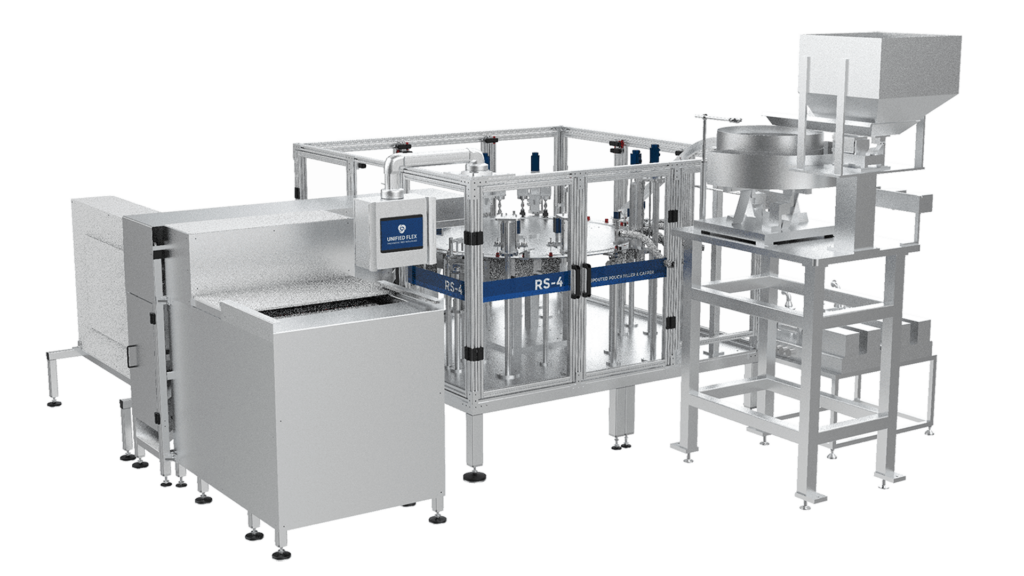

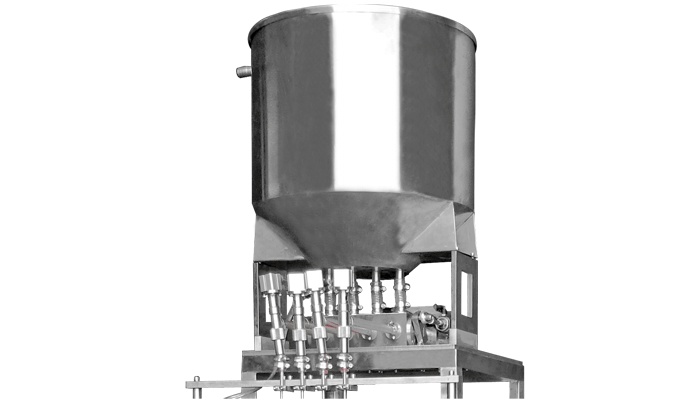

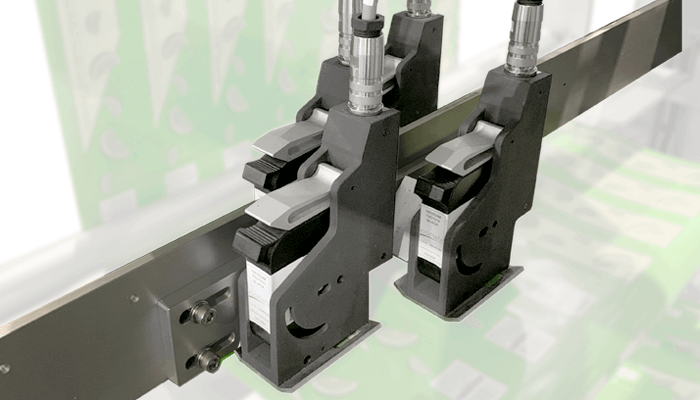

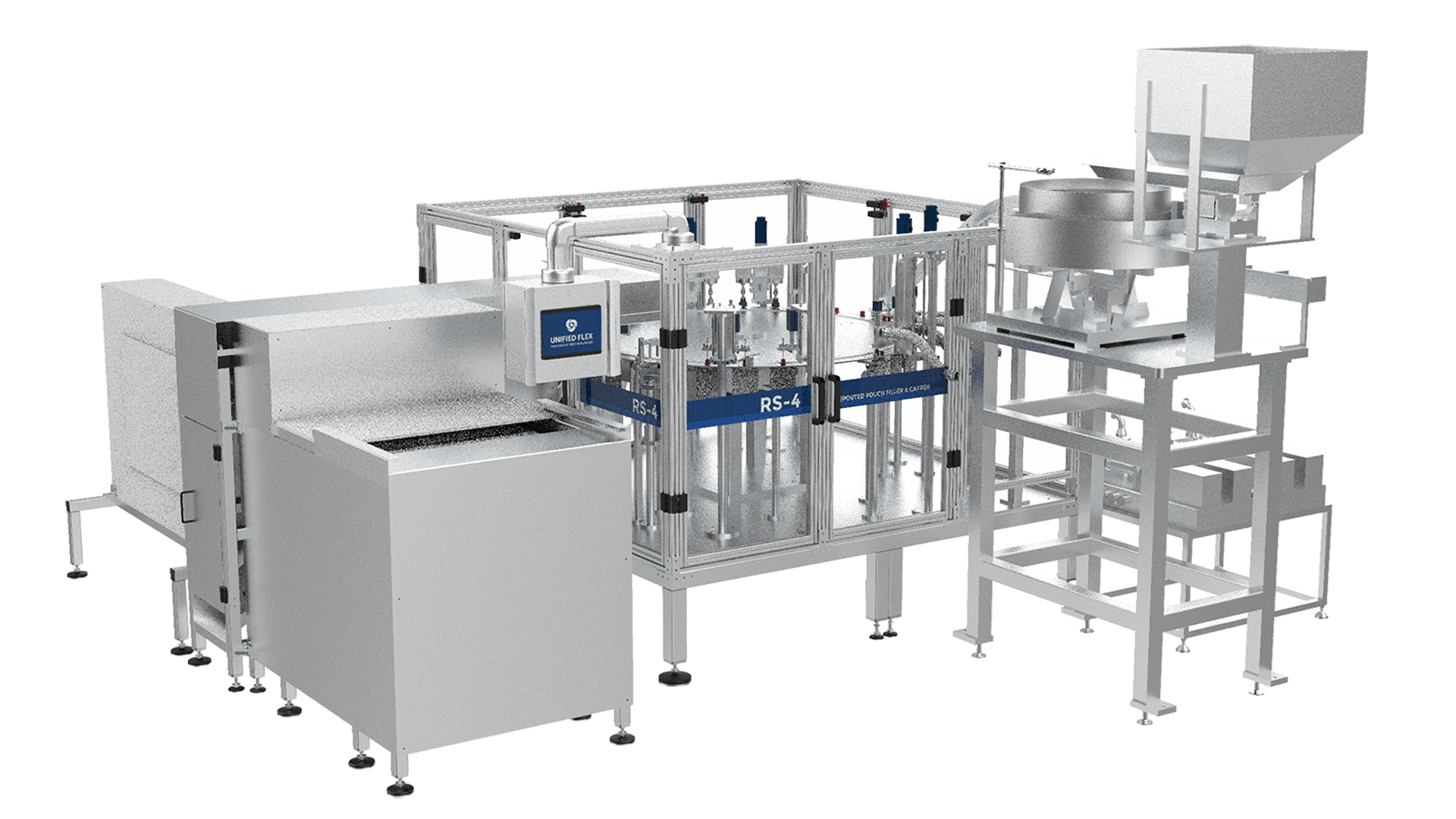

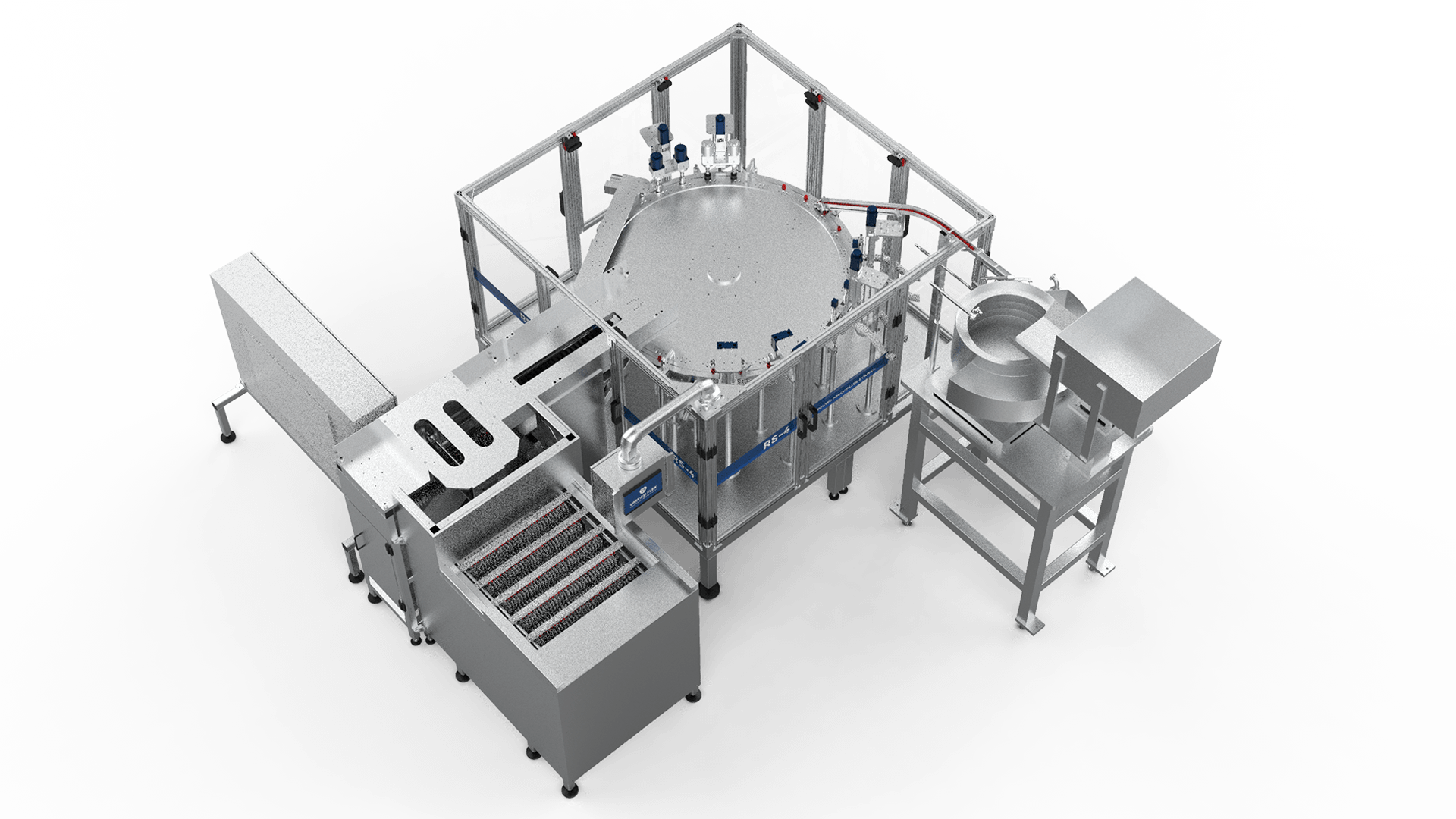

Spouted Pouch Filler & Capper RS-4 can process four premade pouches at once based on a four-filler setup. This rotary pouch filling & capping machine can pack viscous & free flowing liquids even those containing particulates. Ideal for various liquid fill applications like edible oils, sauces, drinks, juices, alternate dairy and more. Non-edible applications include synthetic oils, liquid soaps, paint, shampoo, lotions, liquid detergents and more. Easy integration with piston fillers makes this machine a top choice for complete liquid packaging solutions.

To download the brochure or to receive the floor plans for the Spouted Pouch Filler & Capper RS-4, visit the ‘More Resources’ section below.