Cocoa powder. Baking mixes. Pancake batter blends. Instant beverages. Seasonings. The food powder market is rapidly evolving, with pillow bags emerging as preferred formats for both single-serve and family-size products. Consumers are seeking freshness, convenience, and sustainability, while retailers are prioritizing clean design, portion control, and shelf efficiency. Industry data shows that brands adopting modern food powder packaging solutions are gaining momentum in both retail visibility and operational performance.

From specialty cocoa to protein blends destined for global markets, our food powder packaging machines deliver speed, cleanliness, and cost-efficiency at every stage of your process. By moving beyond bulky tubs and rigid containers to precise, airtight packs, you can deliver high-quality powders in packaging that meets modern expectations and position your brand as a leader in today’s competitive food powder category.

Powders aren’t forgiving. Cocoa dust can wreck seals. Baking mixes clump. Protein blends lose potency if exposed to air. Outdated systems don’t cut it.

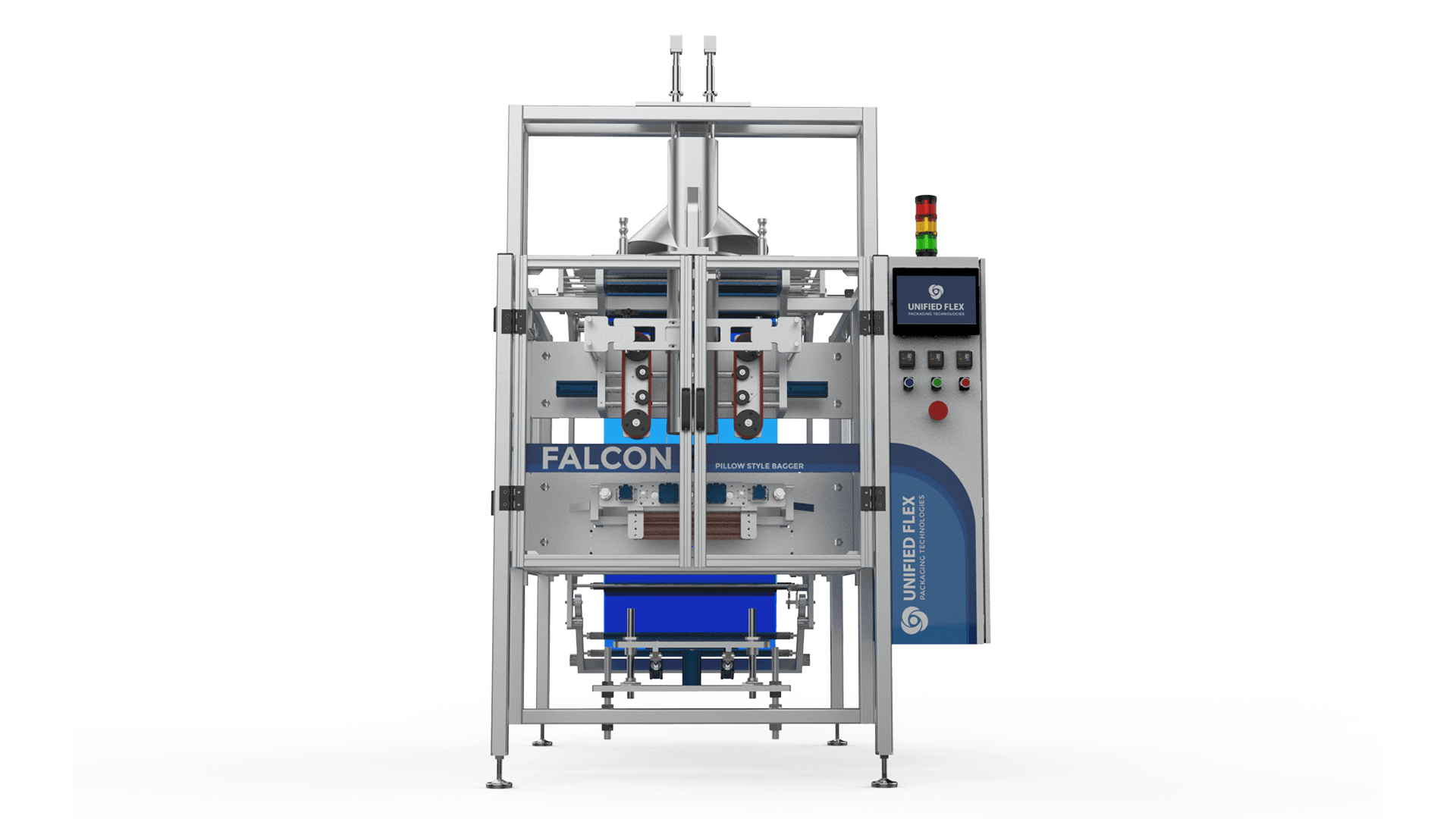

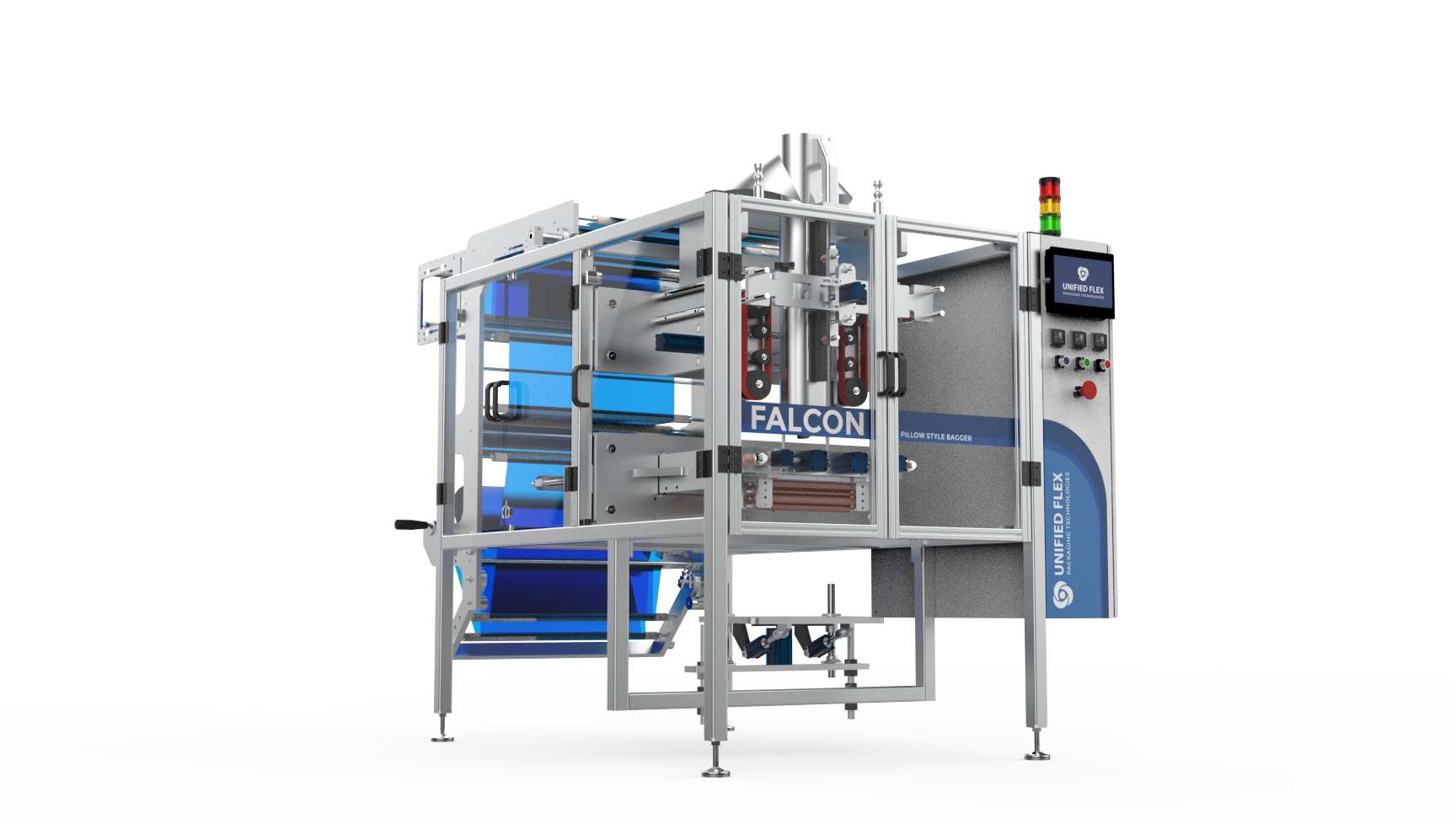

The Vertobagger Falcon was built to solve these problems and give you packaging that sells harder than you do. By shifting to specialized food powder packaging, you not only protect your product but also increase throughput, cut waste, and deliver a premium customer experience.

Every pack tells your story. The Vffs Vertobagger Falcon automates it flawlessly, dosing powders with surgical accuracy, forming beautiful packaging, and sealing it for freshness that lasts.

What that means for your business:

This is how food powder packaging machines become growth engines, not just equipment.

For powdered food producers seeking consistent, clean, and scalable pillow bag packaging, the Vertobagger Falcon delivers. Designed to run up to 100 bags per minute and handle pillow bags, eurohole, and side-gusseted formats, it combines speed and precision with stainless-steel durability.

Intuitive Controls

7” touchscreen with Omron PLC makes setup, diagnostics, and operation simple at any skill level.

Seal Integrity & Accuracy

Servo-controlled belts, pneumatic jaws, and digital temperature control ensure tight seals and consistent bag lengths.

Low-Maintenance Design

Tool-less forming collar swaps, quick belt changeovers, and open stainless-steel frame construction make cleaning and maintenance fast and efficient.

Retail-Ready Flexibility

Handles pillow bags, pillow bags with euroholes, and side-gusseted formats to meet retail and display demands.

Today’s buyer doesn’t just care what’s inside, they care about what it’s packed in. Vffs Vertobagger Falcon makes it easy for your brand to deliver eco-conscious food powder packaging without slowing production.

Sustainable advantages:

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Our food powder packaging systems are designed to package a wide range of powdered foods, including cocoa, flour, baking mixes, protein and nutrition blends, instant beverages, spices, and seasonings. They deliver consistent performance across fine, dusty powders as well as denser mixes.

Powders are highly sensitive to moisture and dusting. Our machines use servo-controlled pulling belts, pneumatic sealing jaws, and digital temperature control to create airtight seals that lock in freshness. Combined with high-barrier films and optional nitrogen flushing, this ensures powders stay free-flowing, aromatic, and shelf-stable.

Yes. These systems are designed to grow with your operation. Whether you’re starting with small-batch runs or expanding to high-volume production, they offer fast changeovers, customizable bag sizes, and modular configurations; making it easy to scale without compromising efficiency or consistency.