Stand-Up Pouch Bagging Machines

Stand-Up Pouch Bagging Machines

Versatile and Easy-To-Use Stand Up Pouch MachineS

Unified Flex offers Stand Up Pouch Machines at speeds ranging from 15 to 40 bags per minute with a variety of optional features that are sure to meet the distinct packaging needs of your dynamic market.

These machines can package a wide array of products, both solid and liquid, such as beverages, snack foods, coffee, cheese, dairy and meats, cannabis, and more in convenient, portable, eco-friendly packaging.

You can count on Unified Flex to deliver intelligent stand up pouch filling machines, economical solutions, and dependable systems for all your packaging needs.

Have a unique packaging need? To discuss how Unified Flex can help you achieve the success you desire, Get a Free Consultation.

Bags Per Min

Maximum Bag Width

Maximum Bag Length

Bag Style Possibilities

Low Volume

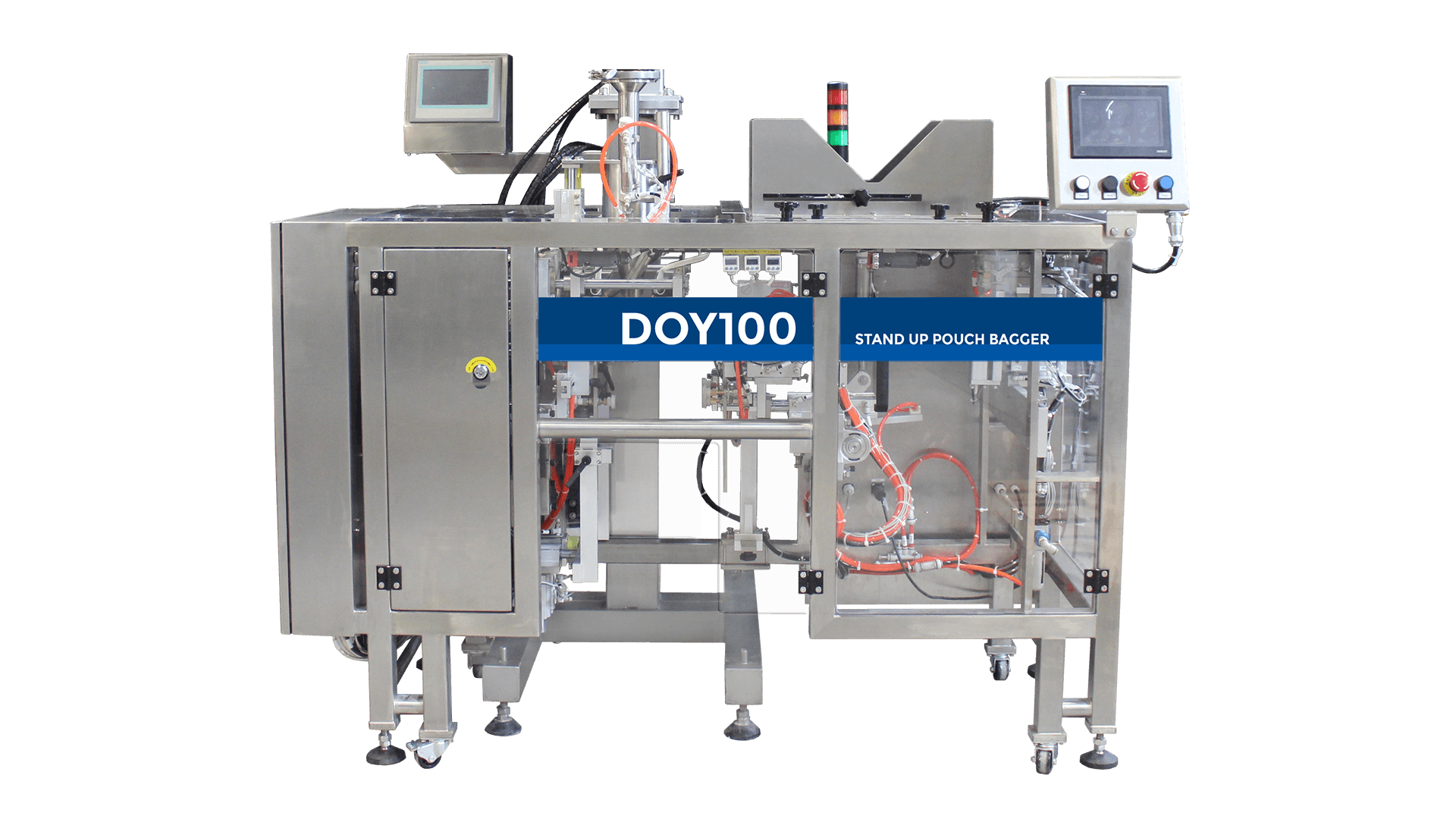

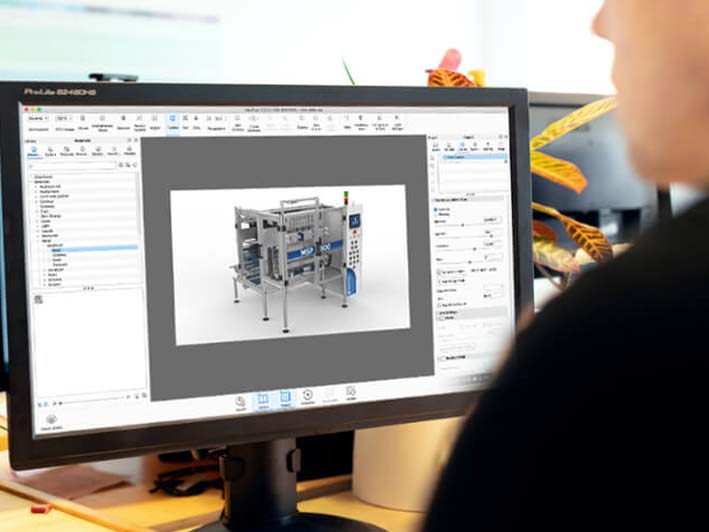

Stand up Pouch Bagger – Doy 100

minute max.

bag width

bag length

Mid Volume

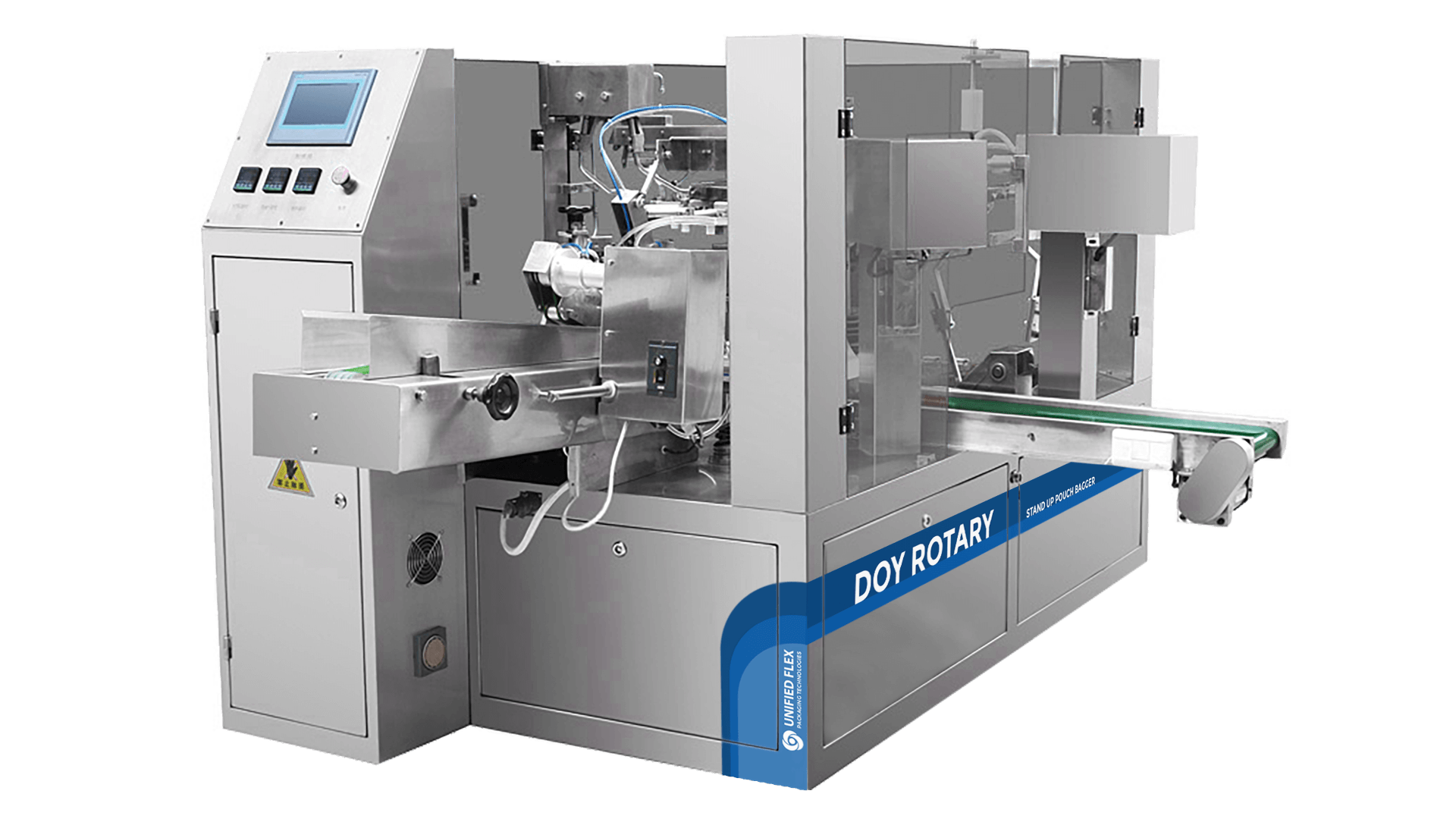

Stand up Pouch Bagger – Doy Rotary

min max.

bag width

bag length

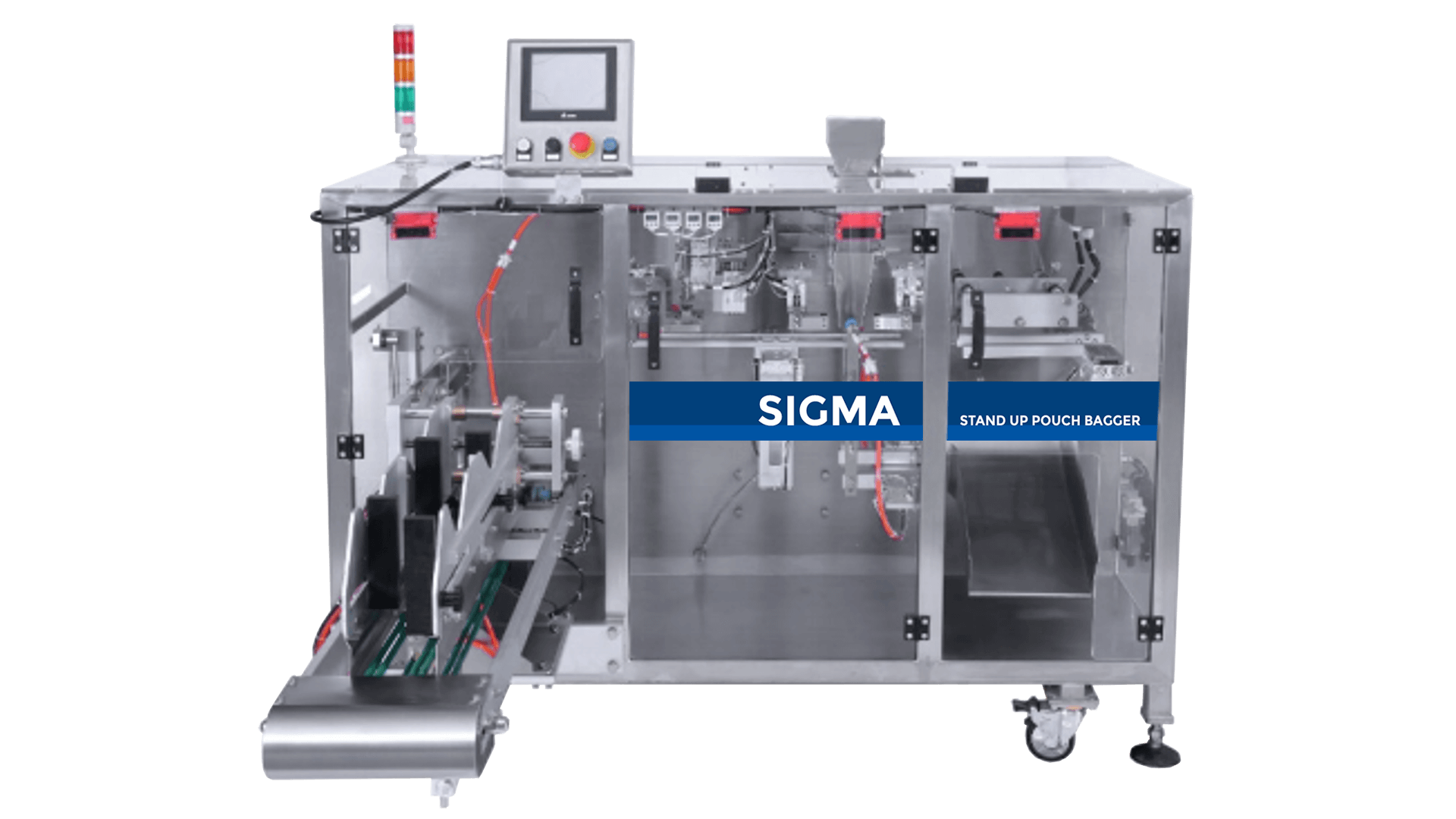

Stand up Pouch Bagger – Doy Sigma

minute max.

bag width

bag length

Bulk Volumes

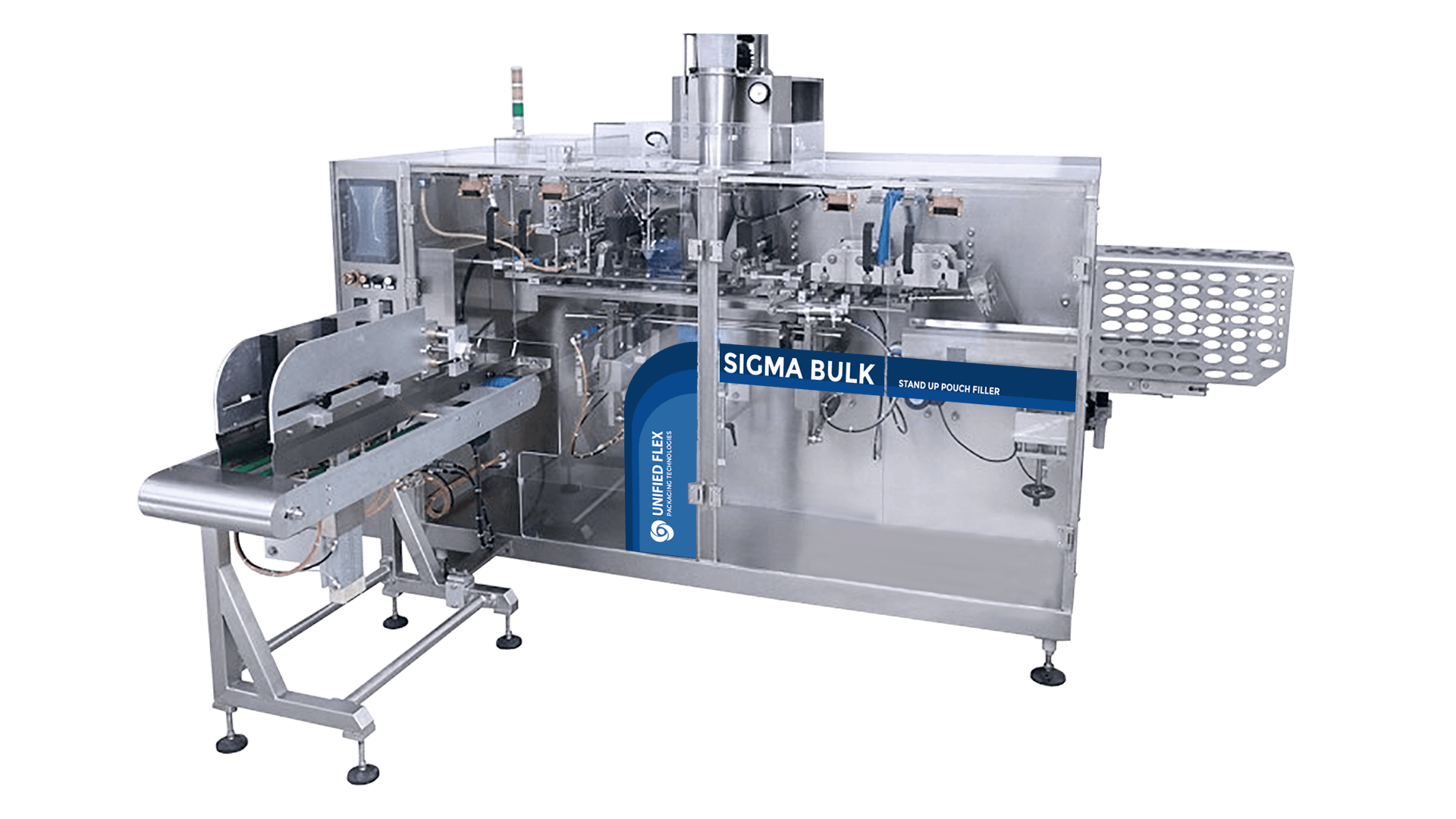

Stand up Pouch Bagger – Doy Sigma Bulk

minute max.

bag width

bag length

Frequently Asked Questions

What is a stand up pouch packaging machine?

A stand-up pouch packaging machine is a specialized device designed to form, fill, and seal stand-up pouches—flexible containers that can stand upright on their own. These pouches are widely used for packaging food, beverages, pet food, pharmaceuticals, and household products.

Key Features of Stand-Up Pouch Packaging Machines

Pouch Formation

The machine forms pouches from flat rolls of flexible materials such as plastic films, paper, or foil. To allow the pouch to stand upright, the bottom is typically gusseted or pre-formed.

Filling

Once the pouch is formed, the machine fills it with the desired product. It can handle solids, liquids, powders, or granules, depending on the application.

Sealing

After filling, the machine heat-seals the top of the pouch to maintain product freshness and prevent contamination.

Additional Features

Many stand-up pouch machines can integrate consumer-friendly enhancements, such as:

- Pour Spouts: Ideal for liquid products.

- Reclosable Zippers: Enhances freshness and convenience.

- Tear Notches: Allows for easy opening.

A stand-up pouch packaging machine is a specialized device designed to form, fill, and seal stand-up pouches—flexible containers that can stand upright on their own. These pouches are widely used for packaging food, beverages, pet food, pharmaceuticals, and household products.

Key Features of Stand-Up Pouch Packaging Machines

Pouch Formation

The machine forms pouches from flat rolls of flexible materials such as plastic films, paper, or foil. To allow the pouch to stand upright, the bottom is typically gusseted or pre-formed.

Filling

Once the pouch is formed, the machine fills it with the desired product. It can handle solids, liquids, powders, or granules, depending on the application.

Sealing

After filling, the machine heat-seals the top of the pouch to maintain product freshness and prevent contamination.

Additional Features

Many stand-up pouch machines can integrate consumer-friendly enhancements, such as:

- Pour Spouts: Ideal for liquid products.

- Reclosable Zippers: Enhances freshness and convenience.

- Tear Notches: Allows for easy opening.

Boost Your Packaging Efficiency with Unified Flex

For manufacturers seeking high-performance stand-up pouch packaging solutions, Unified Flex offers advanced machinery tailored to diverse production needs. Our equipment is designed to maximize efficiency and maintain the highest quality standards.

How does a stand-up pouch filling and sealing machine work?

A stand-up pouch filling and sealing machine automates the process of packaging products into flexible, self-standing pouches. These machines are widely used in beverages, nutraceuticals, and household products due to their efficiency and versatility.

Key Components and Process

Pouch Loading

Pre-made stand-up pouches are manually placed or automatically fed into the machine’s magazine. The system then picks and positions each pouch for the next steps.

Pouch Opening

The machine uses vacuum suction cups and, in some cases, mechanical grippers to open the pouches, ensuring proper alignment for filling.

Filling

The product whether liquid, powder, or solid is dispensed into the pouch using a filling system suited to the product type, such as:

- Auger fillers for powders

- Liquid pumps for beverages and sauces

- Volumetric fillers for granules and dry goods

Sealing

After filling, the machine heat-seals the top of the pouch, ensuring product freshness and contamination prevention.

Discharge

The sealed pouches are then discharged, and ready for labeling, storage, or distribution.

For businesses looking to streamline their packaging process, Unified Flex offers high-efficiency stand-up pouch filling and sealing machines designed for precision and reliability. Contact us today to find the perfect solution for your business!

What are the benefits of a stand-up pouch packing machine?

A stand-up pouch packing machine offers several advantages, making it an essential solution for efficient packaging.

Increased Production Speed: Automates filling and sealing, handling 15 + pouches per minute for higher efficiency.

Precise Filling & Reduced Waste: Uses advanced multi-head weighers, auger, or piston fillers to ensure accurate product dosing.

Improved Seal Quality & Shelf Life: Heat or ultrasonic sealing ensures airtight packaging and nitrogen flushing helps extend product freshness.

Versatile Packaging Options: Compatible with zippered, spouted, flat-bottom, and gusseted pouches for various industries.

Lower Labor Costs & Greater Consistency: Reduces manual work while ensuring uniform packaging quality.

Enhanced Product Presentation: Supports custom-printed pouches with glossy, matte, or transparent finishes to improve shelf appeal.

To find the perfect stand-up pouch packaging solution for your business, contact Unified Flex today!

What types of products are ideal for stand-up pouch packaging machines?

Stand-up pouch packaging machines are designed to package a diverse range of products, making them an ideal choice for industries that require efficient, flexible, and high-quality packaging solutions.

1. Food & Beverage

- Dry Foods: Snacks, nuts, chips, dried fruits, granola

- Powders: Coffee, protein powders, spices, flour

- Liquids & Semi-Liquids: Sauces, soups, salad dressings, baby food, and spouted beverages

- Frozen & Refrigerated Items: Frozen vegetables, shredded cheese

2. Pharmaceutical & Nutraceutical

- Powders & Supplements: Vitamin powders, collagen, herbal supplements

- Medical & OTC Products: Protein supplements, herbal remedies, and single-dose liquid supplements

3. Pet Food & Animal Nutrition

- Dry & Wet Pet Food: Kibble, treats, freeze-dried meals, and spouted pouches for liquid pet food

- Nutritional Supplements: Powdered and liquid pet vitamins

4. Household & Personal Care

- Detergents & Cleaning Agents: Liquid detergents, powdered cleaners, soap pods

- Cosmetics & Skincare: Lotions, facial masks, bath salts, shampoo refills

5. Industrial & Chemical

- Powdered & Granulated Chemicals: Fertilizers, detergents, adhesives

- Lubricants & Industrial Fluids: Household oils, cleaning solvents, liquid detergents

With the rising demand for stand-up pouch packaging, businesses need efficient and reliable solutions to maintain product quality and extend shelf life.

Find the Right Stand-Up Pouch Packaging Solution with Unified Flex

At Unified Flex, we provide high-performance stand-up pouch packaging machines tailored to various industries, including food, pet food, personal care, and industrial products.

Looking for the right stand-up pouch packaging solution? Get in touch now by clicking here!

Can Stand-Up Pouch Bagging machines handle pouches with resealable features like zippers?

Yes, stand-up pouch bagging machines are designed to handle pouches with resealable zippers, ensuring smooth operation throughout the packaging process.

These machines use mechanical grippers and guided tracks to open and hold the pouch in place, while zipper pre-closing mechanisms ensure proper alignment before final sealing. This guarantees a secure closure that maintains product integrity.

Suitable for snacks, coffee, pet food, personal care items, and more, zipper pouches help preserve freshness, prevent spills, and enhance convenience for consumers.

Unified Flex offers reliable stand-up pouch machines that efficiently handle zipper pouches along with other packaging features. Contact us today to find the right solution for your packaging needs!

What is the maximum pouch size that can be accommodated by Stand-Up Pouch Bagging machines?

The maximum pouch size a stand-up pouch bagging machine can handle depends on the model.

Unified Flex offers different machines with varying size capacities:

- Doy 100 can accommodate pouches up to 13 inches wide and 14 inches long.

- Doy Rotary supports larger pouches, handling up to 15.74 inches wide and 22.83 inches long.

- Doy Sigma is designed for pouches up to 10.23 inches wide and 13.77 inches long.

- Doy Sigma Bulk can handle pouches up to 16.14 inches (410 mm) wide and 27.55 inches (700 mm) long, making it suitable for snack foods, produce, grains, pet food, and chemicals.

For businesses requiring larger pouch sizes, the Doy Sigma Bulk and Doy Rotary models offer the highest capacity, ensuring efficient and reliable packaging for bulk products.

Contact us today to find the best stand-up pouch bagging machine for your business!

How do stand-up pouch machines ensure accurate filling and sealing?

Stand-up pouch machines integrate automation, smart sensors, and precision engineering to ensure accurate filling and secure sealing. These technologies help minimize waste, improve efficiency, and maintain consistent packaging quality across industries.

1. Precision Filling Technology

- Multihead Weighers, Auger, and Volumetric Fillers: Designed for accurate filling of powders, granules, and liquids, ensuring precise portioning.

- No-Pouch, No-Fill Sensors: Prevents dispensing if a pouch is missing or misaligned, avoiding product waste and mess.

- Vacuum Sensors for Pouch Opening: Ensures the pouch is fully open before filling, improving efficiency and reducing errors.

2. Smart Pouch Handling & Alignment

- 8-Station Rotary Indexing System: Guides pouches through each stage: opening, filling, settling, sealing, and dispensing.

- Strong Gripper Fingers & Suction Cups: Securely hold pouches during the process for consistent handling and alignment.

- Adjustable Suction Cup Mounts: Allow customization for different pouch sizes and materials.

3. Advanced Sealing Technology

- Temperature-Controlled Heat Sealing: Uses digital temperature controllers for a strong, airtight seal.

- Zipper Opening Function: Ensures proper zipper alignment and sealing for resealable pouches.

- Vacuum & Pneumatic Sealing Support: Enhances sealing reliability for various pouch materials and applications.

4. Automated Quality Control & Real-Time Adjustments

- Siemens PLC-Controlled Functionality: Ensures precise automation and process adjustments.

- Checkweighers & Vision Systems: Automatically verify pouch weight and seal integrity for consistent quality.

- Self-Diagnosing & Error Detection: Identifies inconsistencies and alerts operators, reducing downtime and improving efficiency.

By integrating these cutting-edge technologies, Unified Flex’s stand-up pouch machines ensure precise, reliable, and high-speed packaging for snacks, produce, liquids, coffee, pet food, and more.

Contact Unified Flex today to find the best stand-up pouch packaging solution for your business!

Are Stand-Up Pouch Bagging machines suitable for both food and non-food products?

Yes, stand-up pouch bagging machines are designed to handle both food and non-food products, making them a versatile and efficient packaging solution across various industries.

Food Applications

Snacks & Dry Foods: Chips, nuts, dried fruits, granola

Powders & Granules: Coffee, protein powders, spices, flour

Liquids & Semi-Liquids: Sauces, soups, baby food (spouted pouch system may be required for certain liquids)

Frozen & Refrigerated Items: Frozen vegetables, shredded cheese

Non-Food Applications

Pharmaceutical & Nutraceuticals: Vitamin powders, herbal supplements, medical products

Pet Food & Animal Nutrition: Dry and wet pet food, powdered and liquid supplements

Household & Personal Care: Detergents, soap pods, lotions, bath salts, shampoo refills

Industrial & Chemical Products: Fertilizers, powdered detergents, lubricants, adhesives (high-barrier films may be required for certain chemicals)

With advanced automation, precision sealing, and flexible pouch handling, stand-up pouch machines provide secure, high-quality packaging while preserving product freshness and extending shelf life.

Contact Unified Flex today to find the best stand-up pouch packaging solution for your business!

What features are available for stand-up pouch bagging machines?

Stand-up pouch bagging machines integrate automation, precision engineering, and smart sensors to ensure accurate filling, reliable sealing, and high-speed operation. These features enhance efficiency, reduce waste, and improve packaging consistency.

1. Pouch Handling & Automation

- Motorized Bag Feeding System: Ensures precise and consistent pouch movement for smooth operation.

- 8-Station Rotary Indexing System: Guides pouches through the opening, filling, settling, sealing, and dispensing stages.

- Vacuum Suction & Gripper Systems: Securely hold and open pouches for accurate filling.

- Bag Detection Sensors: Prevent filling if a pouch is missing or misaligned.

- Quick & Easy Bag Changeover: Adjustable settings allow for different pouch sizes.

2. Advanced Filling Systems

- Auger Fillers: Ideal for powders like spices, coffee, and protein powder.

- Combination Scales: Provide accurate weight measurement for granules, snacks, and nuts.

- Piston Fillers: Best for liquids and semi-liquids, such as sauces and creams.

- Volumetric Cup Fillers: Suitable for dry products like grains and cereals.

- Continuous Pumps: Designed for high-viscosity liquids like syrups and detergents.

3. Sealing & Closure Features

- Digital Temperature-Controlled Heat Sealing: Uses precise heat control to ensure airtight and tamper-proof seals.

- Zipper Opening Mechanism: Ensures proper alignment and sealing of resealable pouches.

- Optional Spout & Cap Integration: Suitable for liquid products requiring resealable pour spouts.

4. Additional Customization & Quality Control

- Nitrogen Flush System: Removes oxygen before sealing to extend product shelf life.

- No-Bag, No-Fill Technology: Stops filling if no pouch is detected, preventing product waste.

- Vacuum Sensors: Ensure pouches are properly opened before filling.

- Lot & Date Code Printers: Essential for compliance and traceability.

Find the Right Pouch Packaging Solution with Unified Flex

Unified Flex offers stand-up pouch bagging machines with these advanced features, ensuring high-speed, reliable, and efficient packaging for food, beverages, pet food, pharmaceuticals, and more.

Need the right pouch packaging machine? Contact Unified Flex today!

Smart Stand-Up Pouch Machines Built for Demanding Operations

Let’s be honest—packaging can make or break a product.

In the era of rapid production demands, every second counts—and so does every pouch. If your packaging line slows down, everything else follows: production targets, delivery timelines, customer satisfaction, and ultimately, your bottom line.

Be it gourmet coffee, plant-based protein, or household cleaning products, you can’t afford inefficiencies, frequent stoppages, or inconsistent output. Speed, consistency, and flexibility aren’t optional—they’re the standard.

That’s where Unified Flex’s Stand Up Pouch Packaging Machine makes the difference.

Built for busy production lines, our machines use smart technology to fill pouches accurately, seal them tightly, and keep things moving. The result? Strong, reliable packaging that protects your product and looks great on shelves.

What Is a Stand-Up Pouch Machine?

You’ve seen them—those sleek, self-standing pouches sitting neatly on store shelves, catching your eye with bright branding and clean finishes. That’s stand-up pouch packaging, and behind every one of those is a machine working quietly behind the scenes, making it all happen.

A stand up pouch packing machine is exactly what it sounds like—it forms, fills, and seals flexible pouches that stand upright on their own. They’re perfect for everything from dry snacks and liquids to powders, gels, and granules. Bonus? They look great on shelves and are super convenient for consumers.

Did you know?

Stand-up pouches use up to 60% less plastic than rigid packaging.

Common Packaging Challenges Faced by Businesses

Let’s talk about what packaging leaders are dealing with on the ground:

- Frequent downtime due to mechanical issues or poor pouch handling

- Inaccurate fills and leaky seals leading to costly product loss

- Inability to scale without adding more labor

- Manual packaging bottlenecks impacting output

- Inflexible machines that can’t handle varying pouch sizes or materials

Unified Flex engineers have designed solutions specifically to eliminate these bottlenecks.

Question to consider:

How much time and money could you save if just one of these issues disappeared from your production floor?

Why Stand-Up Pouches Are Taking Over the Market

Let’s be real—stand-up pouches are more than just trendy. They’re practical, eco-conscious, and cost-effective. That’s why engineers, managers, and business leaders across industries are making the switch.

Here’s what makes them a game-changer:

- Portable and space-saving

- Less material waste compared to rigid containers

- Options like zippers, spouts, and tear notches

- Excellent for branding and shelf appeal

- Compatible with a wide range of product types

Fact: The global stand-up pouch market is expected to reach $36 billion by 2027.

Let’s Solve Your Packaging Challenges

Still packaging by hand or struggling with an outdated machine? Unified Flex’s custom stand-up pouch packaging machine helps you:

- Increase throughput

- Maintain consistent quality

- Reduce operational downtime

- Improve ROI on packaging automation

- Future-proof your production line

Our team will help you assess your current workflow, recommend the best-fit model, and support seamless integration.

Three High-Performance Machines to Suit Your Needs

We offer a variety of models built to support different production volumes, bag sizes, and product types.

Low Volume Stand-Up Pouch Bagging Machine

Designed for small-scale production or startup operations, the Doy 100 offers dependable performance for packaging stand-up pouches efficiently with a compact footprint.

Ideal for:

- Small-batch packaging operations

- Startups and pilot production lines

- Limited space environments

- Test runs or seasonal product lines

- Manual or semi-automated production upgrades

Low Volume Stand-Up Pouch Bagging Machine Model:

Model | Max Speed | Max Width | Max Length |

Doy 100 | 17 bags/min | 13″ | 14″ |

Mid Volume Stand-Up Pouch Bagging Machines

These mid-volume models strike the perfect balance between speed and flexibility. Depending on your needs, continuous rotary motion or servo-driven accuracy, both machines are ideal for growing operations.

Ideal for:

- Medium-scale production facilities

- Companies scaling up packaging operations

- A wide range of food and non-food applications

- Contract packagers needing versatility

- Consistent and repeatable pouch filling

Mid Volume Stand-Up Pouch Bagging Machine Models:

Model | Max Speed | Max Width | Max Length |

Doy Rotary | 40 bags/min | 15.74″ | 22.83″ |

Doy Sigma | 20 bags/min | 10.23″ | 13.77″ |

Bulk Volume Stand-Up Pouch Bagging Machine

Built for industrial-scale production, the Doy Sigma Bulk handles large-format pouches with ease and precision. It’s engineered for speed, reliability, and performance in demanding environments.

Ideal for:

- Bulk or family-sized product packaging

- High-volume production lines

- Pet food, lawn and garden, or bulk snack applications

- Industrial packaging operations

- Large-scale contract manufacturing

Bulk Volume Stand-Up Pouch Bagging Machine Model:

Model | Max Speed | Max Width | Max Length |

Doy Sigma Bulk | 15 bags/min | 16.14″ | 27.55″ |

What Can You Package with Stand-Up Pouch Bagging Machines?

Big or small, dry or liquid—our stand-up pouch machines handle a world of products with speed, accuracy, and reliability.

Food Applications

- Snacks & Dry Foods

- Powders & Granules

- Liquids & Semi-Liquids

- Frozen & Refrigerated Items

Non-Food Applications

- Pharmaceutical & Nutraceuticals

- Pet Food & Animal Nutrition

- Household & Personal Care

- Industrial & Chemical Products

Ready to Upgrade Your Packaging Line?

No matter if you’re launching a new product line, growing your capacity, or transitioning from older systems, Unified Flex delivers innovative, consistent, and customizable pouch packaging systems that align with your goals.

Contact us today to schedule a free consultation and decide which stand up pouch filling machine is best suited for your production line.