Stick Pack Machines

Stick Pack Machines

Unique Packaging Solutions for Single-Serve, Portable Products

Stick Pack Machines by Unified Flex can easily and quickly package your granular, liquid, or powder product into convenient, portable packaging ideal for today’s on-the-go consumers.

Our packaging machines are available with 1 to 16 lanes and offer an output of 40-800 stick packs per minute. These machines can package stick packs of various sizes with different seal and tear notch options. They’re ideal for packaging powders, coffee, drink mixes, liquids, gels, and more.

Stick Packs Per Minute

No. of lanes

Maximum Web Width

Maximum Cycles Per Min

Auto Pouch Bagger AP-140 Stick Pack

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 300mm

minute max.

stick pack width

stick pack length

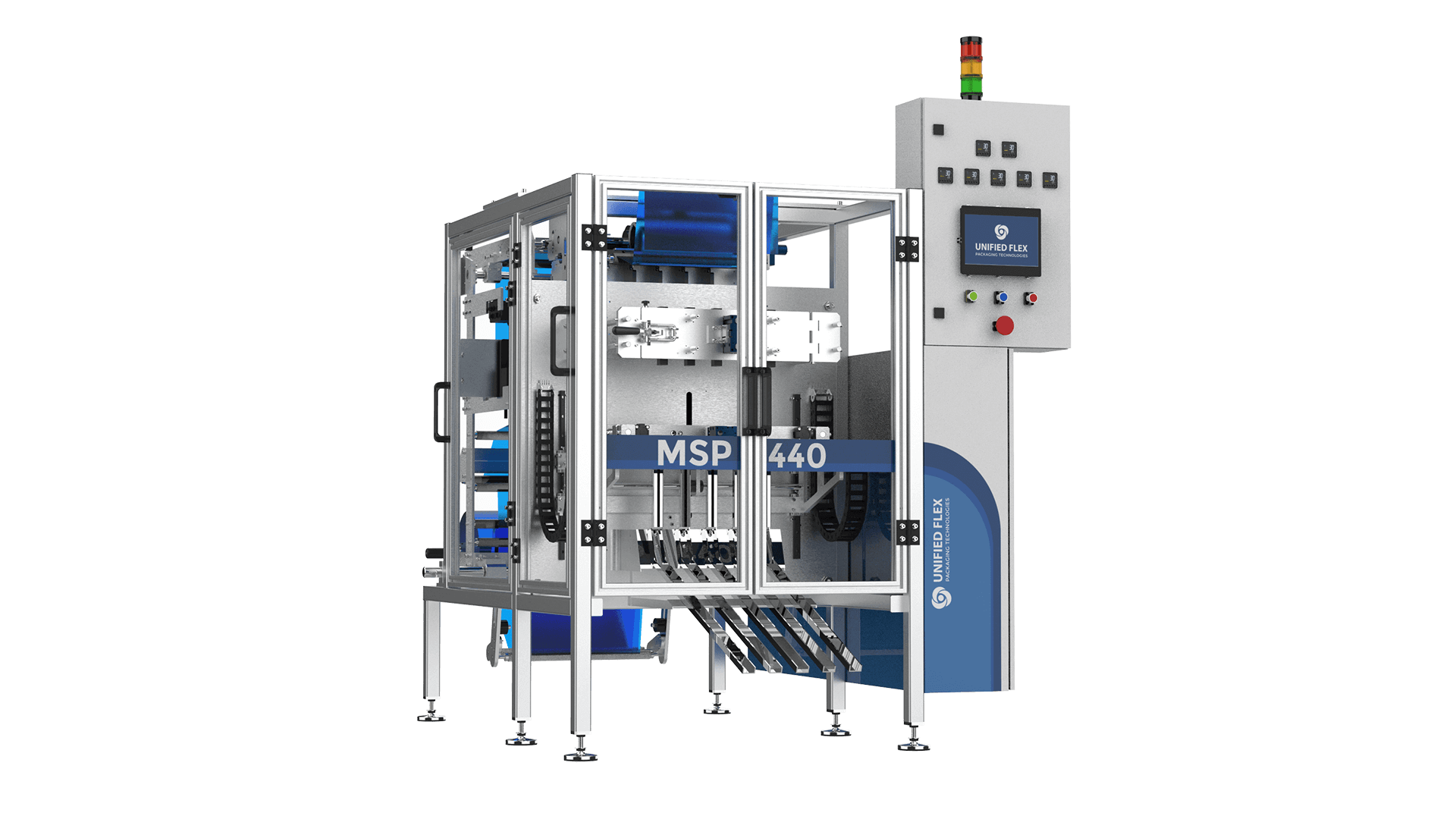

Multilane Stick Pack – MSP 440mm

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 800mm

minute max.

stick pack width

stick pack length

Frequently Asked Questions

What is a stick pack machine?

Stick pack machines are specialized packaging systems designed to efficiently produce slim, elongated pouches, commonly known as stick packs. These machines are widely used for packaging powders, granules, liquids, and gels, making them ideal for single-serving applications in industries such as food, pharmaceuticals, nutraceuticals, coffee, cosmetics, and more.

Available in both single-lane and multi-lane configurations, stick pack machines offer flexibility based on production needs; single-lane models are ideal for smaller-scale operations, while multi-lane machines significantly increase output for high-volume production. Their compact design minimizes material usage, reducing waste and making them a cost-effective solution compared to traditional stick pack packaging.

Additionally, they offer various customization options, such as different seal patterns, tear notches, and cut types, to accommodate specific branding and functionality needs. Advanced automation and precision filling systems ensure consistent product dosing, secure sealing, and high-speed operation, providing manufacturers with a reliable and scalable packaging solution.

Looking for a high-performance stick pack machine? Contact us today to explore our customized solutions designed to enhance your packaging efficiency!

What are the benefits of stick pack machines?

Stick pack machines provide an efficient, cost-effective, and precise packaging solution for single-serve, elongated pouches used in industries such as beverages, nutraceuticals, cosmetics, and more. These machines are designed to optimize production speed, material usage, and product protection while ensuring convenience and accuracy in packaging.

Here are the key benefits of using stick pack machines:

Cost-Effective: Stick pack machines use less packaging material, reducing production costs and minimizing waste.

Efficient Space Utilization: Stick pack machines are designed to efficiently produce compact packaging, optimizing storage and transportation, and reducing material usage.

High-Speed Production: These machines automate the filling and sealing process, allowing for rapid, high-volume packaging with minimal manual labor.

Versatile Applications: Stick pack machines can handle a variety of products, including powders, granules, liquids, and gels, making them suitable for multiple industries.

Precision Sealing for Product Freshness: Stick pack machines use heat or ultrasonic sealing to create airtight, moisture-resistant packaging, preserving product quality and extending shelf life.

Customization & Branding: These machines allow for high-quality printing and customizable designs, improving product presentation and brand recognition.

Eco-Friendly: Stick packs use less material compared to other packaging formats, reducing waste and supporting sustainable packaging solutions.

For more information on how stick pack machines can benefit your production process, contact Unified Flex today!

What industries commonly use stick pack machines for their packaging needs?

Stick pack machines are versatile packaging solutions utilized across various industries due to their efficiency and convenience. Key sectors that commonly employ stick pack machines include:

Food and Beverage: Products such as instant coffee, sugar, spices, sauces, and condiments are often packaged in stick packs for portion control and portability.

Pharmaceuticals and Nutraceuticals: Single-dose medications, vitamins, and health supplements are packaged in stick packs to ensure accurate dosing and ease of use.

Cosmetics and Personal Care: Items like creams, lotions, shampoos, and gels are packaged in stick packs for single-use convenience and hygiene.

The adaptability of stick pack machines to handle various product types makes them a valuable asset in these industries, enhancing both production efficiency and consumer satisfaction.

At Unified Flex Packaging Technologies, we specialize in providing advanced stick pack machines tailored to your specific needs. Our machines are designed for versatility and efficiency, capable of handling various products including powders, liquids, and gels. With options ranging from 1 to 16 lanes, our equipment can produce between 40 to 800 stick packs per minute, accommodating both small and large-scale production requirements.

To learn more about how our stick pack machines can enhance your packaging operations, contact us now.

What benefits do stick pack machines provide to the pharmaceutical, food, and cosmetics manufacturing processes?

Stick pack machines offer several advantages to manufacturers in the pharmaceutical, food, and cosmetics industries:

Pharmaceutical Industry

- Precise Dosage Control: Stick pack machines ensure accurate portioning of medications, which is crucial for patient safety and treatment efficacy.

- Enhanced Product Stability: The airtight sealing of stick packs protects pharmaceutical products from environmental factors like moisture and air, thereby maintaining their potency and extending shelf life.

Food Industry

- Portion Control and Convenience: Stick packs offer single-serving portions, making them ideal for on-the-go consumption and helping consumers manage portion sizes effectively.

- Extended Shelf Life: The packaging provides a barrier against contaminants and environmental factors, preserving the freshness and quality of food products.

Cosmetics Industry

- Hygienic Single-Use Packaging: For products like creams, lotions, and serums, stick packs offer a sanitary single-use option, reducing the risk of contamination and ensuring product integrity.

- Portability and Convenience: The compact design of stick packs makes them easy for consumers to carry, catering to the demand for travel-friendly and on-the-go cosmetic products.

These industry-specific benefits highlight how stick pack machines can enhance product quality, consumer satisfaction, and operational efficiency across the pharmaceutical, food, and cosmetics sectors.

Are Stick Pack Machines machines compatible with eco-friendly or compostable materials?

Yes, Stick Pack Machines can be adapted to work with eco-friendly material, but certain adjustments may be necessary for optimal performance.

At Unified Flex, our Stick Pack Machines are designed to work with single-layer sustainable films, including:

Compostable Films – PLA, PHA, and biodegradable paper-based materials.

Recyclable Films – Mono-material polyethylene (PE) and polypropylene (PP).

Since eco-friendly films may have different sealing properties and flexibility compared to traditional plastics, adjustments such as low-temperature heat sealing, optimized tension control, and enhanced film handling may be required.

Before transitioning to sustainable packaging, we recommend testing materials for compatibility and ensuring compliance with industry standards such as ASTM D6400, EN 13432, and FDA/EU food safety regulations.

At Unified Flex, we specialize in custom Stick Pack Machines engineered for single-layer sustainable films. If you’re looking to transition to sustainable packaging, contact us now.

What sealing options are available to prevent leaks in stick packs?

Ensuring effective sealing in stick pack packaging is crucial to prevent leaks, maintain product integrity, and extend shelf life. Various sealing options are available, each suited to different product types and packaging requirements:

1. Heat Sealing

This common method involves applying heat and pressure to thermoplastic materials, causing them to fuse. Heat sealing is widely used for its reliability and strong seal formation.

2. Ultrasonic Sealing

Employing high-frequency ultrasonic vibrations, this method generates heat through friction, sealing the materials. Ultrasonic sealing is precise and energy-efficient, suitable for various applications.

3. Easy-Open Seal Options

To enhance consumer convenience, easy-open features can be incorporated into stick packs:

- Tear Notches: Pre-cut areas that allow consumers to open the package without additional tools.

- Perforated Seals: Dotted lines that facilitate easy tearing along a designated path.

These features improve user experience by simplifying access to the product.

At Unified Flex, we provide advanced stick pack machines designed to deliver precise, efficient, and customizable sealing solutions. Whether you need heat sealing, ultrasonic sealing, or easy-open features, we offer tailored options to meet your packaging needs. Contact us today to find the best sealing solution for your products.

How do machines handle tear notches, perforations, or easy-open features?

In stick pack packaging, incorporating tear notches, perforations, and easy-open features enhances consumer convenience by facilitating effortless access to the product. Manufacturers achieve these features through specific machine configurations and optional attachments:

1. Tear Notches

Tear notches are pre-cut areas on the packaging that allow consumers to open the package easily without additional tools. These notches are integrated into the packaging process using punching tools or cutting dies that create precise indentations along the desired opening path. This design ensures consistent and easy opening, improving user experience.

2. Perforations

Perforations consist of a series of small holes or slits that weaken the packaging material, allowing for easy tearing along a specific line. In stick pack machines, perforations are created using mechanical perforation rollers or laser systems, which precisely cut or punch holes into the film without compromising the integrity of the package. This method ensures a smooth and controlled tearing experience.

3. Easy-Open Features

Easy-open features, such as tear notches and micro perforations, enhance consumer convenience by simplifying product access. These features are integrated into the packaging process using specialized cutting and forming tools that shape the package and create the desired opening mechanisms. This ensures that consumers can effortlessly access the product, improving usability and satisfaction.

By incorporating these features, manufacturers can create functional and user-friendly packaging that meets consumer expectations for convenience and ease of use.

Unified Flex provides stick pack machines designed to integrate these easy-open solutions with precision and efficiency. Contact us today to learn more!

How many lanes can a stick pack machine run at the same time?

Stick pack machines are designed to operate multiple lanes simultaneously, enhancing production efficiency and throughput. The number of lanes a machine can handle varies based on its design and intended application.

For instance, Unified Flex offers the Multilane Stick Pack – MSP 300mm, which can operate up to 6 lanes, producing up to 300 stick packs per minute.

Similarly, the Multilane Stick Pack – MSP 800mm model can operate up to 16 lanes, achieving up to 800 stick packs per minute.

These configurations allow manufacturers to select a machine that aligns with their specific production requirements, ensuring optimal efficiency and output.

At Unified Flex, our high-speed multilane stick pack machines are designed to meet diverse manufacturing demands. Contact us today to find the right solution for your business.

What are the essential maintenance requirements to ensure the optimal performance of a stick pack machine?

Essential Maintenance Practices for Stick Pack Machines

Ensuring the optimal performance and longevity of your stick pack machine requires regular and comprehensive maintenance. Key maintenance practices include:

1. Regular Cleaning

Consistent cleaning prevents the accumulation of dust, product residues, and contaminants that can impair machine functionality. After each production cycle, clean all accessible parts, including sealing jaws, forming tubes, and product contact surfaces, using appropriate cleaning agents. Avoid highly corrosive detergents to prevent damage to the equipment.

2. Lubrication

Proper lubrication of moving parts such as bearings, chains, and gears reduces friction and wear, ensuring smooth operation. Follow the manufacturer’s guidelines for the correct type and frequency of lubrication, while ensuring that sealing areas remain free from oil and grease to maintain packaging integrity.

3. Inspection and Replacement of Worn Parts

Regularly inspect components like belts, blades, seals, sensors, and pneumatic components for signs of wear or damage. Timely replacement of these parts prevents operational disruptions and ensures consistent packaging quality.

4. Calibration

Periodic calibration of the machine is crucial for accurate filling, sealing, and cutting. This ensures uniform product packaging and minimizes material waste.

5. Electrical and Control System Checks

Inspect electrical components, control panels, and safety devices to ensure they are functioning properly. Routine checks help prevent unexpected electrical failures and maintain safety compliance.

6. Scheduled Preventive Maintenance

In addition to daily upkeep, schedule preventive and predictive maintenance to proactively identify potential issues before they cause downtime. Professional servicing ensures that all machine components remain in peak working condition.

By following these maintenance practices, manufacturers can enhance the reliability, efficiency, and lifespan of their stick pack machines, leading to consistent production and reduced downtime.

Maximize Your Machine’s Performance with Unified Flex

For comprehensive support and tailored maintenance solutions, partner with Unified Flex. With over 50 years of combined expertise, we provide innovative, reliable, and sustainable packaging solutions, ensuring your stick pack machines operate at peak performance.

Contact us today to learn how we can support your packaging operations!

High-Performance Stick Pack Machines for Smooth Operations

From engineers refining new production lines to managers scaling output, founders entering the market, and brand leaders enhancing efficiency—your packaging solution needs to stay ahead.

Stick packs are built to solve this challenge.

Slim, portable, and consumer-friendly, stick packs have become the go-to packaging format for everything from seasonings and supplement powders to cosmetic serums and health drinks. When it comes to producing them quickly and cleanly, Unified Flex has engineered some of the best stick pack machines in the industry.

Let’s talk about how the right stick pack machine can simplify your workflow, meet your sustainability goals, and support your business growth.

What Are Stick Pack Machines?

Stick pack machines are specialized vertical form-fill-seal (VFFS) systems that create slim, elongated pouches, commonly known as stick packs. These packs are perfect for single-serve portions, making them a favorite for people with fast and active routines. From powdered coffee and drink mixes to lotions, gels, and liquid vitamins—stick packs offer a neat, portable, and user-friendly solution.

And at Unified Flex, we design stick packaging machines that work smoothly across industries and product types.

What Makes Our Stick Pack Machines Stand Out?

We’ve engineered our stick packing machines with a clear purpose—to deliver the perfect balance of speed, accuracy, and adaptability for your production line.

Here’s what sets us apart:

- Lane Configurations: Available in 1 to 16 lanes

- Output Speeds: From 40 to 800 stick packs per minute

- Max Web Width: Up to 31.49 inches (800mm) for broader packaging run

- Max Cycles Per Minute: Up to 50 cycles/min, ensuring rapid throughput

- Versatile Product Handling: Powders, granules, liquids, gels

Where Can You Use Our Stick Pack Machines?

Our stick pack product filling & sealing machinery is built for versatility—making them a smart choice across many industries:

- Food & Beverage:

Instant coffee, drink mixes, spices, sauces, sugar, and salt

- Pharmaceuticals & Nutraceuticals:

Single-dose meds, vitamins, herbal powders, and energy supplements

- Cosmetics & Personal Care:

Lotions, creams, gels, shampoos, oral care, and serums

With our machines, you can package, seal, and deliver efficiently—without compromising on quality.

Two Solutions to Match Your Production Needs

We offer two main models in our stick pack machine lineup, based on your production scale:

- Auto Pouch Bagger – AP-140 Stick Pack

Perfect for small to medium-sized businesses just getting into stick pack packaging or working with limited product volumes.

Ideal for:

- Specialty coffee

- Powdered drink mixes

- Travel-size liquids or gels

Auto Pouch Bagger Model:

Model | Max Output | Max Stick Pack Width | Max Stick Pack Length |

AP-140 | Up to 40 stick packs/minute | 1.5 inches | 7.5 inches |

- Multilane Stick Pack

When it’s time to scale up production, our Multilane Stick Pack Machines are built for speed, precision, and high-volume efficiency—all in a compact footprint. Available in configurations from 6 to 16 lanes, these machines allow you to meet growing demand without sacrificing space or quality.

Ideal for:

- Instant coffee, drink mixes, sugar, salt, sauces, and condiments

- Single-dose meds, supplements, herbal powders, and vitamins

- Protein powders, energy gels, and wellness shots

- Creams, lotions, gels, shampoos, and travel-size products

- Oral care items, liquid nutrition, and hygiene solutions

Multilane Stick Pack Models:

Model | Max Output | Max Stick Pack Width | Max Stick Pack Length |

MSP 300mm | Up to 300 stick packs/minute | 1.5 inches | 8 inches |

MSP 440mm | Up to 400 stick packs/minute | 1.5 inches | 8 inches |

MSP 800mm | Up to 800 stick packs/minute | 1.5 inches | 8 inches |

What Sealing Options Are Available for Stick Packs?

Proper sealing is critical for stick packs—not just for aesthetics, but for safety and shelf life. Choosing the right sealing method ensures your product stays fresh and secure.

- Heat Sealing: For thermoplastic films. Strong, reliable, and common in most applications.

- Ultrasonic Sealing: Ideal for sensitive or eco-friendly films. Clean, precise, and energy-efficient.

- Tear Notches & Perforated Seals: Make opening easy for consumers without tools or mess.

No matter the product, you get a clean seal, every time.

Yes, We Support Eco-Friendly Packaging

We know sustainability is no longer optional. That’s why our stick pack packaging machines are compatible with single-layer eco-friendly films, including:

- Compostable Films – PLA, PHA, biodegradable paper-based

- Recyclable Films – Mono-material PE and PP

Eco-films may need minor adjustments like low-temp sealing or improved tension control. We help you optimize performance while staying compliant with FDA, ASTM D6400, and EN 13432 standards.

Thinking green? Let’s build a packaging solution that’s efficient and sustainable.

Stick Pack Machine Prices

At Unified Flex, we believe in offering fair, transparent pricing that reflects the value, performance, and durability of our machines. Since every production line is unique, stick pack machine price varies based on your specific requirements—like the number of lanes, filling systems, film types, and custom features.

Contact us for a personalized quote—we’re happy to guide you through options.

Let’s Talk About Your Production Goals

Not sure which stick pack filling machine is right for you? Let’s discuss your production needs, budget, and product type, and we’ll help you choose the best fit.

If you’re a plant engineer planning a new line, a production manager scaling up, or a business owner launching a new product, Unified Flex Stick Pack Machines are made to fuel your expansion.

Get in touch with us today—we’ll help you choose the right stick pack machine for your needs.