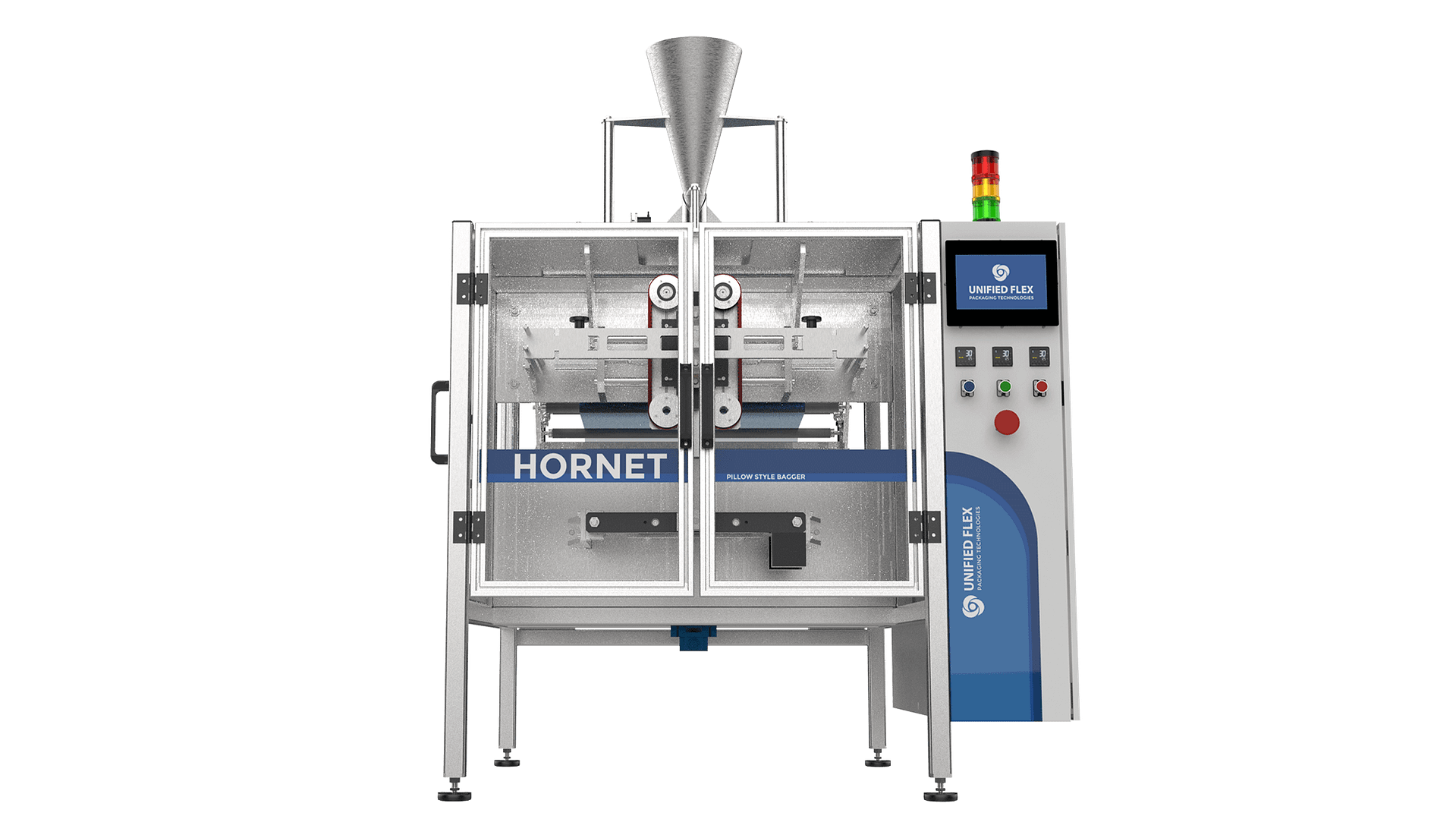

The VFFS Vertobagger Hornet is a vertical form fill seal machine designed with a clean and simple design. Ease of use, ease of maintenance, and smooth operation are the main features of this machine. Robust and precise assembly makes this machine a strong competitor in the industry. This bagging machine can be used for packaging a wide variety of products like snacks, coffee, liquids, produce, cheese, bakery, soups, pet food, and more. See all markets.

To download the brochure or to receive the floor plans for the VFFS Vertobagger Hornet, visit the ‘More Resources’ section below.