The health & wellness boom isn’t slowing down and neither should you. Sachets are rewriting the rules of protein packaging, and brands that embrace them aren’t just evolving, they’re dominating.

Why? Because modern consumers want more: grab-and-go ease, dead-on accuracy, and planet-friendly packaging. And sachets deliver, beautifully.

From single-serve fuel packs to multi-use refills, sachets keep your product fresher, your brand sharper, and your shipping costs lower. Whether you’re just starting out or scaling up, our protein powder packaging machines make it easy to ditch the tubs and move to a system that’s lean, clean, and built for growth.

Protein powder brands need smart, flexible packaging solutions that address real challenges like settling, inconsistent fills, and bulky, outdated jars. Our protein powder packaging machines deliver exactly that. Cost-effective, scalable sachet packaging that reduces waste, improves fill accuracy, and meets consumer demand for clean, convenient, on-the-go options, perfect for both retail shelves and e-commerce orders.

Each sachet is formed, filled, and sealed with precision, locking in product quality and giving you a professional, uniform format. Our protein powder packaging machines handle this process automatically, minimizing manual labor and maintaining hygiene standards.

These sachets can then be:

With flexible fill volumes and a range of film options, this approach gives you a dependable, scalable way to meet market demand while managing operational costs.

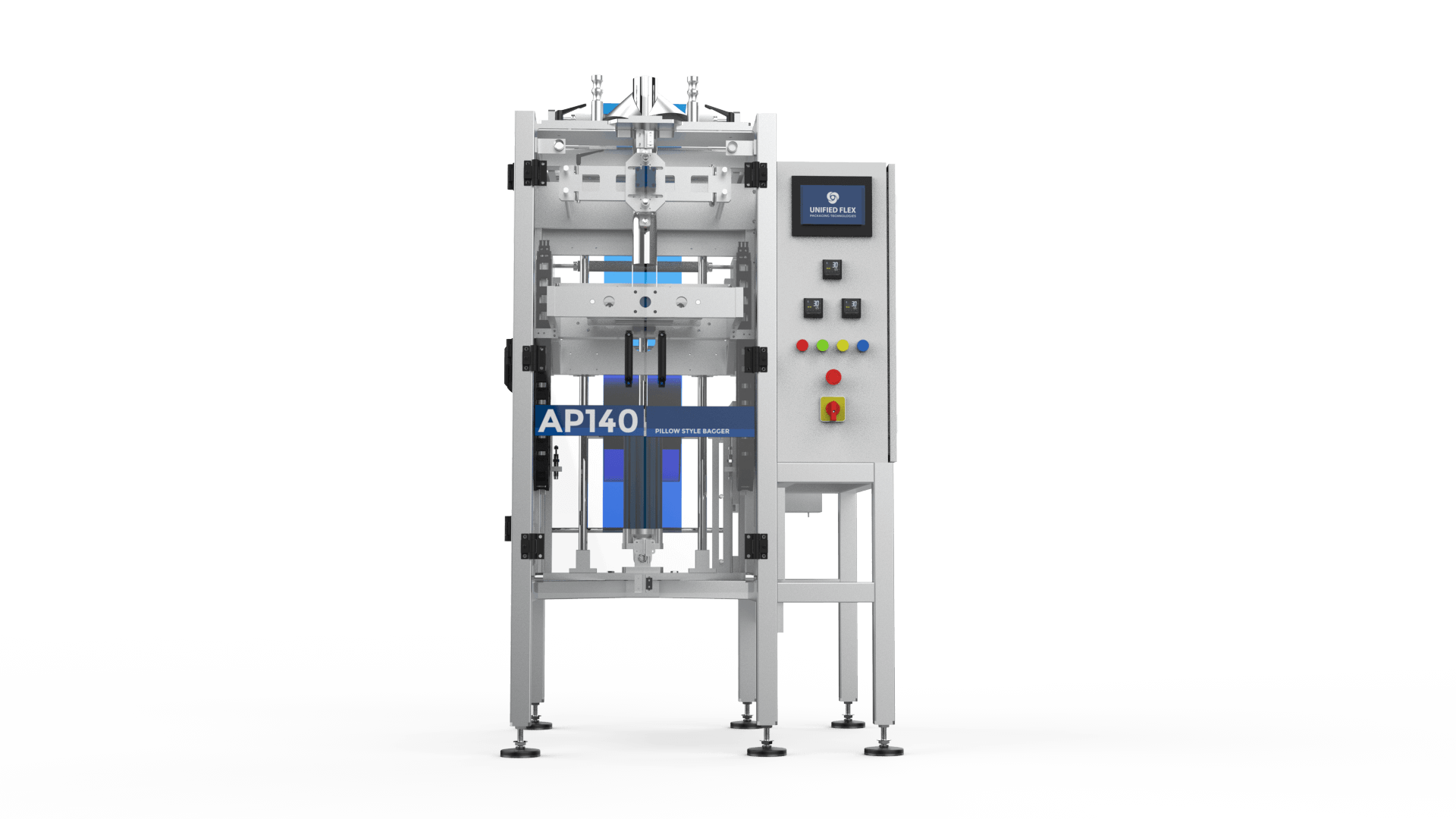

For brands looking to package protein powder in 4-side seal sachets, the Auto Pouch Bagger AP-140, paired with the AF-200 Auger Filler delivers precision, flexibility, and consistent performance. Designed for low-volume, on-demand, and R&D production, this machine setup is ideal for emerging supplement brands and co-packers preparing to scale.

Eco-conscious consumers are demanding more from the brands they trust. Our protein powder sachet packaging systems are designed to meet those needs, offering an eco-friendly, sustainable packaging solution that doesn’t compromise product quality or convenience.

Our Sustainable Advantage

Unified Flex provides comprehensive support, including training, troubleshooting, and preventative maintenance services, ensuring optimal machine performance and longevity.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Yes, our protein powder packaging machines are designed to handle a variety of pouch sizes, from small single-serve sachets to larger multi-serve packs, providing flexibility for different protein powder products and market needs.

Yes, our auger fillers are specifically engineered to handle fine powders like protein, ensuring accurate fill weights and minimizing waste during production.

We offer compact packaging machines available in a range of capacities to meet diverse production needs. Whether you’re operating in a small facility or seeking to increase output without compromising valuable floor space, our equipment is designed to deliver exceptional efficiency. Each model is thoughtfully designed to make the most of your available space while supporting reliable, scalable production to help your business grow.