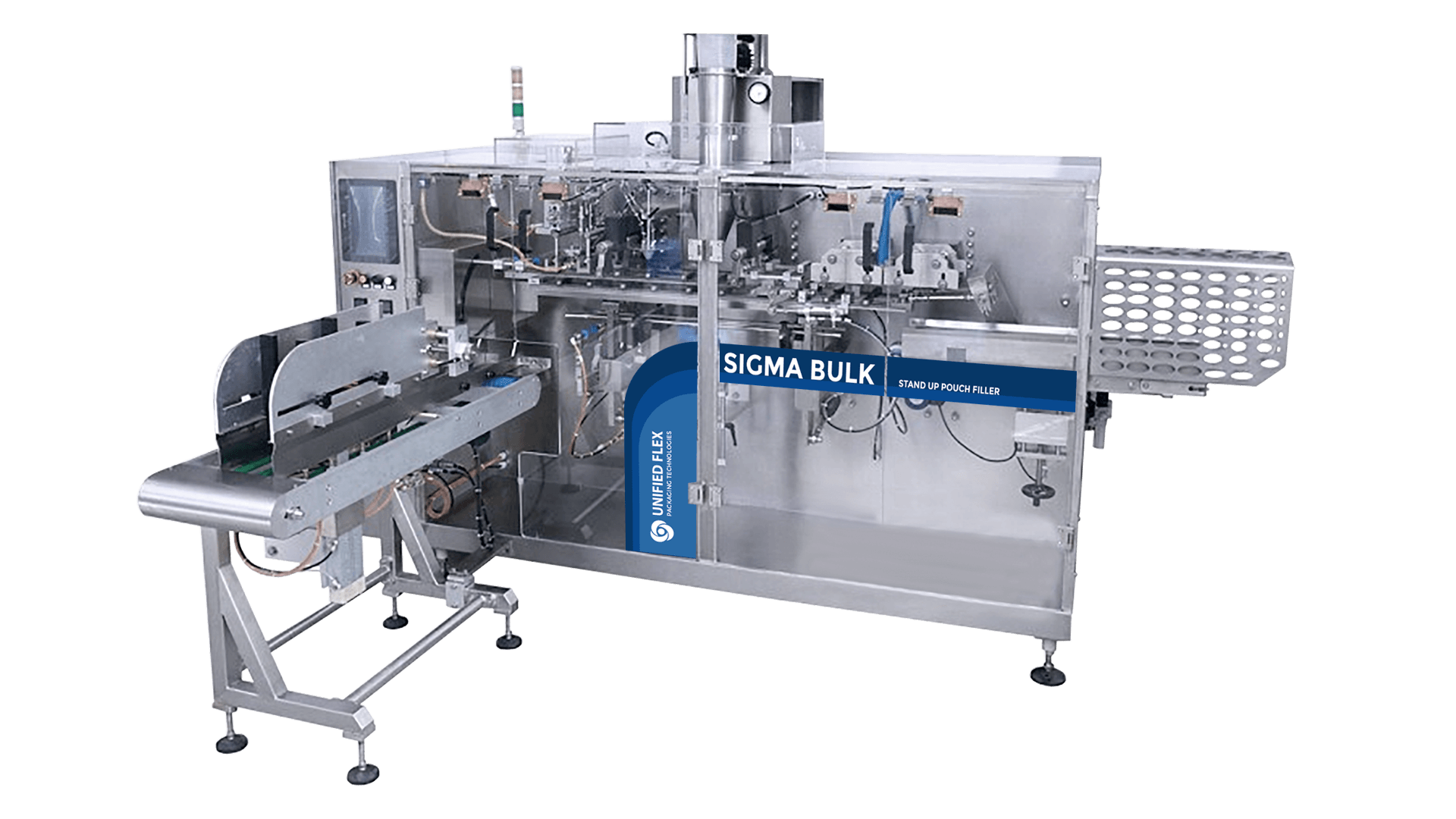

The Stand Up Pouch Bagger – Doy Sigma Bulk is a preformed pouch packaging machine designed for bulk fill applications of medium to high production volumes. It can pack Doy Stand-Up Pouches or box pouches with an optional zipper. This machine runs a servo motor mechanism for the smooth flow of pouches in a linear path. A convenient belt-driven pouch loading area allows for a rotary arm to pick up the pouches. There are two primary stations. On the first station, pouches are flexed and opened to receive the product from a dosing machine. On the second station, pouches are then sealed and transitioned out of the machine. Bag size changeovers are easy and quick. A wide range of optional features are available for this machine making it compatible with snack food, produce, grains, pet food, chemicals, and more. See all markets.

To download the brochure or to receive the floor plans for the Stand up Pouch Bagger – Doy Sigma Bulk, visit the ‘More Resources’ section below.