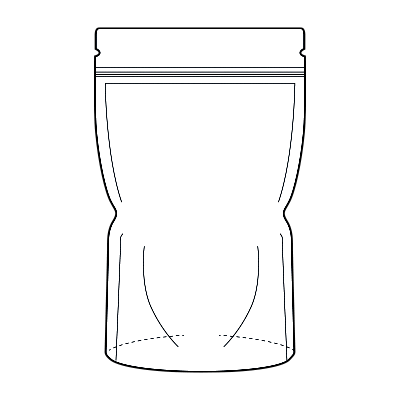

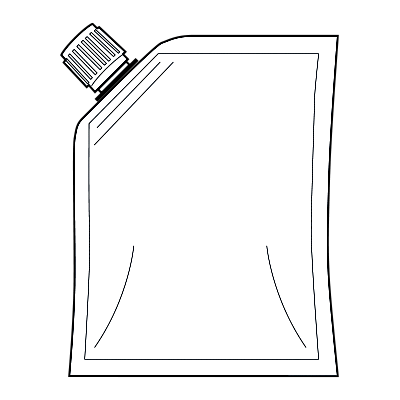

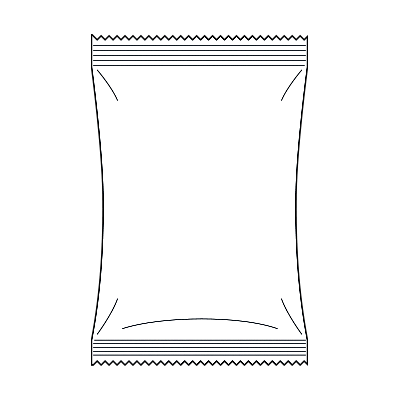

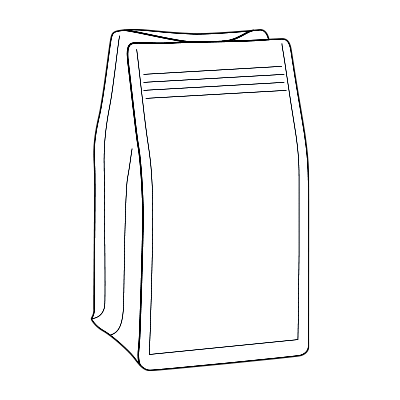

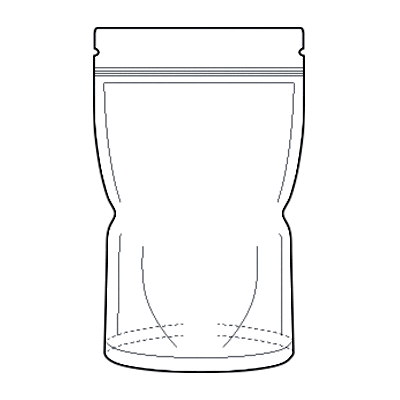

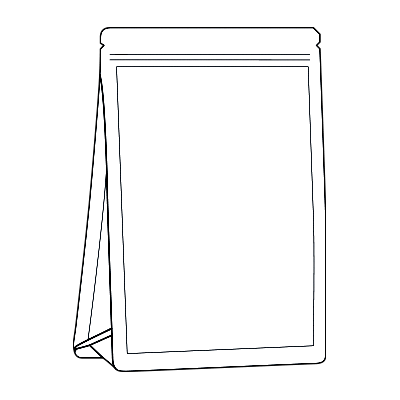

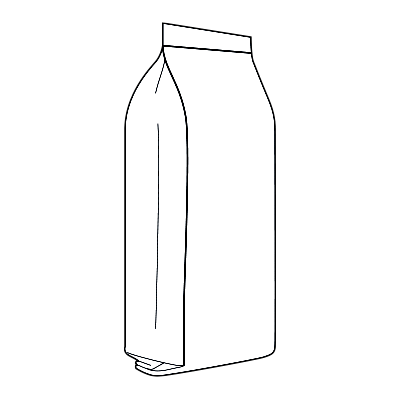

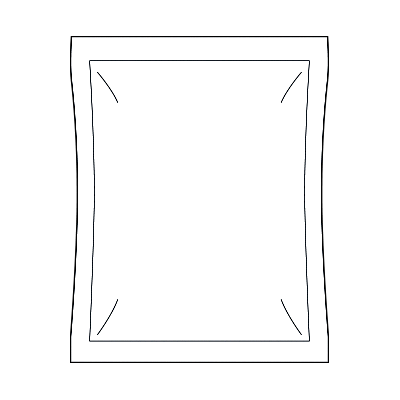

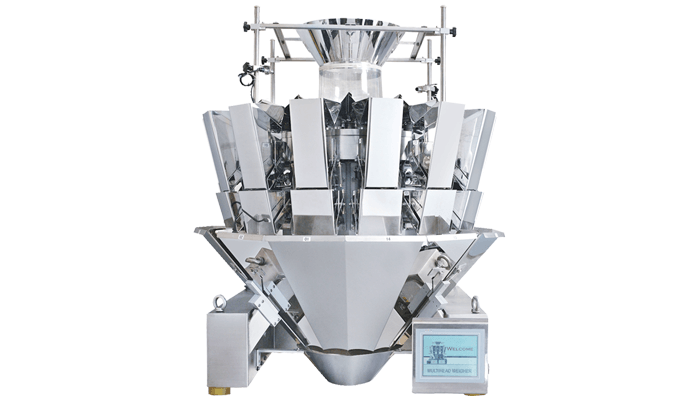

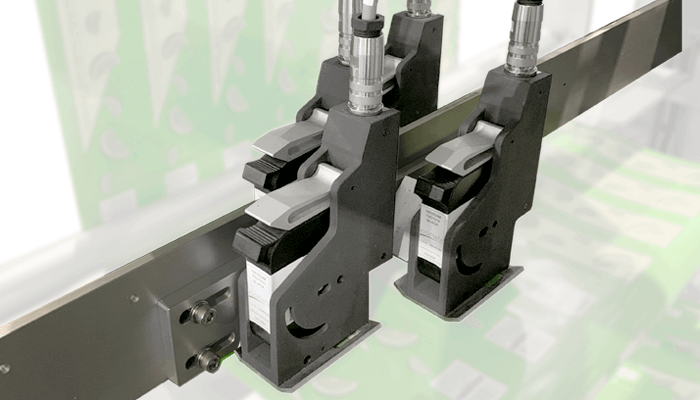

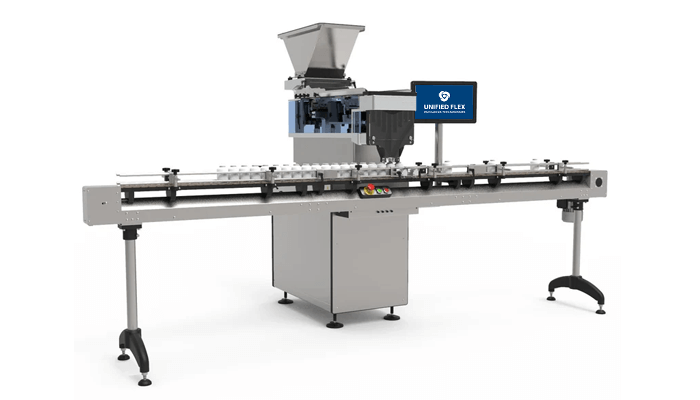

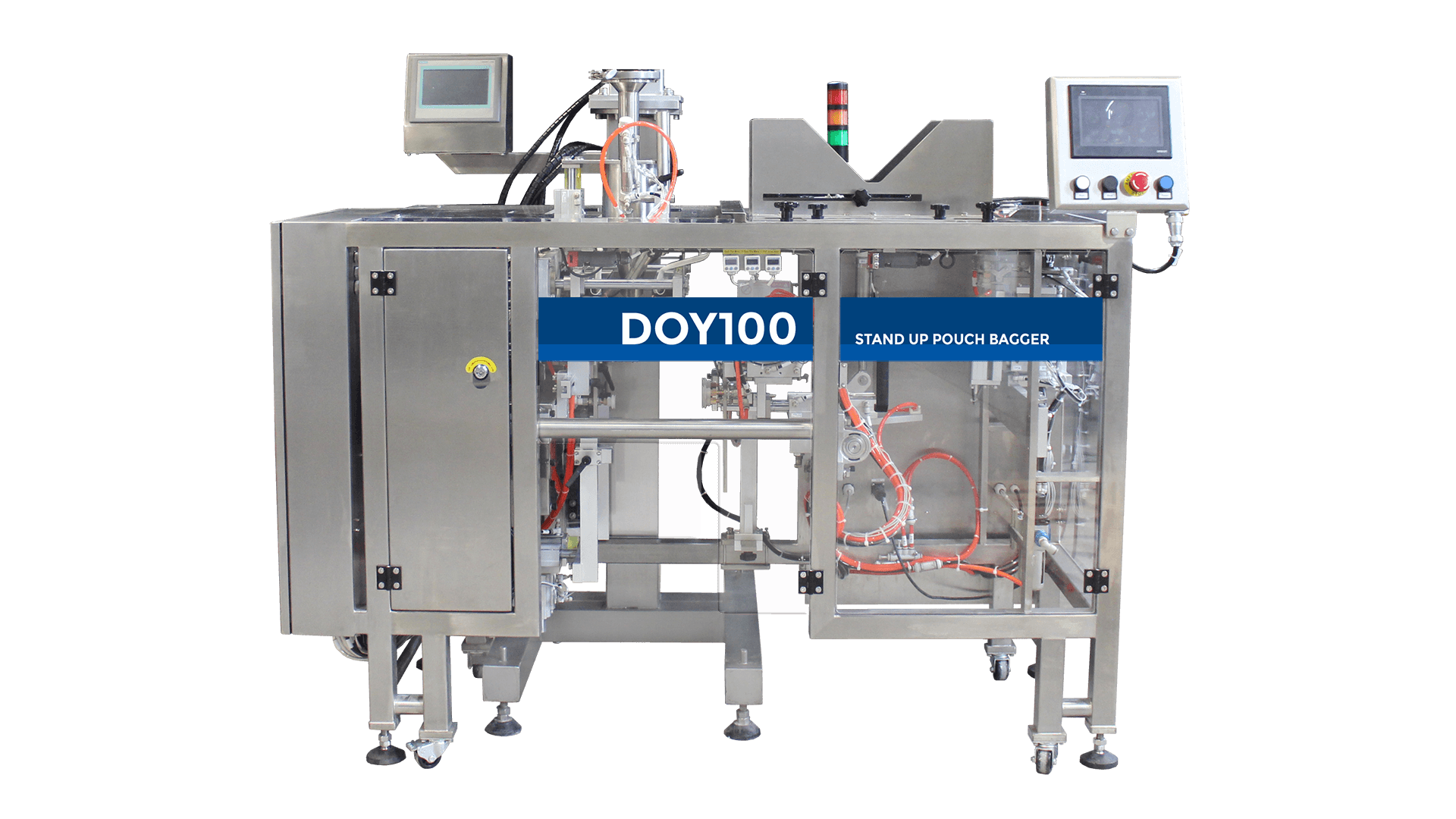

Our entry-level preformed pouch packaging machine is ideal for businesses with low to medium-production needs. Designed for efficiency, this versatile machine automatically picks, opens, fills, and seals a variety of preformed pouches, including doy rim style bags, pillow bags, and box pouches. From snacks and produce to liquids and coffee, this adaptable equipment handles multiple products with ease. Quick and simple bag size adjustments minimize downtime, while a range of optional features can be customized to meet specific packaging requirements.

To download the brochure or to receive the floor plans for the Stand up Pouch Bagger – Doy 100, visit the ‘More Resources’ section below.