The Quiet Evolution of Beans, Rice, and Pasta Packaging

Packaging dry staples like beans, rice, and pasta demands precision. This article explores how balanced film engineering, proven process control, and machine integration deliver measurable reliability, from film performance to consistent output, in modern flexible packaging systems.

How Rice, Beans, and Pasta Packaging Machines Are Powering a New Era for Dry Goods

Packaging pasta, beans, and rice demands accuracy and adaptability. This article explores how modern pasta packaging machines combine servo precision, film control, and modular design to deliver consistent seals, faster changeovers, and scalable performance across every production scale, from compact automation to high-speed industrial systems.

How Eco-Friendly Packaging Machines for Pasta, Beans, and Rice Are Changing the Future of Dry Goods

Sustainability in dry-goods packaging is about more than recyclable films. Explore how eco-friendly packaging machines for pasta, beans, and rice use servo control, film efficiency, and modular design to cut waste, save energy, and extend equipment life — proving that the smartest way to go green is through precision.

The Three Pressures Reshaping Cosmetic Packaging and Why Sachets Are Leading the Response

Cosmetic packaging is under pressure from three directions: complex formulations, faster operations, and sustainability demands. This blog explores how those challenges are transforming packaging from an aesthetic choice into a precision process — and how sachets, supported by automation and film innovation, have become the most adaptable, efficient response. Read the blog.

From Serums to Creams: How a Cosmetic Sachet Packaging Machine Ensures Perfect Packaging Every Time

Creating single-use sachets for cosmetics sounds simple until you’re managing foaming serums, dense creams, and strict hygiene demands. Precision and consistency are non-negotiable. This blog explores the real challenges behind cosmetic sachet packaging and how the MSB-406 brings control, cleanliness, and reliability to every fill and seal.

From Challenge to Control: Achieving Sustainable Cosmetic Packaging with the MSB-406

Sustainable cosmetic packaging depends on more than materials. The MSB-406 brings process efficiency to the forefront, combining precision motion control, reliable sealing, and easy maintenance to help brands meet sustainability goals through better engineering.

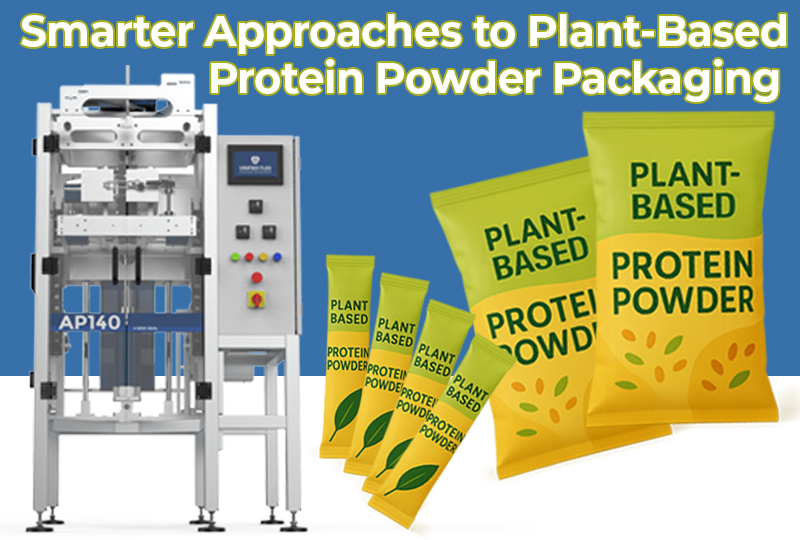

From Film to Format: Rethinking Plant-Based Protein Powder Packaging

Plant-based protein powders bring unique packaging challenges, from moisture sensitivity to sustainability demands. This article explores how the right film structure, format, and process control come together to maintain quality and consistency in every pack.

Designed for Real-World Results: The Protein Powder Packaging Machine That Delivers

Plant-based powders don’t play by the rules; they demand precision, control, and consistency. Discover how Unified Flex’s AP-140 turns fine, moisture-sensitive protein powders into shelf-stable, perfectly sealed pouches through real-world performance and reliable design.

Smarter Packaging for a Greener Future: How the AP-140 Is Powering Plant-Based Protein Packaging

The shift toward cleaner nutrition is transforming how brands approach packaging. For plant based protein powder in sustainable packaging, the real challenge isn’t choosing eco-friendly materials — it’s mastering the engineering behind them. From sealing sensitive powders to reducing waste and energy use, smarter systems are proving that sustainability isn’t a claim, it’s a process. Discover how precision engineering is driving a greener future for modern nutrition brands.

In Bulk Food Packaging, Reliability Lives in the Bag

Reliability in bulk food packaging is built into the bag. Explore how pillow bag geometry, barrier films, and sealing consistency create durable, efficient, and sustainable packaging that withstands pressure, vibration, and storage, proving that the most dependable packaging designs are often the simplest and most precisely engineered.