CUSTOM-ENGINEERED MACHINERY

CUSTOM-ENGINEERED MACHINERY

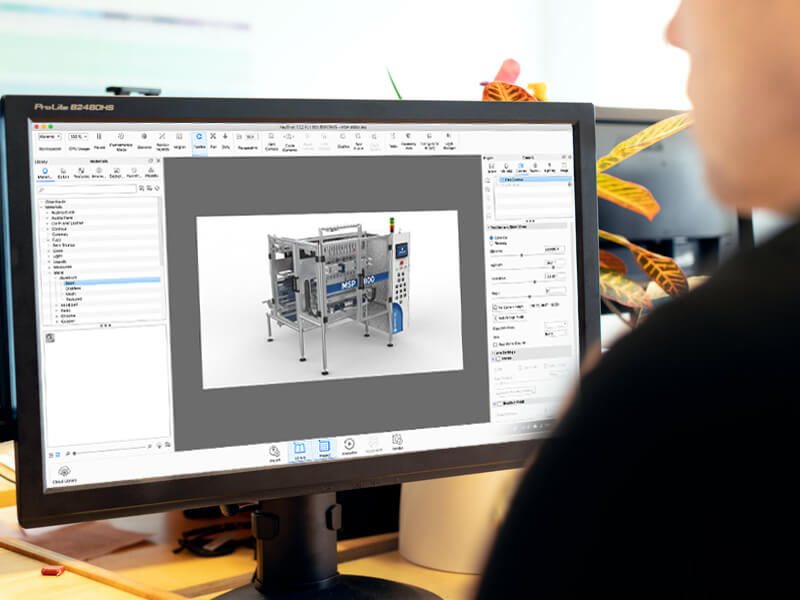

Custom Packaging Machines, Configuration, and Engineering Solutions

As a leading provider of equipment engineering solutions, we take great pride in offering custom packaging machines designed to meet your unique production needs. Our engineering scope is not limited to standard offerings of turnkey systems, we are open to tackling one-off customized challenges that do not qualify as traditional methods.

The experienced team of packaging and engineering experts at Unified Flex works closely with you to understand production processes and challenges. This foundational work enables us to create a one-of-a-kind packaging solution that delivers optimal performance and efficiency.

Custom Packaging Machines

Sometimes good isn’t good enough. Innovative solutions are necessary in today’s competitive manufacturing environment to help businesses meet their goals.

At Unified Flex Packaging Technologies, we have a proven track record of bringing fresh ideas and custom machines to the packaging world. Our research and development process and expert engineers allow us to tackle even the toughest packaging challenges.

Have a unique packaging need? Let’s discuss how custom-engineered packaging machinery can help you achieve your goals.

Packaging Machine Configuration

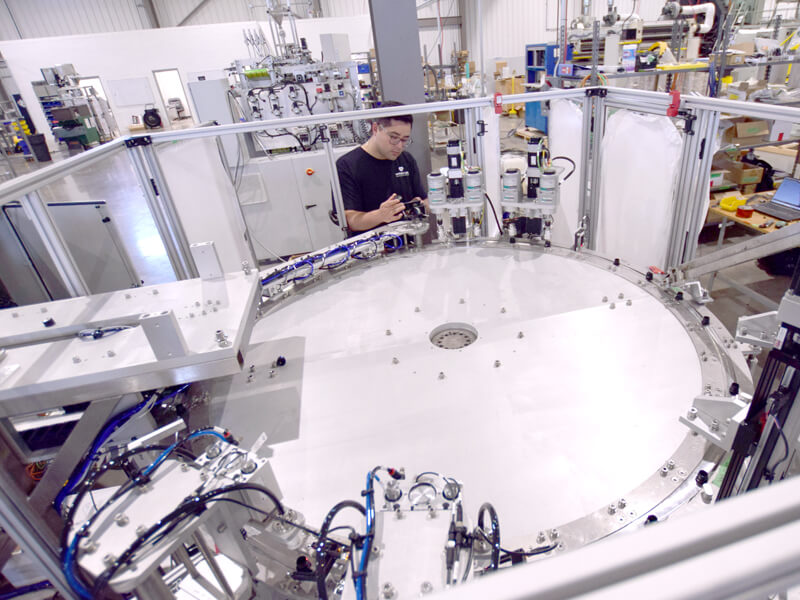

Whether you are adding another packaging line or need to integrate a new piece of equipment with your existing machinery, Unified Flex can help configure packaging systems that save space and work with your current floor plan.

Height limitation and lack of floor space are often concerns in cramped manufacturing facilities. We can configure packaging machines to take up the smallest footprint possible or accommodate low ceiling height while still performing as well, if not better, than larger or taller packaging equipment.

Want to maximize efficiency and space? Let’s talk about how we can configure your packaging equipment to meet your goals.

Our Design and Engineering Process: What Makes Unified Flex’s Customized Packaging Machinery Special

When standard packaging equipment won’t do, our team gets to work. Our research process, design & engineering expertise, and understanding of the industry allow us to hone in on the perfect equipment solutions for our customers. As we are developing new machinery and customizing solutions, we adhere to the following standards to ensure our customers get the best possible flexible packaging machinery solution.

Attention to Detail

We aim to get a solid understanding of the product and your branding and marketing objectives, so we can contribute with our expertise to ensure that the project is successful with respect to being marketable, efficient, and economical. We bring valuable hands-on experience to ensure the packaging style, material, and packaging equipment are aligned.

Application experience of the supplier

It is important for the supplier to have prior experience in a relevant packaging application. The length of time a supplier has been in business for is no measure of how well-equipped the supplier is to solve the packaging challenge. Packaging Technology is changing at a rapid pace. New motors, materials, and controllers have been introduced over the last decade. Today, machines are more efficient, economical, and capable than they were 20 years ago. Hence a supplier who has been in business for 30, 60 or 90 years is not a true measure that the solution offered by them is going to be the best in terms of efficiency and economics. In fact, it must be ensured that such a solution is not outdated, and it will be fit to work for the next 30 years.

Turnkey Systems

Not all equipment suppliers provide Turnkey Systems. Turnkey means all machines involved in the packaging process are supplied by the same equipment manufacturer. The advantage of buying a turnkey system is that you don’t have to allocate resources to ensure all the machines are well integrated. A feeding conveyor would have communication with a filling machine, the conveyor will only feed the filler only when it needs more product. Similarly, the bagging machine will be in two-way communication with the filling machine. Requesting for product only when it is ready with a qualified bag/pouch and once the bag or pouch is sealed, it will ask for more product from the filling machine. Also, it’s important to ensure that all machines fit together mechanically, allowing the product to flow smoothly throughout the packaging process. Another advantage of a turnkey system is that you don’t have to coordinate between 3 or 4 vendors. It saves time and human errors.

Simple Design & Engineering

The best design feature, a manufacturer can offer is simplicity. Whether configuring an existing machine or developing customized packaging equipment, we focus on simple and functional design that’s easy to service, maintain, set up, and use.

Strength & Durability

In addition to being simple and functional, our machines have strong construction. The components used in the assembly are robust, high-quality, and durable. We use electrical parts like motors, programmable logic controllers, and human-machine interface from top brands like Siemens, Rockwell, and Omron that offer the longest possible service life and are critical to the good operation of the equipment.

ease of use

A simple, functional, and strong machine design results in a pleasant user experience. It makes the machine easy to set up and easy to use. Our equipment offers ease of use in terms of the following features:

- Time to switch between 1 SKU to the other especially if the bag size is much different

- Ease of splicing a new roll of film on the machine

- Quick and easy access to the most commonly used features of the machine

- Ease of setting up a new packaging job on the machine

- Ability to store and retrieve recipes for various jobs on the machine

- The ability of the machine to easily adapt to a wide variety of packaging material

- The ability of the machine to be able to easily switch between different packaging styles

Easy to Clean

All product contact parts of the equipment are easily accessible for cleaning to prevent contamination.

Integration with the Manufacturing Process

Packaging systems should seamlessly integrate with the manufacturing process. We help develop alignment between packaging and manufacturing. We focus on solutions to prevent damage and deformation during the packaging process and contingency plans if the packaging equipment should go down.

Floor Layout of Equipment

As the packaging system supplier, we can provide a floor layout of the entire system to help you maximize machinery efficiency and avoid potential conflicts with other equipment, roof height, or other space restrictions.