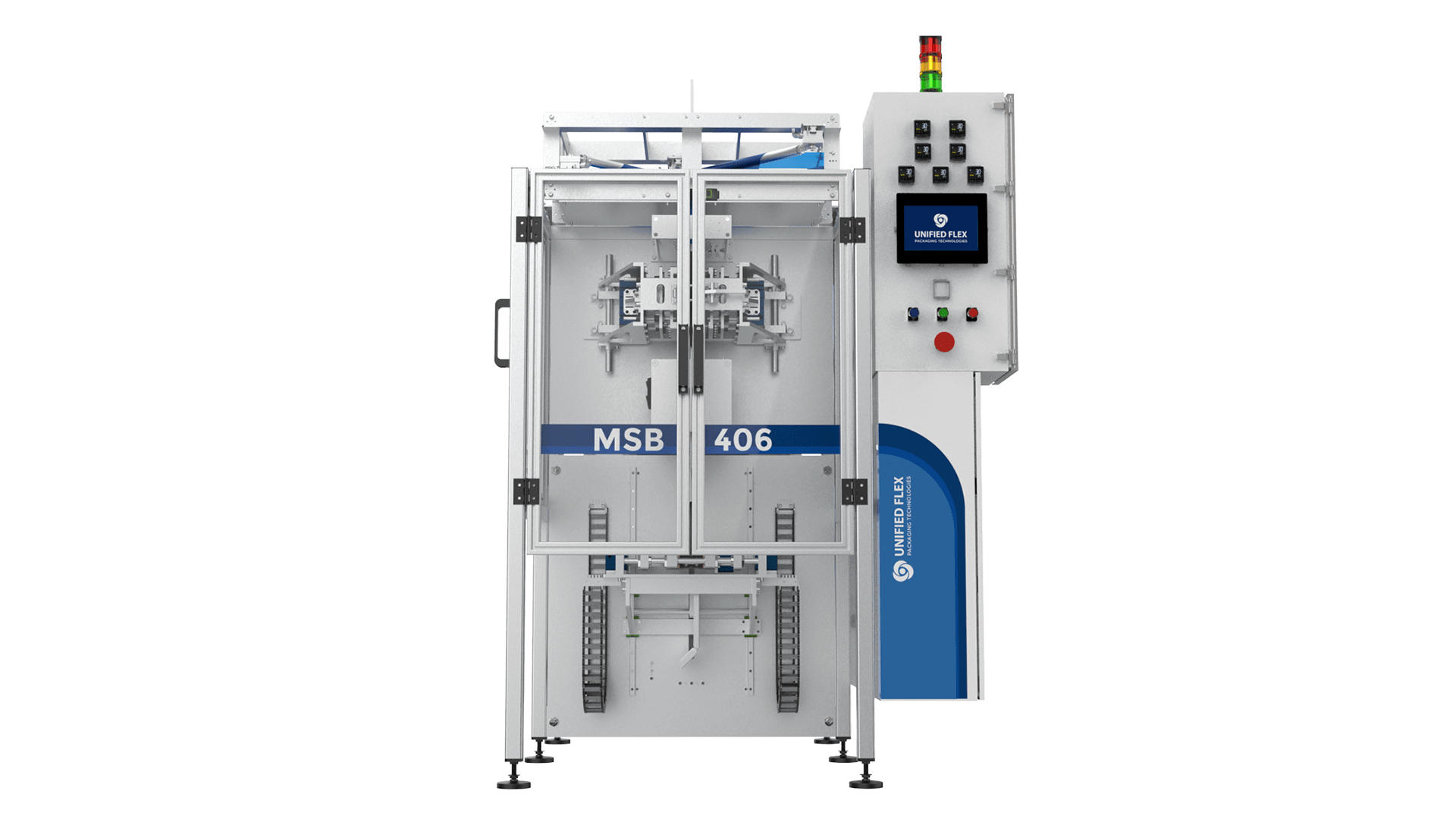

The 4 Lane Popsicle Sachet Bagger excels in producing popsicles with precision and efficiency, offering both 3 sided and 4 sided seal bags or sachets. Ideal for the booming beverage industry, this advanced bagging machine accommodates long sachet packages up to 12 inches in length and a maximum web width of 16 inches. Operating at speeds of up to 50 cycles per minute, this machine can deliver an impressive output of up to 200 sachets or freeze pops per minute, depending on product viscosity and sachet dimensions. With its focus on consistent package quality and minimal downtime, the 4 lane Popsicle Sachet Bagger is the ultimate solution for your production needs. See all markets.

To download the brochure or to receive the floor plans for the 4 Lane Popsicle Sachet Bagger, visit the ‘More Resources’ section below.