Outdated bottling lines and manual workarounds slow you down, and your competitors are gaining ground. To lead in a fast-moving market, you need packaging systems that keep pace with demand.

That’s where our Shampoo Packaging Machines come in. Engineered for precision and performance, these machines ensure accurate dosing, hygienic filling, and airtight sealing every single time. Say goodbye to spills, waste, and rework. Say hello to consistent quality, higher throughput, and satisfied customers.

In today’s world, packaging isn’t just a necessity; it’s your production powerhouse. Let our Shampoo Packaging Machines drive your growth, one perfectly packed sachet at a time.

With growing demand for flexible formats, businesses need solutions that are reliable, scalable, and efficient. Our shampoo packaging machines deliver exactly that, making them the preferred choice for consistent, high-quality production.

Each sachet is pre-measured and sealed to preserve the integrity and quality of your shampoo. Our machines automate this process, filling each sachet with the perfect amount of product and sealing it securely in high-quality, eco-friendly flexible packaging films.

These sachets can then be:

This modern, efficient solution reduces labor, enhances hygiene, and aligns with consumer preferences for convenient, sustainable packaging.

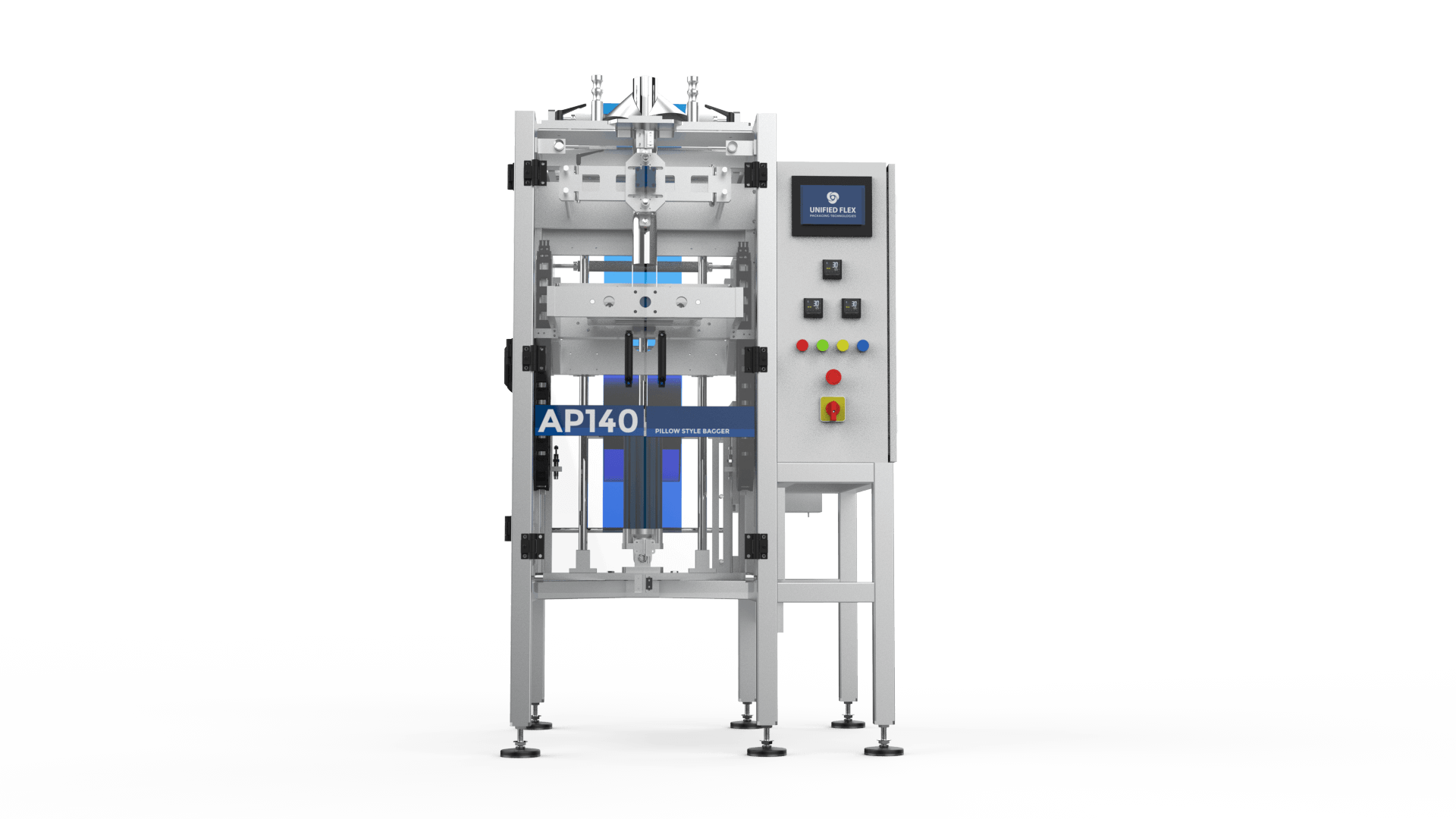

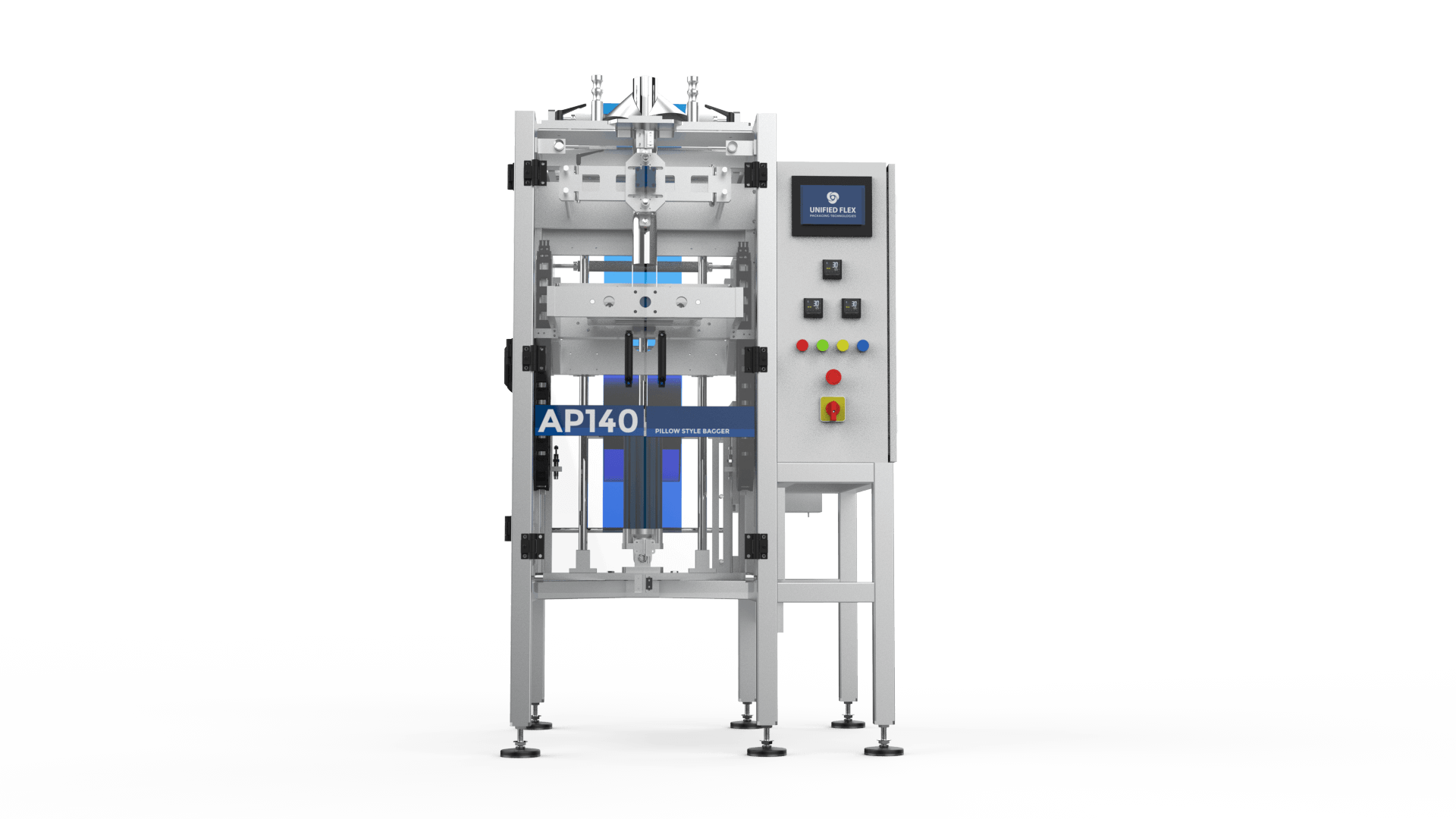

The Auto Pouch Bagger AP-140 paired with a viscous piston filler offers a smart, space-efficient solution for shampoo brands ready to scale. This compact vffs system is ideal for automating sachet packaging of thicker liquids like shampoo with precision and consistency.

• Built for Viscous Products: The piston filler ensures accurate dosing without clogging or splashing.

• Compact & Modular: Designed to fit small production floors while staying easy to expand or upgrade.

• Fast Setup, Minimal Downtime: Tool-less changeovers and intuitive controls reduce setup time and keep your line running.

• Clean, Hygienic Design: Stainless steel contact parts and easy access panels simplify cleaning and maintenance.

Eco-conscious consumers expect more from personal care brands. Our shampoo sachet packaging systems are designed to meet those expectations, helping you reduce environmental impact while delivering a premium, mess-free user experience.

Our Sustainable Advantage

• Precision Material Use: Each sachet is filled with exact amounts, minimizing both product and film waste.

• Energy-Efficient Design: Uses less power than traditional bottle-filling lines, lowering your overall energy footprint.

• Eco-Friendly Packaging Options:

Unified Flex provides comprehensive support, including training, troubleshooting, and preventative maintenance services, ensuring optimal machine performance and longevity.

Our packaging machines are designed for easy upkeep with routine cleaning and lubrication. With proper care, they are built to perform reliably over time.

We provide financing exclusively through Ascentium Capital, with flexible terms and quick approvals. For details on how to secure financing with no upfront costs, click here to learn more.

Yes, our shampoo packaging machines are designed to run a wide range of pouch formats, from single-use sachets to larger packs, offering flexibility for different market needs.

Absolutely. Our piston fillers are engineered to handle thick, creamy formulations without compromising flow control or package integrity.

Our shampoo packaging machines are available in a range of sizes to suit different production environments. Whether you’re working with limited space or require a higher output capacity, we offer compact and larger configurations that maximize efficiency while accommodating your facility. Each machine is designed to optimize floor space while maintaining high-performance standards for scalable production.