In the medical world, packaging is more than a container; it’s a promise. A promise that every syringe is sterile, every swab is safe, every mask arrives ready for use. When the stakes are this high, your brand needs more than just efficiency; it needs trust built into every seal.

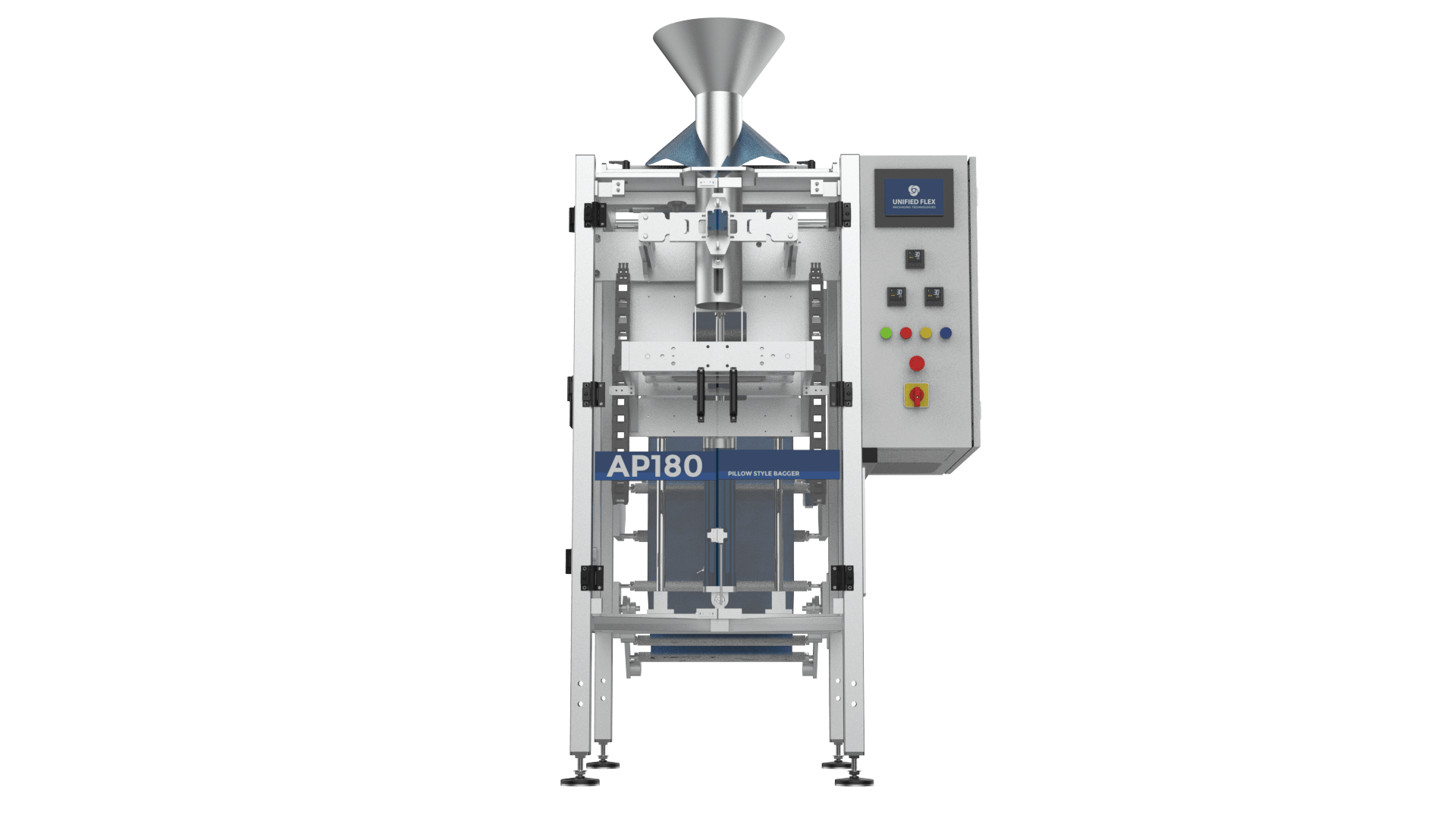

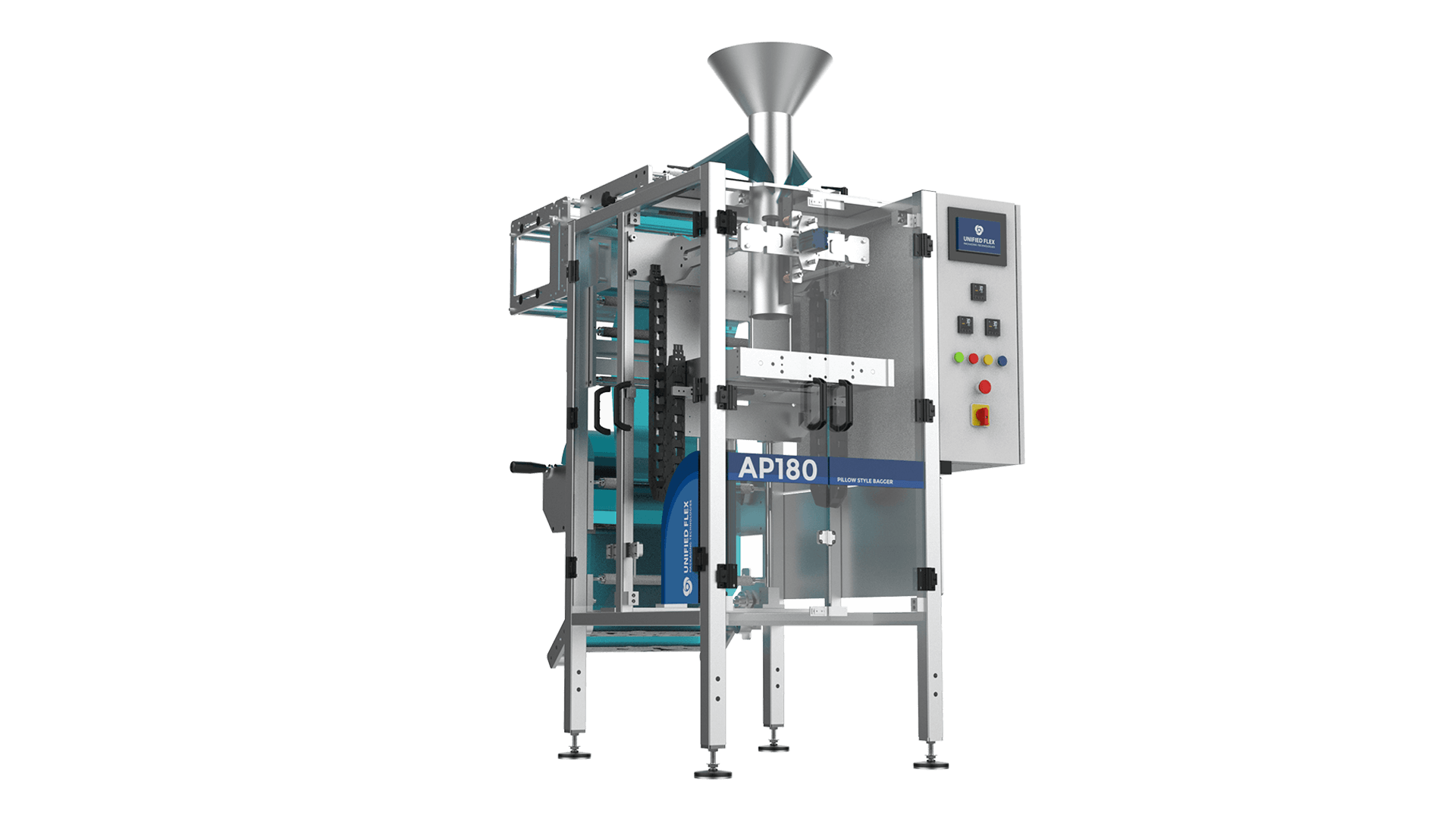

That’s why we created Auto Pouch Bagger AP-180, our flagship solution for medical device packaging. More than a machine, it’s a safeguard for products that matter most. Whether you’re packaging syringes, IV sets, test kits, or surgical tools, AP-180 delivers sterility, accuracy, and speed you can count on, so healthcare professionals can count on you.

Medical device manufacturers need packaging solutions that safeguard product sterility, streamline production, and maintain consistent quality. A dedicated medical device packaging machine provides exactly that: precise, reliable packaging that protects device integrity, improves efficiency, and scales with your business as demand grows.

Each pouch is formed, filled, and sealed in-line to protect medical devices from contamination while maintaining sterile integrity and precise fill weights. The Auto PouchBagger AP-180 medical device packaging machine automates this process, ensuring consistent dosing, strong sterile seals, and minimal product waste across a wide range of devices from powders and liquids to solid tools and test kits.

These pouches can then be:

This automated approach streamlines production, reduces operator handling, and delivers shelf-ready packaging that meets today’s healthcare standards for sterility, traceability, and sustainability.

For medical device manufacturers seeking sterile, precise, and scalable pouch packaging, the Auto Pouch Bagger AP-180 delivers. Engineered to handle the sensitive and compliance-driven nature of medical products, it combines speed and flexibility with the reliability and accuracy your operation demands.

Simple Operation

HMI touchscreen makes setup and adjustments quick and easy for any operator.

Fast Changeovers

Tool-less design minimizes downtime between product runs.

Product Versatility

Handles powders, liquids, and solid medical devices with precision.

Compact Footprint

Maximize output without needing extra floor space.

Today’s healthcare providers and regulators expect more than sterile, functional packaging. Our medical device packaging machines helps manufacturers meet sustainability goals while maintaining high output, airtight sterile seals, and professional presentation.

Our Sustainable Advantage:

Precision Material Use: Automated forming and sealing reduce excess film waste and support lean, efficient production.

Optimized Energy Efficiency: Servo-driven technology consumes less energy than traditional mechanical systems, lowering operating costs and environmental impact.

Compatible With Modern Films:

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Unified Flex packaging solutions are designed to handle a wide range of single-use and sterile medical products, including:

Our equipment is engineered to maintain sterile integrity and precision across diverse product formats.

Unified Flex serves a wide range of healthcare segments, including:

Flexible pouches are quickly becoming the preferred format for medical device packaging because they: