To stay competitive, you need more than manual fixes or patchwork solutions. You need a system that delivers at scale, every time.

Our Gel Pack Packaging Machine is built for that exact challenge. It combines high-speed output with hygienic operation and pinpoint dosing, so every pack meets quality standards without slowing you down. No leaks. No rework. No inconsistency. Just clean, efficient performance that keeps your supply chain moving and your customers satisfied.

In today’s market, packaging isn’t just a step in the process; it’s the engine behind your growth.

With rising demand for temperature-sensitive products, businesses need packaging solutions that are reliable, scalable, and sustainable. Our gel pack packaging machines deliver just that, making them the go-to choice for efficient and consistent performance.

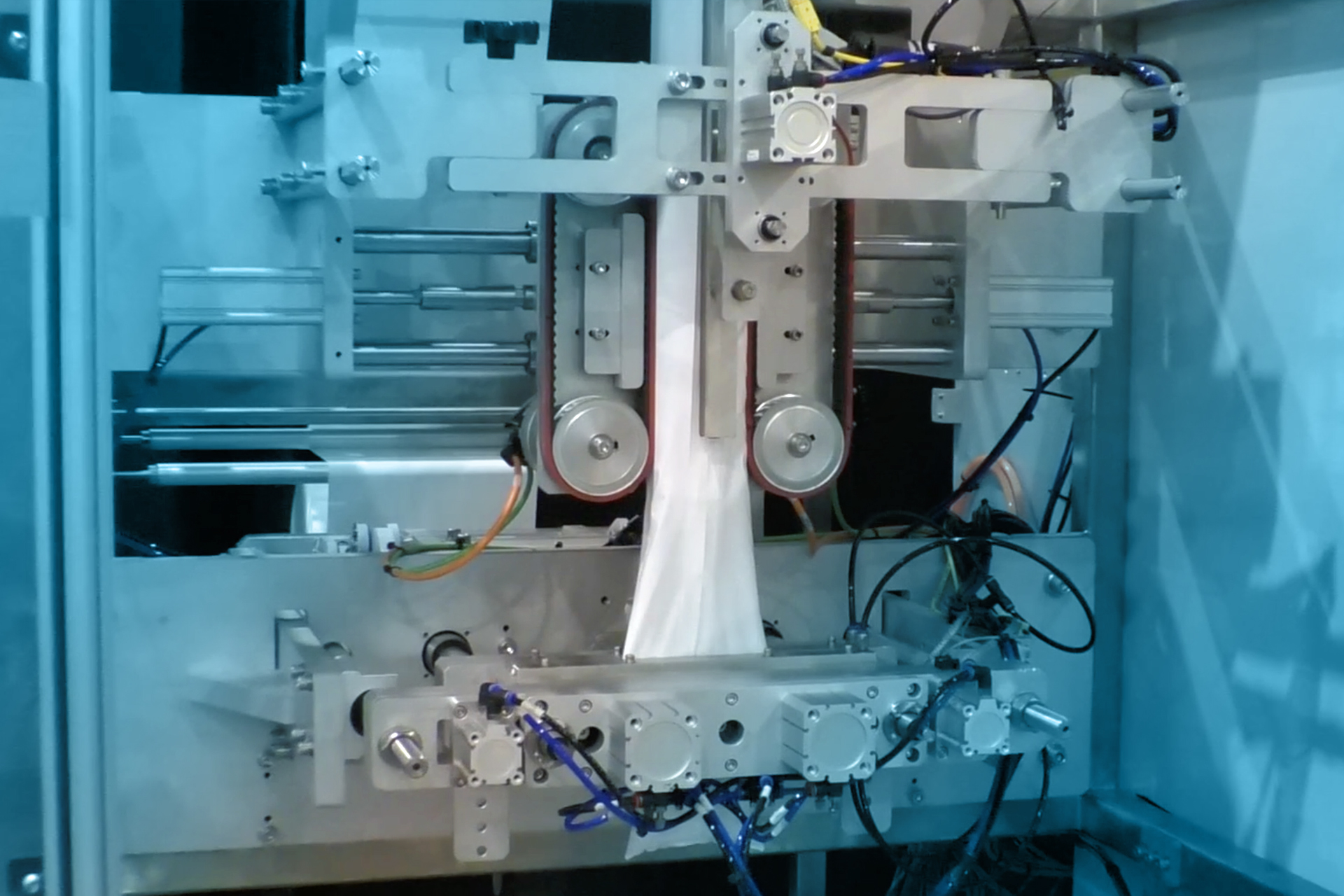

Our gel pack packaging machines automate the entire process; forming, filling, and sealing each pouch with precision. Gel packs are filled to exact specifications and sealed using pneumatic jaws and precise temperature control to ensure leak-proof performance.

Once packaged, gel packs can be:

• Frozen or chilled for long-term cold chain use

• Shipped in bulk or as part of product kits

• Used in medical, food, or industrial applications where consistent temperature control is critical

This automated process reduces manual handling, improves hygiene, and ensures consistent product quality across every batch.

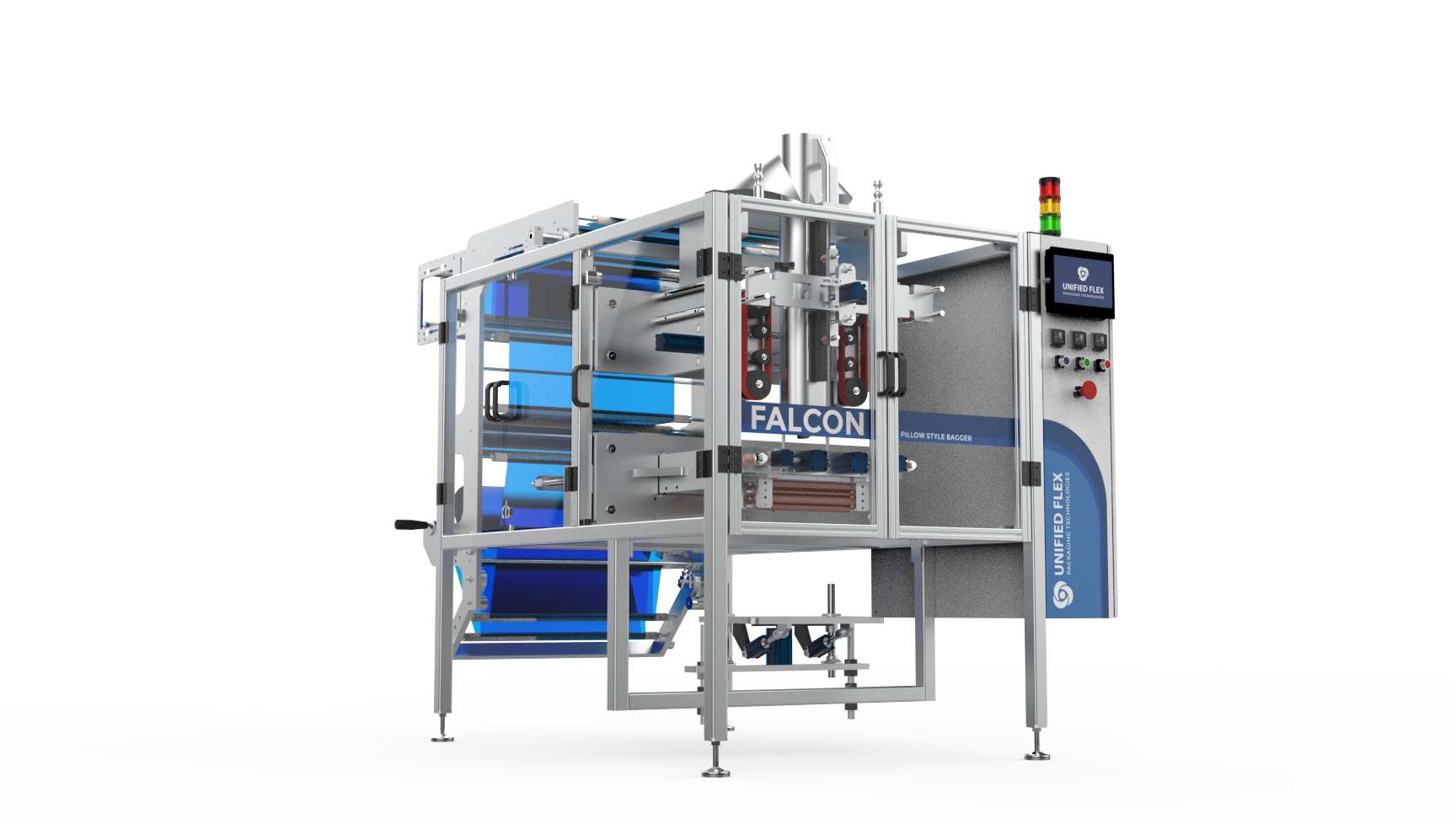

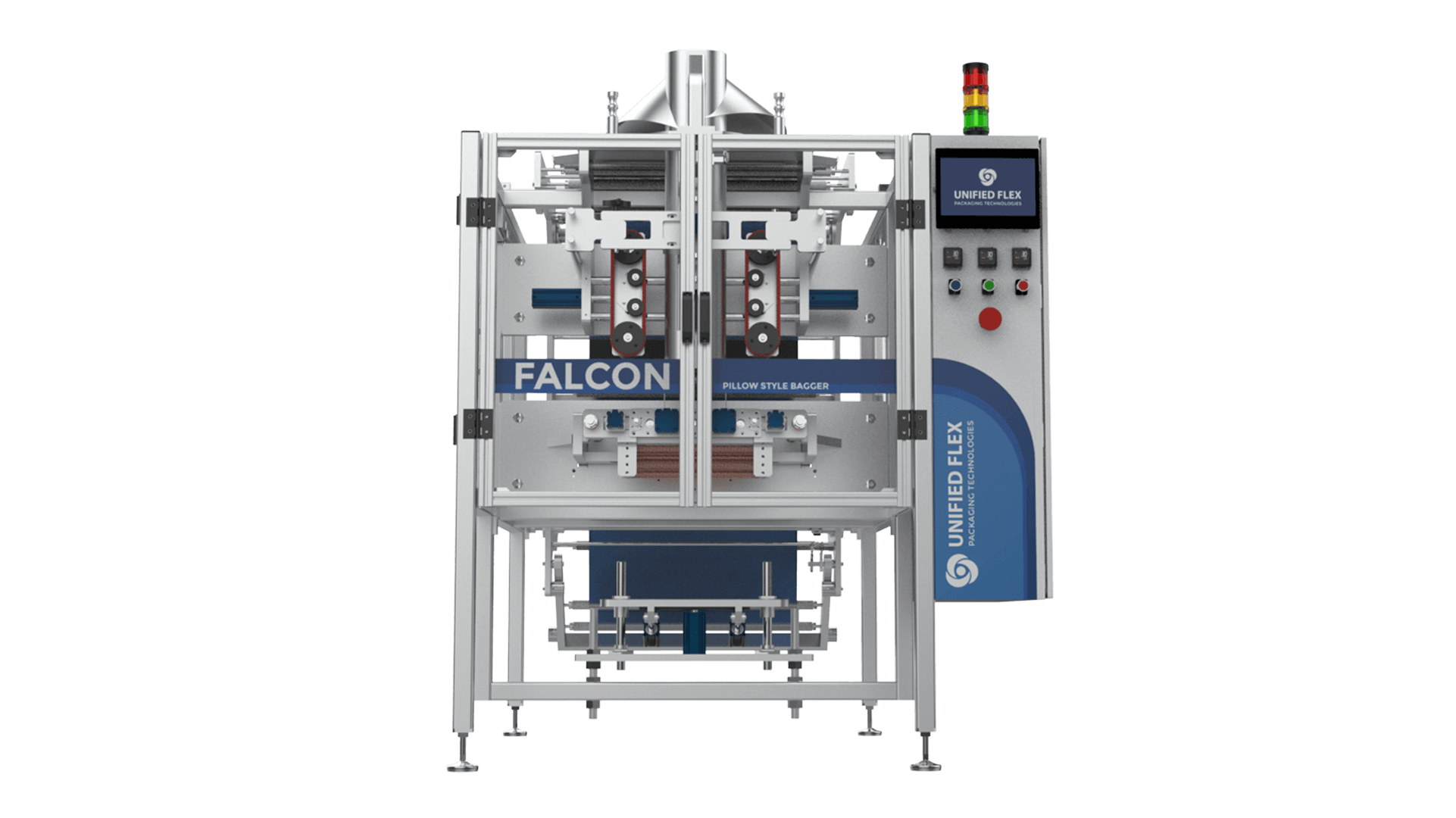

The VFFS Vertobagger Falcon is our flagship gel pack packaging machine, offering dependable automation for both growing businesses and high-volume production. Compact in design and robust in performance, it’s an ideal solution for businesses looking to streamline their packaging processes.

Hygienic Stainless Build: Easy-to-clean #304 stainless steel construction keeps gel pack production sanitary.

Range of Bag Styles: Runs pillow bags and side-gusseted bags to meet diverse gel pack formats.

Fast & Efficient: Up to 100 packs per minute to keep high-volume gel production moving smoothly.

Consistent Quality: Delivers reliable sealing and filling for uniform, professional results.

As eco-conscious consumers expect more sustainable packaging, manufacturers need practical solutions. Our gel pack equipment is built for this reality, supporting eco-friendly materials that reduce environmental impact without sacrificing quality.

Our Sustainable Advantage

Yes. We offer both compact and larger configurations to suit a range of production needs. For facilities with limited floor space, there are space-saving options, while higher-capacity machines are available for increased output. The VFFS Vertobagger Falcon, for example, is designed to maximize space efficiency without compromising performance, supporting scalable production.

Yes! Our machines are engineered to handle a wide range of viscosities from water-like liquids to thick gels; ensuring reliable, consistent packaging every time.

Unified Flex provides comprehensive support, including training, troubleshooting, and preventative maintenance services, ensuring optimal machine performance and longevity.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.