Snacking isn’t a side hustle anymore, it’s the main event. Organic trail mixes, vegan chips, protein bites, dried fruits, plant-based crackers, cocoa-dusted almonds… the shelves are bursting, and the competition is fierce. The winners? Brands that package smarter.

Today’s consumers don’t want tubs that waste space or boxes that go stale. They want fresh, resealable, Instagrammable packs that slip into backpacks, gym bags, and Whole Foods baskets. That’s where we come in. Our snack packaging machines give you the formats, the speed, and the flexibility to turn good snacks into craveable brands.

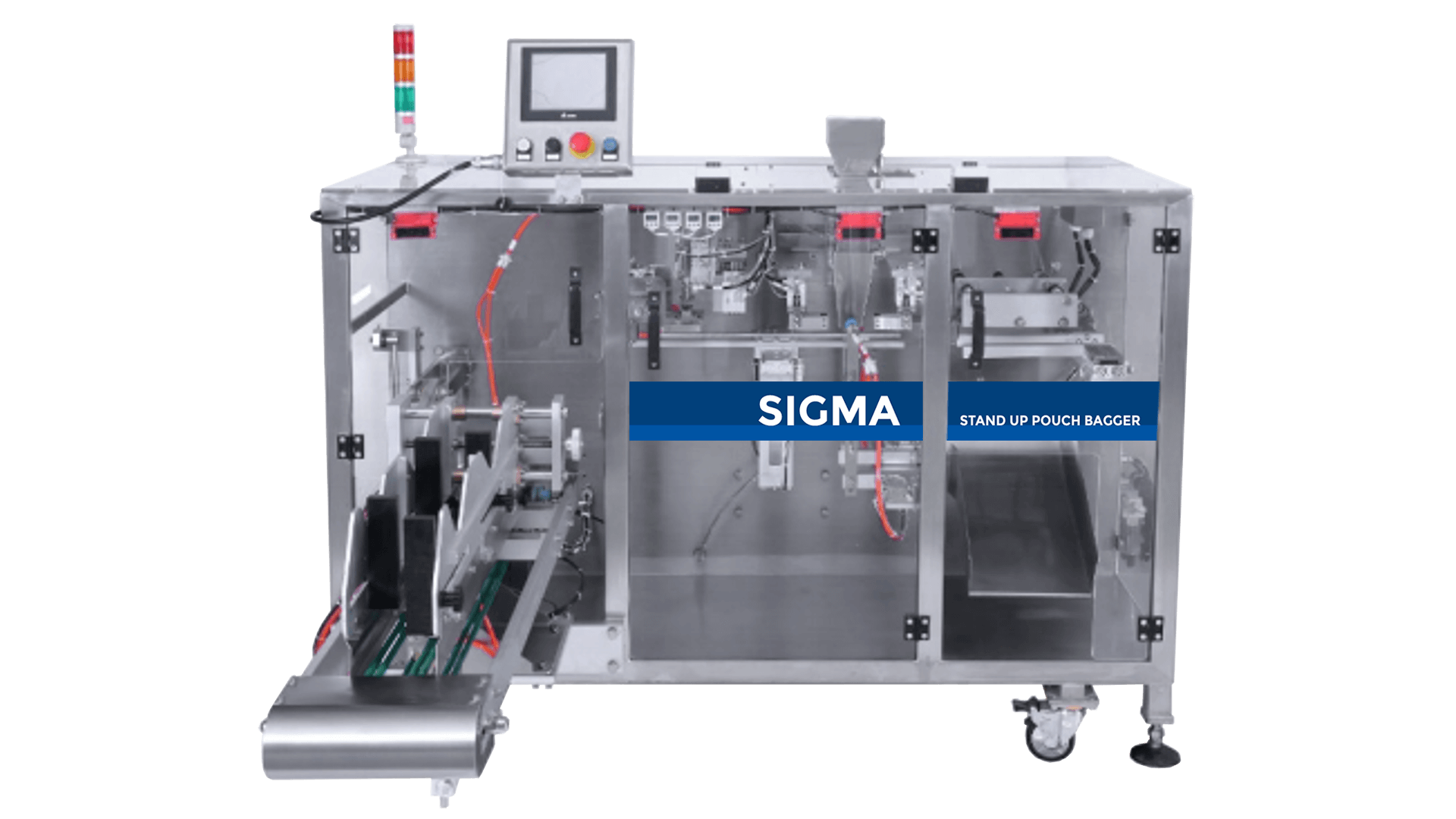

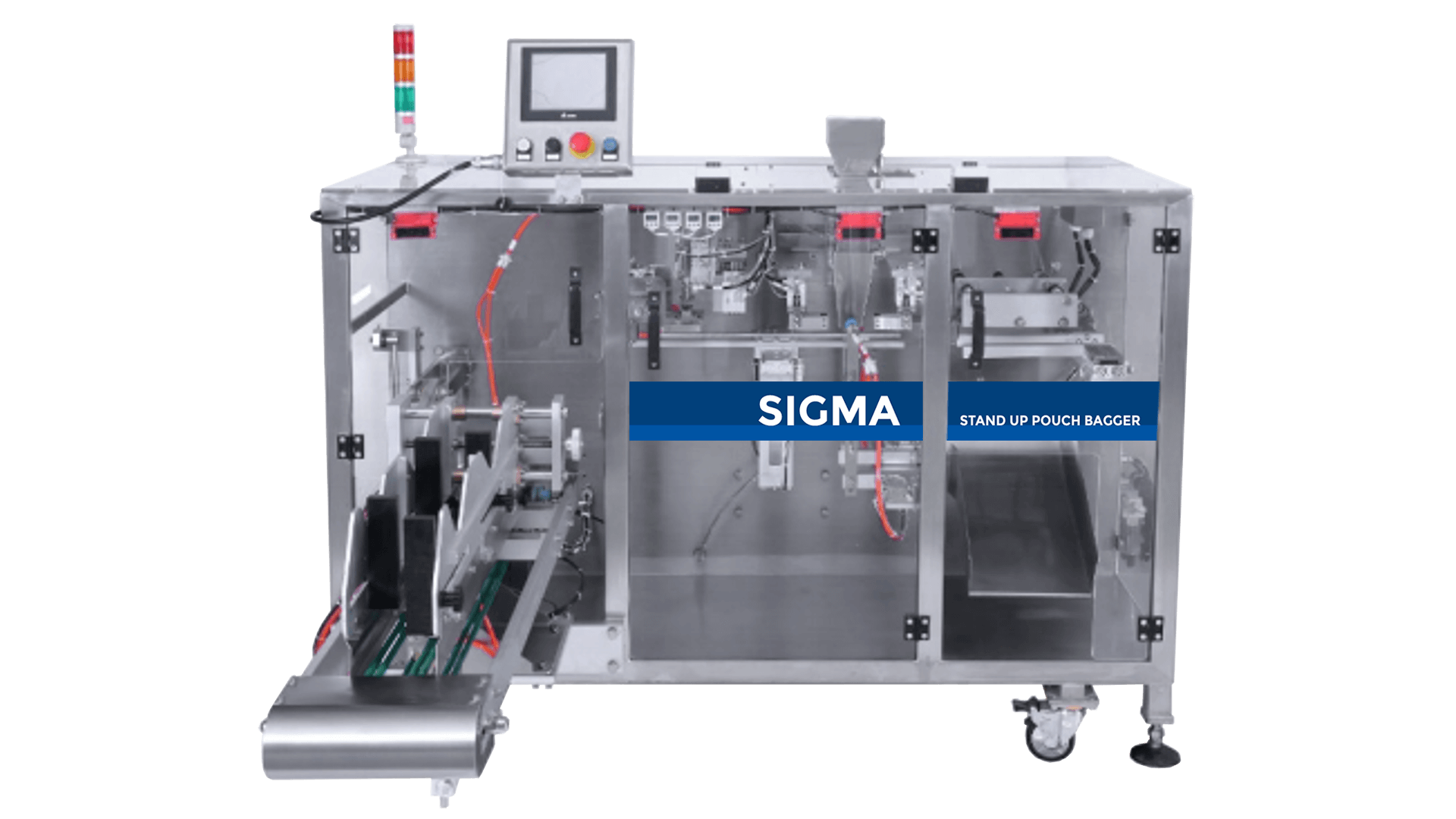

In the fast-moving world of healthy snacks, packaging does more than protect; it defines your brand. Shoppers expect convenience, freshness, and eco-friendly materials, while retailers demand formats that move quickly from pallet to shelf. That’s where the DOY Sigma comes in. It creates packaging that not only safeguards quality but also scales effortlessly with your growth, whether you’re running limited batches of organic snacks or high-volume production for national retail.

With our reliable snack packaging machines, your production line runs fast, smooth, and precise:

Fill: Consistent, accurate dosing to protect product integrity and portion control.

Seal: Airtight heat sealing locks in freshness and flavor, keeping snacks crisp and shelf-stable.

Deliver: Finished packages ready for retail shelves, e-commerce orders, or direct-to-consumer shipments.

Consumers love it because they get fresh, resealable, on-the-go packaging. Brands love it because it reduces waste, labor demands, and logistics costs while supporting sustainable growth.

The DOY Sigma is built for modern snack brands chasing growth. Engineered for high-performance and flexibility, it delivers precision packs that keep snacks fresh and shoppers impressed. From organic granola to vegan chips, DOY Sigma gives your products the packaging edge they need.

Quick changeovers minimize downtime and increase efficiency.

Durable #304 stainless-steel construction with user-friendly touchscreen controls.

Today’s buyers and retailers expect more than just a functional package. Our snack packaging machines help producers meet sustainability goals while maintaining high output, reliable sealing, and a clean, premium shelf presentation.

Our Sustainable Advantage:

Precision Material Use: Automated dosing and tight seal control help reduce overfill and excess film consumption.

Optimized Energy Efficiency: Servo-driven systems are engineered to consume less energy than conventional mechanical setups.

Compatible with Modern Films:

Recyclable Films: Durable, food-safe, and sustainable options.

Compostable Films: Certified under ASTM D6400 standards for environmentally responsible packaging.

With these features, brands can confidently package snacks like granola, trail mix, and plant-based bites in eco-friendly formats without compromising freshness or performance.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Our snack packaging machines are designed to handle a wide variety of products, including granola, trail mix, nuts, dried fruit, protein bites, chips, crackers, and other snacks. They deliver consistent performance whether you’re packaging delicate, fragile items or bulkier snack products, ensuring every package is secure and shelf-ready.

Snacks are highly sensitive to oxygen and moisture. Our snack packaging machines use digital temperature controllers to ensure precise, consistent seals that lock in freshness and flavor. When combined with high-barrier recyclable or compostable films, this helps prevent staleness and maintain product quality. For oxygen-sensitive snacks like granola and baked goods, optional nitrogen flushing provides extra protection, extending shelf life and reducing food waste.

Yes. Our snack packaging machines are built for versatility, allowing you to run a wide range of formats on a single system. These include pillow bags, 3-side and 4-side seal bags, box pouches, flat-bottom 4 corner bags, and stand-up pouches. This flexibility makes it easier to manage multiple SKUs, adapt to seasonal product launches, and meet diverse retailer demands without the need for additional equipment, ultimately saving space and reducing production costs.