Every scoop of plant-based protein powder represents a promise, clean ingredients, conscious production, and care for the planet. But even the best formulation needs a packaging process that protects it. When pouches tear, powders clump, or freshness fades, it’s not just product loss; it’s credibility lost.

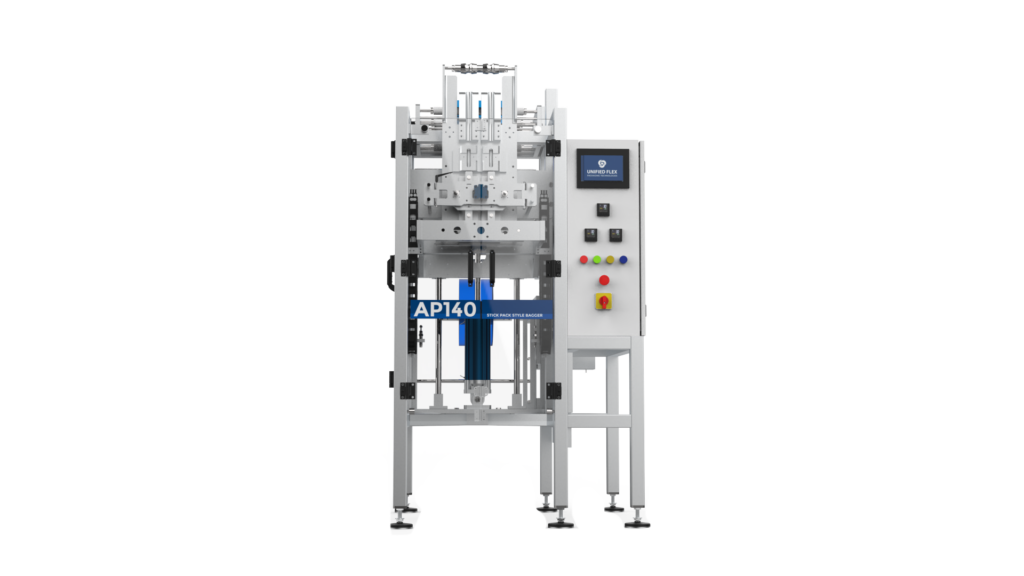

That’s why we built the AP-140 Protein Powder Packing Machine, a flexible packaging system designed for modern nutrition brands. It doesn’t just pack powder, it safeguards your values. With engineering precision, custom-fit design, and sustainability at its core, the AP-140 helps you deliver every serving exactly as intended: clean, consistent, and trustworthy.

You know your blends, the density of pea protein, the flow of hemp, and the aeration of rice-based powders. You’ve perfected your recipe; now it’s time for packaging that keeps up.

At Unified Flex, we tailor every protein powder packing machine to your specific product behavior. Our engineers design systems that fill smoothly, seal tightly, and preserve freshness under all conditions. We don’t sell equipment; we craft solutions that reflect your brand’s precision and reliability.

Because when your product stands for wellness, your packaging should stand for trust.

Flexible packaging is reshaping how health-conscious consumers experience nutrition. Pre-measured sachets, resealable pouches, and sample packs make your product more portable, more hygienic, and easier to trust.

The AP-140 protein powder packing machine automates this process: forming, filling, sealing, and cutting each pack to perfection, all in one continuous, efficient cycle.

The AP-140 Protein Powder Packing Machine is precision in motion, designed to package plant-based powders with care, speed, and consistency. Compact, reliable, and easy to maintain, it’s the trusted choice for brands that value control as much as creativity.

Sustainability isn’t a checkbox; it’s a reflection of your identity. We help you package with purpose by integrating eco-friendly materials, energy-efficient systems, and precision film control into every solution.

With sustainable vegan protein powder packaging, you reduce waste, cut material use, and give your customers the assurance that your care for the planet runs deeper than words.

The AP-140 proves that sustainability and scalability can coexist beautifully, one perfectly sealed pouch at a time.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Protein powder packaging demands tight control over sealing precision, product flow, and environmental variables. Fine, hygroscopic powders like pea or hemp protein tend to cling and dust during filling, which can compromise seal integrity. An effective packaging system must maintain stable temperature, dwell time, and sealing pressure, supported by consistent film tracking and contamination-free sealing zones. Machines with servo or pneumatic motion control, stainless steel contact parts, and integration with auger fillers are best suited to deliver clean, repeatable results at scale.

In protein powder packaging, flexible formats such as sachets, stick packs, and pillow bags offer the best balance between product protection, sustainability, and operational efficiency. Each serves a distinct role: sachets deliver precise portioning with minimal oxygen exposure, stick packs optimize film usage and high-speed output, and pillow bags provide strength and stability for larger retail or foodservice formats.

To achieve consistent quality, these formats are produced on vertical form fill seal (VFFS) systems specifically engineered for protein powder packaging. Such machines must maintain precise film tension, stable sealing temperatures, and clean filling environments to prevent dust contamination or seal failure. When paired with auger or volumetric fillers, these systems ensure accurate dosing, reliable seals, and a streamlined packaging process designed for long-term performance and sustainability.

A reliable plant-based protein powder packaging machine must deliver precision, consistency, and process stability, especially when dealing with fine or hygroscopic materials. Key performance factors include accurate dosing, contamination-free sealing, and stable film control under varying production conditions. Machines with servo or pneumatic motion systems maintain tight control over sealing pressure and temperature, ensuring every bag is properly sealed without product loss. Integration flexibility with auger or volumetric fillers is also essential, enabling smooth transitions between different powder types or packaging formats. Beyond performance, manufacturers should prioritize equipment built for ease of maintenance, long-term reliability, and compatibility with recyclable films, ensuring both operational efficiency and sustainability over time.