Sauces and condiments don’t get second chances.

If a seal leaks, a pouch underfills, or oil separates where it shouldn’t, the product isn’t just compromised; your brand is. Flavor expectations are high, margins are tight, and customers notice when something feels off.

At Unified Flex, we understand that sauce and condiment packaging is about more than throughput. It’s about maintaining product integrity across every cycle; protecting flavor, preventing contamination, and delivering consistent, shelf-ready packages that hold up from line to table.

Our sachet packaging machines are designed to handle the unique challenges of sauces and condiments, including viscous products, oily formulations, particulates, and stringent hygiene standards. Built for precision filling, reliable sealing, and repeatable performance, Unified Flex systems enable manufacturers to package with confidence, rather than requiring constant intervention.

When sauces and condiments move in volume, packaging becomes a process-control decision. Sachets are efficient, portion-accurate, and ideal for QSR, foodservice, delivery, and sampling, but only when the system keeps seals consistent and the seal area clean across long runs.

Manual packing struggles. Generic lines get messy. And seal variation creates downstream issues in cleanup, rework, and customer trust.

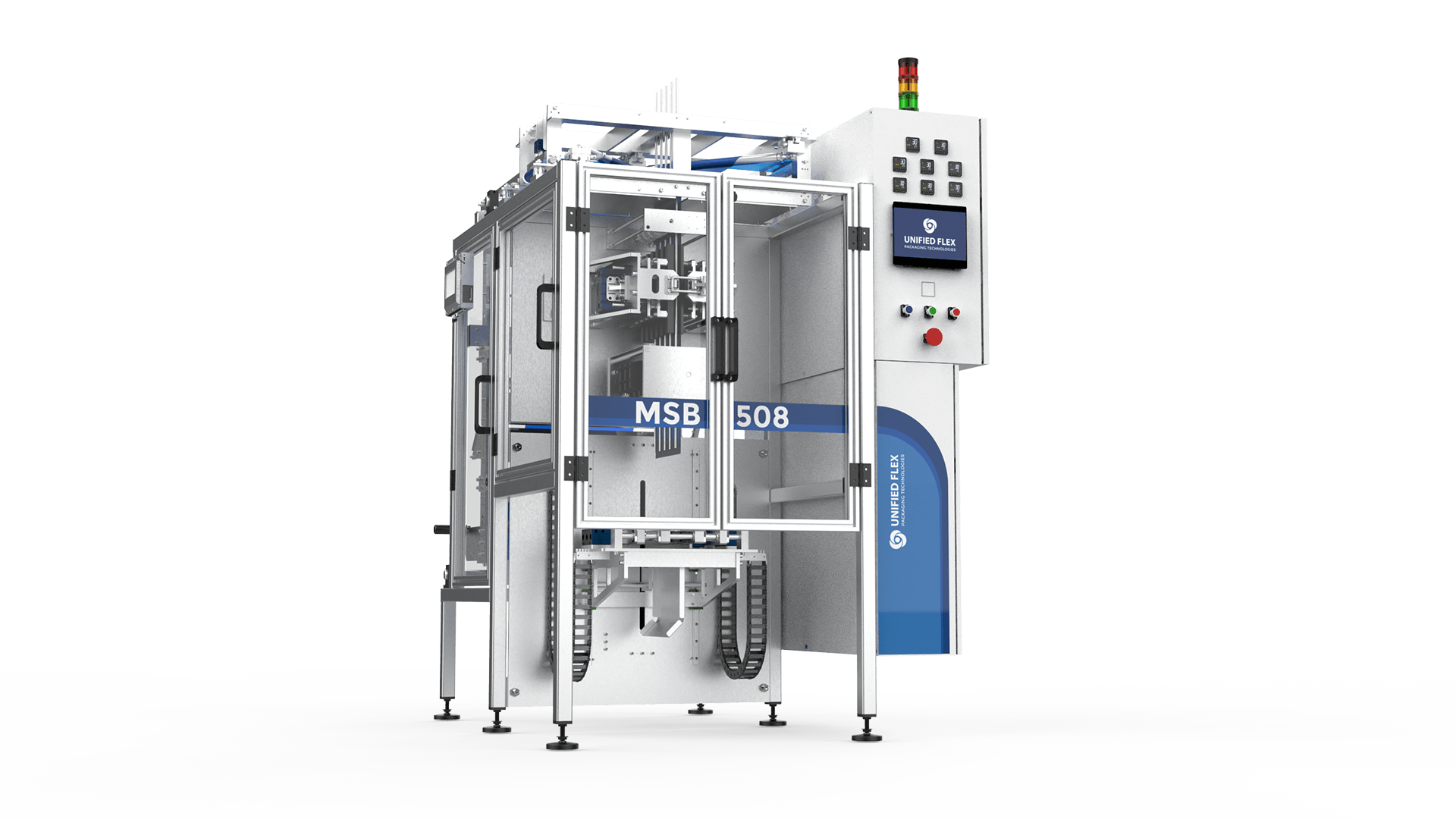

The MSB-508 eliminates those risks by delivering controlled, repeatable sachet packaging built for demanding sauce and condiment applications.

This isn’t packaging for display. It’s packaging for performance.

Sauces and condiments don’t behave like “liquids.” Some run fast and find micro-gaps. Some are thick enough to smear. Oils migrate. Light particulates don’t always stay where you want them. A stable line isn’t the one that fights those realities; it’s the one designed around them.

Through a controlled vertical form-fill-seal process, sachets are formed, filled, and sealed with synchronized motion built for consistent package quality and minimal downtime. The result is packaging that stays clean, seals reliably, and holds up through handling, the kind of repeatability sauce and condiment packaging depends on when volumes rise, and tolerance for leaks drops to zero.

Single-serve sauces travel everywhere: restaurants, delivery bags, meal kits, travel packs, and sampling programs. This system is built to package both thin and thick sauces and condiments without turning production into constant cleanup.

The Multilane Sachet Bagger – MSB 508mm is Unified Flex’s dedicated platform for demanding sauce and condiment packaging. Designed for multilane sachet production, it delivers the consistency and control required to package liquids reliably, whether they’re thin, viscous, or oil-based, without constant adjustment.

Each MSB-508 system is engineered around your product characteristics and production goals, then tested and validated before it ever reaches your floor. Built with stainless-steel construction and synchronized motion control, it’s designed to run cleanly, seal consistently, and recover quickly when production demands it.

This isn’t just equipment. It’s infrastructure for your brand.

With 2–12 lanes and up to 50 cycles per minute, the Multilane Sachet Bagger – MSB 508mm reaches up to 600 sachets per minute on 12 lanes. Output depends on fill time, sachet length, and film properties and is confirmed through testing.

Servo-driven film control and the Omron Sysmac machine controller synchronize form, fill, and seal motion in a single Digital Gear Motion, supporting consistent package quality across all lanes during long runs.

Includes intermittent motion film pull, seal function by horizontal jaws, and pneumatic horizontal seal and cut motion, plus 4 spring-loaded rotary slitting blades.

Features #304 stainless-steel construction, 90° opening vertical sealing jaws for easy cleaning, off-the-shelf non-proprietary components, compatibility with various inline thermal printers, and support for auger, volumetric, and piston fillers.

Sustainability in sauce and condiment packaging isn’t about reducing quality; it’s about reducing excess. Sachets inherently use less material than many rigid single-serve formats, and the MSB-508 is designed to support consistent production with minimal waste.

Precise output reduces giveaway. Consistent sealing reduces rejects. Stable production reduces rework. The result is packaging that supports sustainability goals while protecting product integrity and food safety.

This is responsibility built into the process, not added later.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

For sauces and condiment packaging, sachets are the most widely used format because they support precise portion control, strong perimeter seals, and efficient high-volume automation. In foodservice, delivery, travel, and sampling programs, sachets offer a balance of product protection, shipping efficiency, and consistent user experience that rigid formats struggle to match.

From a production standpoint, sachets are also well-suited to sauces and condiment packaging machines because they can be formed, filled, and sealed in a controlled, repeatable process. This matters when running sauces that vary in viscosity, oil content, or temperature, where seal cleanliness and consistency directly affect leak rates and downtime.

Depending on portion size and dispensing behavior, condiment packaging may use standard sachets or longer sachet formats. Final sachet dimensions are selected based on product flow, fill accuracy requirements, case packing, and how the condiment will be handled downstream. Contact us to determine the most reliable sachet format for your condiment packaging line.

When selecting a sauce and condiment packaging machine, speed alone is not a reliable indicator of performance. The more important factors are seal repeatability, film control, and how the system manages real sauce behavior over long production runs.

A properly designed sauce and condiment packaging machine should maintain consistent form-fill-seal timing, minimize product migration into seal areas, and allow stable operation across different viscosities. It should also support the appropriate filling method and provide practical access for cleaning, since sauces and condiments introduce residue that can quickly affect uptime if the machine is difficult to service.

Evaluating these factors early helps prevent issues like intermittent leaks, excessive scrap, and long restart times. Schedule a consultation to review your condiment packaging requirements and determine the right machine configuration.

Some sauces and condiments are harder to run on a condiment packaging machine because their flow behavior increases the risk of seal contamination and inconsistent package integrity. Thin condiments can migrate quickly and expose small seal weaknesses. Thick sauces can smear during filling. Oils can travel into sealing areas, and light particulates can interfere with clean sealing if the process isn’t controlled.

For reliable condiment packaging, the machine setup has to match the product: filler type, sachet geometry, seal timing, and cleaning access all matter. When those are aligned, leaks drop, scrap drops, and output stays stable over time.