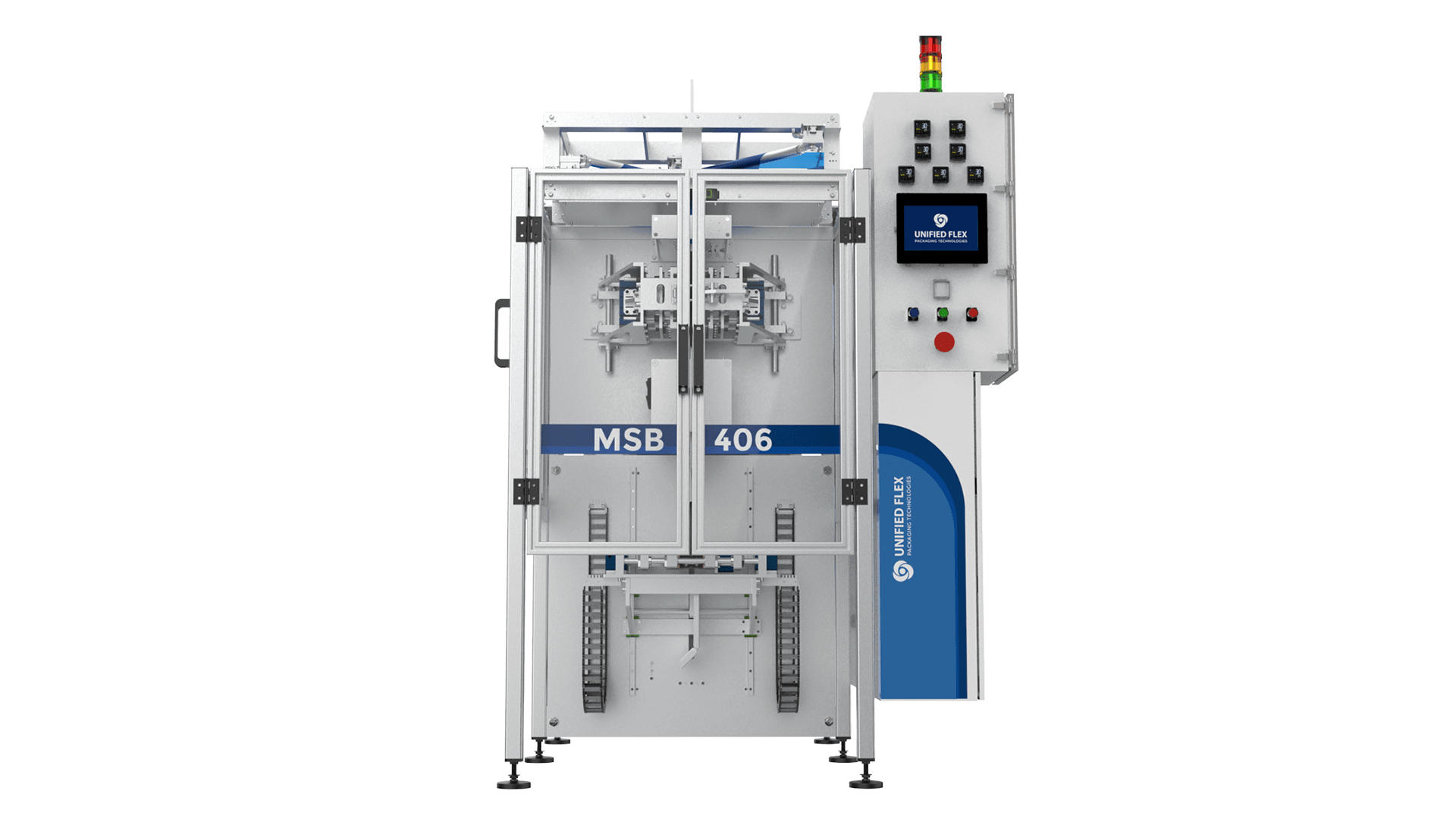

The Multilane Sachet Bagger – MSB 406mm is designed to be a modular and flexible automatic vertical form fill seal machine (VFFS) with a clean and simple design. Ease of use, ease of maintenance, and smooth operation are the main features of this machine. Robust and precise assembly makes this machine an ideal choice for packaging sachets of various sizes. The Multilane Sachet Bagger – MSB 406mm can accommodate up to 10 lanes to form sachet pouches. It is customized for Auger Fillers (Powders), Piston Fillers (Liquids), or Volumetric Fillers (Granular). This sachet bagging machine can be used for packaging a wide variety of products like powders, particulate materials, coffee, drink mixes, liquids or gels and more. See all markets.

To download the brochure or to receive the floor plans for the Multilane Sachet Bagger – MSB 406mm, visit the ‘More Resources’ section below.