In the world of liquid packaging, every detail matters. One imperfect seal can mean wasted product. A minor inconsistency can turn into a recall. At Unified Flex, we understand those pressures because we’ve spent years helping manufacturers protect what they produce.

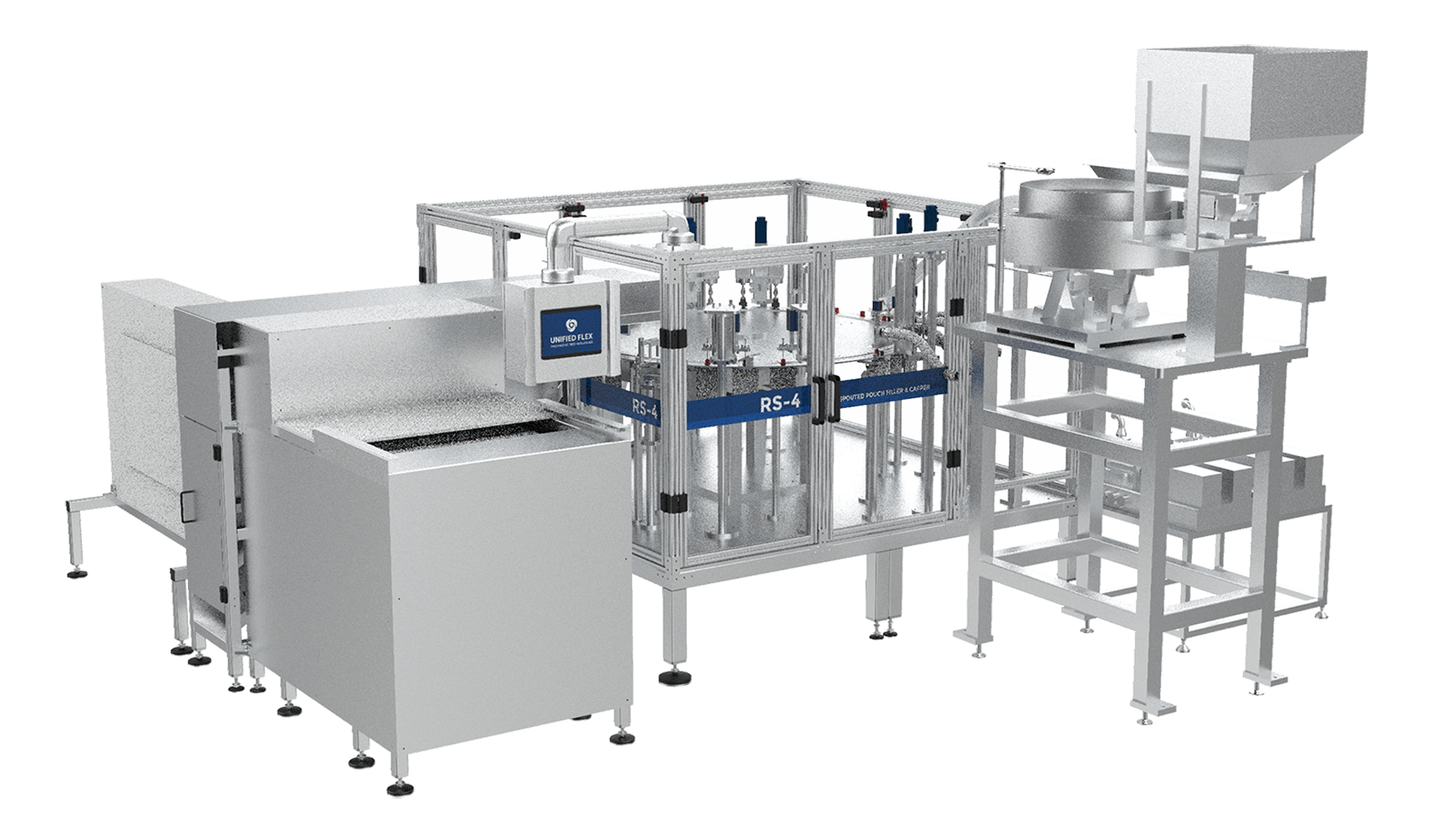

Our Spouted Pouch Filler & Capper RS-4 is not just a liquid packaging machine; it’s a complete system built around precision, reliability, and support. Whether you’re packaging sauces, baby food, juices, gels, or refills, the RS-4 gives you one thing every brand needs most, confidence.

When your packaging works flawlessly, so does your business.

Talk to a Unified Flex Packaging Specialist and discover how the RS-4 can simplify your liquid packaging line.

Liquid products bring unique challenges; viscosity changes, hygiene demands, filling accuracy, and seal integrity. Traditional bottling systems often struggle to balance efficiency with precision, and manual processes are too inconsistent to scale.

That’s why more producers are turning to spouted pouches and automated liquid packaging machines like the RS-4. It removes uncertainty from your operation delivering consistent fills, secure caps, and leak-proof results with every batch.

With Unified Flex, you’re not buying a machine. You’re gaining a packaging partner who understands your goals, your risks, and your responsibility to your customers.

The RS-4 brings structure and certainty to the liquid packaging process. It fills each pouch with precise volume control, seals with consistent temperature and pressure, and caps with uniform torque, protecting your product from production line to shelf.

The system supports a wide range of liquid products and viscosities:

Each pouch reflects what your brand stands for, quality, cleanliness, and consistency.

Reliability as a Promise

The Spouted Pouch Filler & Capper RS-4 is a high-performance liquid packaging machine built for precision, hygiene, and reliability. Designed to handle viscous and free-flowing liquids, even with particulates, it’s perfect for packaging edible oils, sauces, juices, and dairy alternatives, as well as non-food products like lotions and detergents.

Engineered with robust stainless-steel construction and advanced automation, the RS-4 delivers consistent accuracy and leak-free performance with every fill and cap. Backed by Unified Flex’s North American team of engineers and technicians, it’s a system built not just to perform, but to keep performing, day after day.

Today’s customers notice how you package, not just what you sell. The Spouted Pouch Filler & Capper RS-4 makes sustainable packaging an achievable standard. Its design reduces waste through accurate dosing and minimal film use, while its compatibility with recyclable and compostable materials lets your brand lead with responsibility.

Sustainable packaging doesn’t have to mean compromise. With Unified Flex, you achieve performance, protection, and environmental progress, all in one solution.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Yes, the Spouted Pouch Filler & Capper RS-4 supports recyclable packaging films for environmentally responsible production.

The Spouted Pouch Filler & Capper RS-4 features a hygienic design and clean-in-place capability for quick, sanitary changeovers.

Yes. The Spouted Pouch Filler & Capper RS-4 system manages everything from water-thin juices to thick sauces and gels.