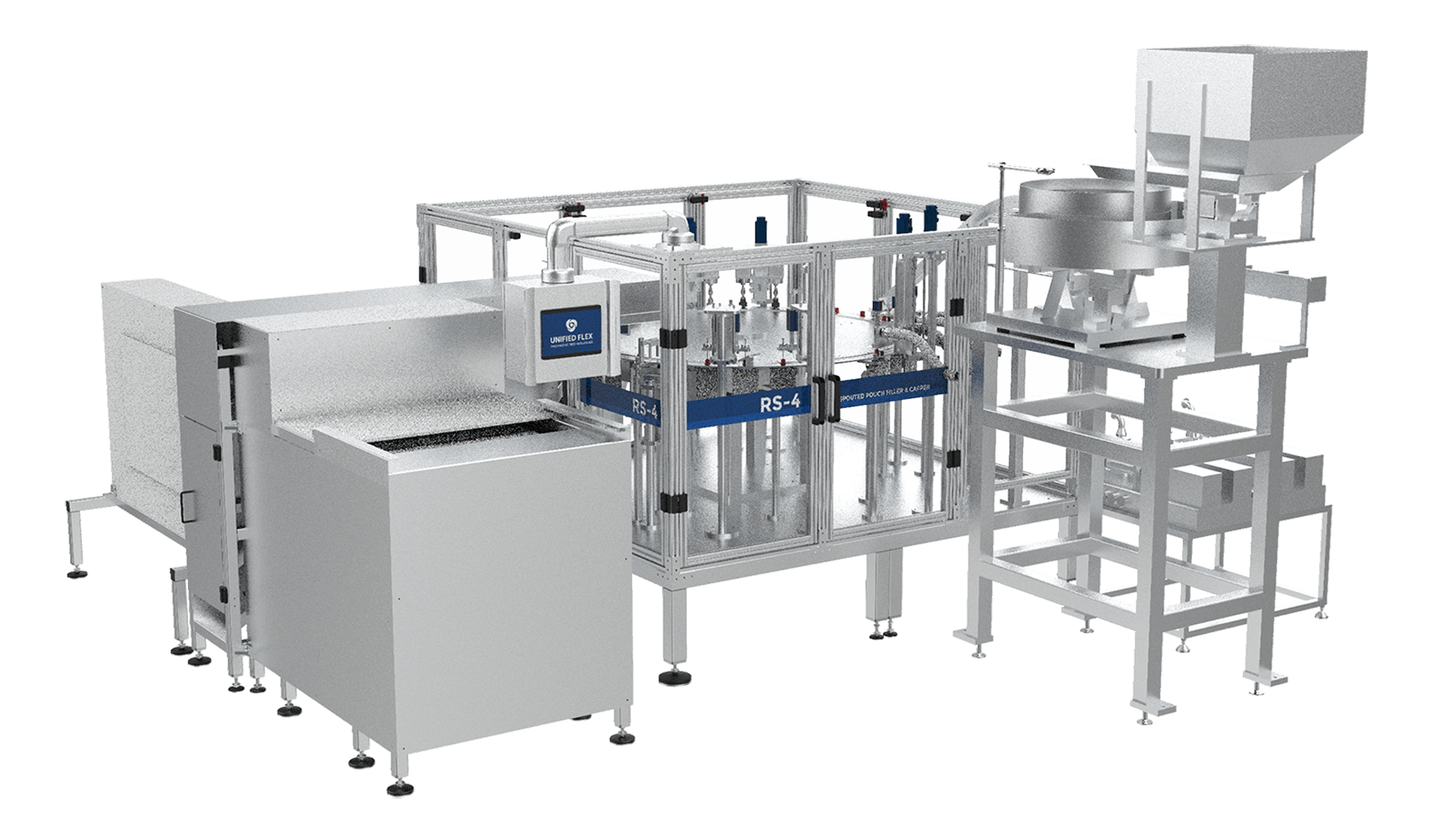

Spouted Pouch Filler & Capper RS-4

minute max.

volume

volume

Frequently Asked Questions

What is a spouted filler and capper machine?

A spouted pouch filler and capper machine is an automated system designed to fill liquid or semi-liquid products into preformed pouches with spouts and securely apply caps. These machines are commonly used for beverages, sauces, baby food, beauty and cosmetics, sauces, cleaning products, and other liquid-based items that require leak-proof and resealable packaging.

What are the applications of spouted filling and capping machines?

A spouted pouch filler and capper machine is designed to efficiently package liquid and semi-liquid products in preformed spouted pouches. This process ensures accurate filling, airtight sealing, and secure capping, making it ideal for a wide range of industries.

Key Uses of Spouted Pouch Filling and Capping Machines:

1. Food & Beverage Industry

- Juices, smoothies, and dairy products: Ensures hygienic, spill-free packaging.

- Sauces, dressings, and condiments: Provides convenient, easy-pour spouted pouches.

- Baby food and purees: Maintains freshness and ease of use.

2. Personal Care & Cosmetics

- Shampoos, conditioners, and lotions: Allows for squeezable, mess-free dispensing.

- Liquid soaps and hand sanitizers: Provides a portable, resealable packaging solution.

3. Household & Industrial Products

- Detergents and cleaning liquids: Prevents leaks and improves product storage.

- Lubricants and automotive fluids: Provides a controlled, spill-free dispensing solution for compatible fluid types.

4. Pharmaceuticals & Nutraceuticals

- Energy gels and nutritional supplements: Offers a single-serve, convenient pouch.

- Medical-grade solutions: Supports secure, tamper-evident packaging for liquid-based formulations.

Looking for a reliable spouted pouch filling solution? Contact Unified Flex today!

How do spouted pouch machines ensure secure filling without leaks or overflows?

Spouted pouch filling and capping machines use servo-controlled filling, automated sealing, and torque-regulated capping to ensure precise, spill-free, and airtight packaging. These features help maintain product integrity, prevent waste, and extend shelf life.

1. Precise Filling Mechanisms

- Piston Fillers & Pump-Based Systems: Accurately dispense viscous and free-flowing liquids, including those containing particulates.

- Servo-Controlled Filling: Adjustable speed settings for precise dispensing of thin liquids, thick purees, and high-viscosity products.

- No-Pouch, No-Fill Technology: Prevents waste by ensuring filling only occurs when a pouch is correctly positioned.

2. Secure Capping for Leak-Proof Packaging

- Independent Torque-Controlled Capping Heads: Ensures secure, consistent cap tightening, preventing leaks or over-tightening.

- Tamper-Evident Cap Integration: Supports tamper-proof packaging when used with compatible caps.

- Air Removal & Nitrogen Flushing (Optional): Eliminates excess air inside the pouch to prevent spoilage and maintain product quality.

3. Advanced Leak Prevention & Quality Control

- Precision Rotary Indexing: Ensures accurate pouch positioning for consistent filling and sealing.

- Precision Heat Sealing: Forms strong, airtight seals to prevent leaks.

- Heavy-Duty Stainless Steel Construction: Built for hygienic and long-lasting performance.

Need a high-performance spouted pouch packaging solution? Contact Unified Flex today!

Are spouted pouch filling and capping machines compatible with a variety of spout and cap designs?

Yes, spouted pouch filling and capping machines are designed to handle a wide range of spout and cap styles, ensuring flexibility for different packaging requirements. These machines can accommodate various pouch sizes, spout positions, and cap configurations, making them ideal for food, beverage, cosmetics, and industrial applications.

1. Compatibility with Spout Positions

- Center Spouted Pouches: Common for juices, baby food, and liquid supplements.

- Corner Spouted Pouches: Often used for sauces, condiments, and cleaning products to provide easy pouring.

2. Support for Different Cap Designs

- Standard Screw Caps: Secure, leak-proof closures for liquid and semi-liquid products.

- Tamper-Evident Caps: Ensure product integrity and safety by providing a visible security seal.

- Flip-Top Caps: Convenient for single-handed dispensing, commonly used for personal care products.

- Custom Cap Compatibility: Machines allow for tooling adjustments to support various cap designs.

3. Precision Filling and Capping for Leak-Proof Seals

- Torque-Controlled Capping Heads: Ensure accurate torque adjustment to prevent over-tightening or loose caps.

- No-Pouch, No-Fill Technology: Prevents spills and ensures the product is only dispensed into correctly positioned pouches.

- Piston and Pump Integration: Handles viscous and free-flowing liquids, even those containing particulates.

Looking for a reliable spouted pouch packaging solution? Contact Unified Flex today!

Can spouted pouch filling and capping machines handle hot-fill, cold-fill, and aseptic-filling processes?

Yes! Spouted pouch filling and capping machines are versatile and can accommodate hot-fill, cold-fill, and aseptic-filling applications, depending on product requirements. These filling methods help ensure product safety, extend shelf life, and maintain quality.

1. Hot-Fill Process (For High-Temperature Liquid Filling)

- Suitable for juices, sauces, soups, and pasteurized beverages requiring heat treatment to kill bacteria.

- Machines support hot-fill applications using heat-resistant pouches, spouts, and sealing components.

- Extends shelf life without preservatives.

2. Cold-Fill Process (For Chilled or Refrigerated Products)

- Ideal for dairy products, smoothies, cold brew coffee, and energy drinks.

- Maintains freshness, flavor, and texture without heat exposure.

- Optimized for efficient filling of chilled liquids while preserving product quality.

3. Aseptic Filling Process (For Sterile, Shelf-Stable Packaging)*

- Required for milk-based drinks, plant-based beverages, baby food, and pharmaceutical liquids.

- Uses sterilized pouches, spouts, and caps to maintain long shelf life without refrigeration.

- Ensures contamination-free filling in ultra-clean, sterile environments.

Note: Aseptic filling requires additional sterilization systems. Check with Unified Flex for machine compatibility.

Need a reliable filling solution for your spouted pouches? Contact Unified Flex today!

What is the production capacity of a spouted pouch filler and capper machine?

The production capacity of a spouted pouch filler and capper machine depends on the model, number of filling heads, and automation level. These machines are designed to handle various speeds and pouch sizes, making them suitable for low, medium, and high-volume production.

Below are examples of Unified Flex’s spouted pouch filling and capping models, tailored for different production needs.

1. Low-Volume Production – Spoutpack MS-1

- Ideal for small-batch operations, startups, and specialty products.

- Typically fills and caps up to 12 pouches per minute.

- Best for artisan juices, baby food, cosmetics, and sauces.

2. Medium-Volume Production – Spoutpack RS-2

- Suitable for growing businesses with moderate demand.

- Capable of filling and capping up to 40 pouches per minute.

- Used for dairy products, energy drinks, and household liquids.

3. High-Volume Production – Spoutpack RS-4

- Designed for mass production and large-scale manufacturing.

- Can process up to 80 pouches per minute with multi-head fillers.

- Commonly used for juices, condiments, liquid detergents, and industrial applications.

Looking for the right spouted pouch packaging solution? Contact Unified Flex today!

Are spouted pouch filling and capping machines compatible with eco-friendly pouch materials and caps?

Yes! Spouted pouch filling and capping machines are designed to be compatible with eco-friendly pouch materials and sustainable cap options, helping businesses meet environmental goals without compromising packaging quality.

1. Eco-Friendly Pouch Materials Supported

- Recyclable Plastic Films: Uses mono-material polyethylene (PE) or polypropylene (PP), making pouches easier to recycle.

- Compostable & Biodegradable Films: Includes plant-based materials like PLA (polylactic acid), which may require specific sealing adjustments for compatibility.

- Paper-Based Laminates: Provides a renewable alternative while maintaining durability and product protection.

2. Sustainable Spout & Cap Options

- Recyclable Caps: Made from single-type plastic (e.g., PP or HDPE), improving recyclability.

- Bio-Based Caps: Made from renewable materials like sugarcane, offering a reduced carbon footprint while maintaining recyclability.

- Lightweight & Minimalist Designs: Reduces plastic usage while maintaining a secure, leak-proof seal.

Find an Eco-Friendly Pouch Packaging Solution with Unified Flex

Unified Flex’s spouted pouch filling and capping machines support a wide range of eco-friendly pouch materials and caps, ensuring sustainable, high-quality, and efficient packaging solutions.

Looking for an eco-friendly pouch packaging solution? Contact Unified Flex today!

Efficient Filling & Capping Machines for Liquid Packaging Needs

If you’re in the food, beverage, or personal care industry, you already know the struggle—leaky pouches, slow filling lines, wasted product, and production delays. Sound familiar? You’re not alone.

Maybe you’re a manufacturer trying to scale up, a co-packer handling multiple products, or a brand owner looking to level up your packaging game. Either way, the right equipment can seriously change the game.

At Unified Flex, we understand that in the modern-day manufacturing hustle, every second—and every drop—counts. That’s why our spouted pouch filler machines are built not just to meet expectations, but to raise the bar.

From juices and dressings to baby food, lotions, and industrial liquids, our machines deliver clean, consistent, and efficient packaging—so you can focus on growing your business, not fixing equipment problems.

Ready to reduce waste, boost output, and keep the product safe and fresh? Let’s dive into the machines that can make it happen.

What Is a Spouted Pouch Filler and Capper Machine?

A spouted pouch filling and packing machine is a fully automated system that fills liquid or semi-liquid products into pre-formed pouches with built-in spouts, then applies a secure, tamper-evident cap.

It’s fast, clean, and ideal for packaging everything from juice drinks to industrial cleaners.

Real-World Examples:

- Gerber baby food pouches

- Capri Sun with resealable tops

- GU Energy performance gels

- Method liquid soap refills

- Chobani yogurt smoothies

Struggling with Inefficient Filling Systems?

Let’s be honest—manual filling lines are a productivity killer. They’re inconsistent, messy, and slow. We’ve helped customers who were:

- Manually capping hundreds of pouches a day

- Dealing with returns from leaky shipments

- Losing product due to spills and inaccurate fill volumes

Imagine preventing all that with features like:

- Servo-controlled filling for precise volume control

- “No-Pouch, No-Fill” mechanism to eliminate product loss

- Pick-and-Replace rotary pouch handling to remove manual loading

- Torque-regulated capping for consistent, leak-proof results

Three Advanced Machines to Meet Your Output Goals

Check our three models—designed for small to high-volume production.

Low Volume Spouted Pouch Filler & Capper

Compact, efficient, and highly adaptable, the MS-1 is perfect for short runs and small-batch production.

Ideal for:

- Startups and pilot-scale operations

- Specialty product lines (e.g., oils, sauces)

- Lab testing or seasonal launches

- Small batch contract packaging

- R&D and product trials

MS-1 Specifications

Model | Max Speed | Min Fill Volume | Max Fill Volume |

MS-1 | 12 pouches/min | 50 mL | 2 L |

Medium Volume Spouted Pouch Filler & Capper

With dual filling heads, the RS-2 boosts productivity without compromising accuracy. It’s perfect for a broad range of food-grade and non-food liquids.

Ideal for:

- Mid-size food and non-food packaging

- Expansion from manual to semi-automated lines

- Contract packaging companies

- Cosmetics and personal care manufacturers

- Household chemical production

RS-2 Specifications

Model | Max Speed | Min Fill Volume | Max Fill Volume |

RS-2 | 40 pouches/min | 100 mL | 2 L |

High Volume Spouted Pouch Filler & Capper

Built for high-speed, industrial-scale production, the RS-4 fills and caps four pouches at once—making it the ideal solution for fast-moving consumer goods and large-batch manufacturers.

Ideal for:

- Large-scale food processing facilities

- Fast-moving consumer product lines

- Industrial packaging of oils, detergents, lotions

- High-speed contract manufacturing

- Large-volume export packaging

RS-4 Specifications

Model | Max Speed | Min Fill Volume | Max Fill Volume |

RS-4 | 80 pouches/min | 20 mL | 2 L |

Compatible with Different Spout and Cap Designs

Product packaging is a key part of your brand identity, and our systems support that flexibility. Whether your application requires top spouts, corner spouts, tamper-evident caps, or flip-tops, our automatic spout pouch filling machines are ready to adapt.

We Support:

- Top and corner-spouted pouch configurations

- Standard screw caps

- Tamper-evident and child-resistant caps

- Flip-top dispensing caps

- Custom-cap tooling upon request

Example: A cosmetic brand paired its lotion pouches with a custom gold flip-top cap—sales increased after customers praised the mess-free dispensing.

Unified Flex systems are also compatible with different pouch sizes and shapes, allowing your team to produce product lines with multiple SKUs using the same equipment.

What Filling Method Best Suits Your Product?

Unified Flex’s spout pouch filling machines are designed for flexibility. Depending on your product requirements, you can run:

- Hot-Fill: Ideal for sauces, soups, and pasteurized drinks.

- Cold-Fill: Perfect for dairy, juices, and energy beverages.

- Aseptic Fill (optional): For sterile packaging of nutraceuticals, baby food, and long-shelf-life products without preservatives.

- Question to consider: Are you using preservatives just to survive long shipping times? Aseptic filling might be the better route.

How Co-Packers Solved Their Packaging Problems

A mid-size co-packer in Wisconsin was struggling with slow, messy bottle filling and long changeovers between products like baby food and dressings. After switching to the RS-2 Spouted Pouch Filler & Capper, they finally had clean fills, secure caps, and faster product switches. Clients loved the sleek pouch packaging and started requesting it by default.

Another win? A skincare brand eliminated messy leaks during shipping, and a soup company finally kept up with seasonal demand—all due to smarter, more reliable pouch packaging.

Eco-Friendly? Absolutely

Unified Flex’s pouch filling machines are compatible with a wide range of sustainable pouch and cap materials, helping you meet packaging regulations and customer expectations:

- Recyclable monomaterial films (PE, PP)

- Compostable laminates (e.g., PLA)

- Bio-based caps from sugarcane or biodegradable polymers

Stat: Flexible pouches use 50-70% less plastic than rigid containers.

Let’s Optimize Your Liquid Packaging Line

Be it launching a new product, upgrading from manual operations, or scaling production, Unified Flex is ready to help you automate with confidence.

Connect with us today and explore the right pouch filling and packing machine for your operation.