The smoothie market is rapidly evolving, with grab-and-go sachets emerging as the format consumers increasingly prefer for convenience, sustainability, and freshness. Industry data shows smoothie brands adopting this innovative packaging are experiencing significant growth in both retail placement and customer loyalty. Whether you’re a boutique smoothie brand or scaling to meet national demand, our smoothie packaging machines make your production process seamless, sustainable, and scalable. By transitioning from traditional bottles to efficient, eco-friendly sachets, you can deliver the nutritious, ready-to-blend smoothies that today’s health-conscious consumers are actively seeking, and position your brand at the forefront of this industry shift.

Smoothie brands need smart, flexible solutions that align with evolving consumer values and deliver operational efficiency. Our machines provide exactly that: cost-effective, scalable packaging for smoothies that protects product quality and enhances brand appeal.

Each sachet is pre-measured and sealed to lock in flavor, freshness, and nutrients. Our machines automate this process, filling each sachet with precise quantities and sealing them in high-quality, eco-friendly films.

These sachets can then be:

• Frozen for long-term storage and grab-and-go convenience

• Sold in packs for retail or direct-to-consumer shipping

• Easily blended by consumers, just add liquid and blend, no prep required

This modern solution reduces labor, improves hygiene, and meets consumer expectations for ease and freshness.

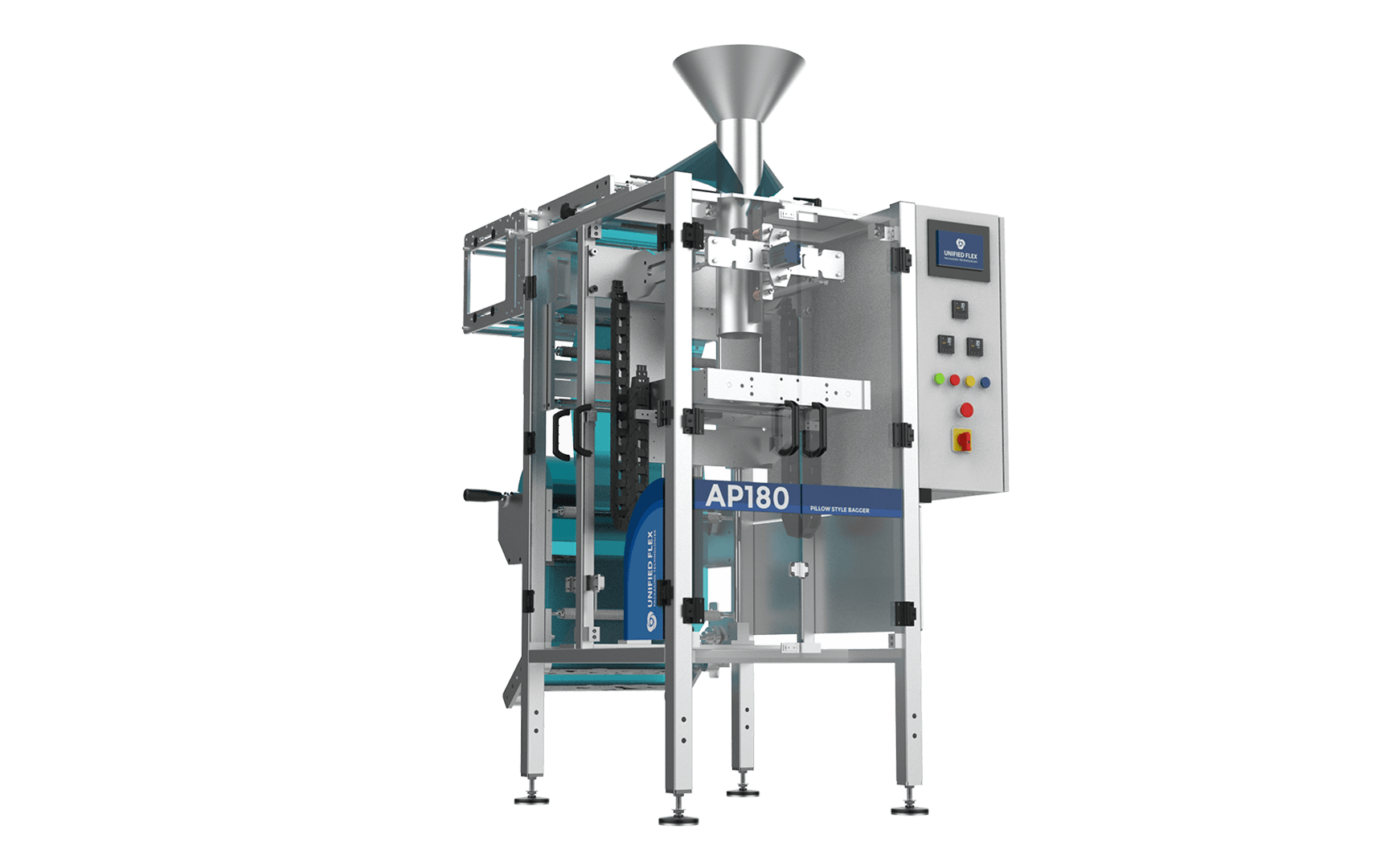

The Auto Pouch Bagger AP-180 is our flagship smoothie packaging machine, designed for small to medium-sized businesses looking to automate and grow. With its compact design and high performance, it’s the perfect entry point into sachet automation.

Eco-conscious consumers are driving change. Our smoothie packaging machines support your environmental goals while delivering premium product presentations.

• Precision Material Use: Reduce waste through accurate dosing and packaging.

• Energy-Efficient Systems: Lower energy usage than traditional packaging setups.

• Eco-Friendly Materials:

Yes! Our machines are built to handle everything from liquid smoothies to fibrous, textured blends with consistent results.

Very little. The design prioritizes easy cleaning and long-term performance with simple part replacements.

Absolutely. We partner with Ascentium Capital to offer up to $2M in financing with no money down and low monthly payments. Quick approvals up to $400K. Explore Our Financing Options.

Most clients complete the transition within 4-6 weeks. Our team provides comprehensive training and implementation support to ensure minimal disruption to your production schedule. Many customers are able to run both packaging systems simultaneously during the transition period, gradually scaling up sachet production as market demand increases

Our Auto Pouch Bagger AP-180 model requires only 73″ x 41″ x 52″ of floor space, making it ideal for operations with limited production area. The machine’s compact design integrates seamlessly into existing production lines, providing output of up to 40 sachets per minute. Our larger models naturally require more space, but we offer complimentary facility assessment to ensure optimal placement and workflow integration.