Popsicle Packaging Machines

Popsicle Packaging Machines

Achieve Consistent Package Quality and Reduced Downtime

Popsicle Packaging Machines from Unified Flex are an increasingly popular piece of machinery in the industry today.

These advanced machines can produce 4-sided and 3-sided seal long sachet packages. They produce popsicle packaging with a maximum bag width of up to 4 inches and a maximum web width of up to 16 inches for popsicles or freeze pops. These machines operate at an impressive rate of 200 sachets per minute, depending on factors such as the number of lanes, filling time, viscosity, and sachet length. Investing in these machines will improve productivity, package quality, and reduce downtime.

They’re a great option for the expanding beverage industry and those looking to provide an on-the-go frozen treat to consumers.

Cycles Per Minute Max.

Sachets Per Min Max.

Max. Bag Width

Max. No of Lanes

4 lane Popsicle Sachet Bagger

minute max.

bag width

bag length

Frequently Asked Questions

How are Popsicles packed?

Liquid-filled popsicles, commonly known as freeze pops, ice pops, or freezies, are packed using automated vertical form-fill-seal (VFFS) machines. These machines ensure hygienic, efficient, and high-speed packaging, keeping the product fresh and safe for consumers.

Packing Process for Liquid-Filled Popsicles:

Liquid Filling: The flavored liquid mixture is precisely dispensed into flexible plastic sachets through piston, auger, or volumetric filling systems.

Sealing: The servo-driven sealing system ensures consistent package quality and leak-proof sealing while the product remains in its unfrozen state.

Batch Coding & Labeling: Optional inline thermal printers allow for lot codes, expiration dates, and branding information to be printed on each package.

Freezing & Storage: Once sealed, the sachets are stored and frozen before distribution to retailers.

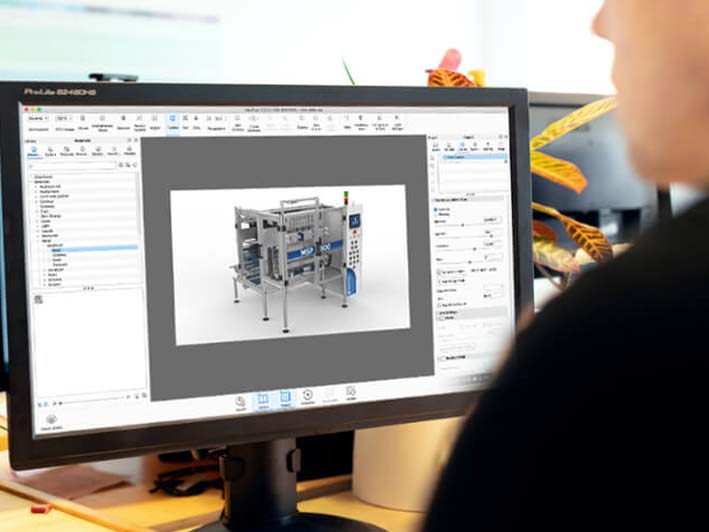

Unified Flex specializes in high-performance liquid popsicle packaging machines, including the MSB-406 Multilane Popsicle Sachet Bagger, designed for efficient, accurate, and high-speed production.

Looking for the best liquid-filled popsicle packaging solution? Contact Unified Flex today!

What types of frozen treats can popsicle packaging machines pack?

Unified Flex specializes in packaging liquid-filled frozen treats, ensuring hygienic, efficient, and high-speed production. Our machines are designed for precise filling and secure sealing of various frozen products, including:

1. Freeze Pops & Ice Pops

- Liquid-filled freeze pops (also known as ice pops or freezies) are sealed while in liquid form and then frozen.

- The form-fill-seal (FFS) process ensures accurate filling and leak-proof sealing before freezing.

2. Tube & Stick Frozen Beverages

- Machines package juice-based frozen treats into tube-style pouches, which are frozen before distribution.

- Perfect for sports drinks, electrolyte ice, and flavored water pops.

3. Yogurt & Dairy-Based Freeze Pops

- Designed for yogurt-based frozen treats, which are filled and sealed in liquid form before freezing.

- Suitable for kefir pops, smoothie pops, and dairy-based ice treats.

Unified Flex offers liquid popsicle packaging machines optimized for hygienic, precise, and high-speed operations, ensuring perfectly sealed frozen treats for retail and wholesale distribution.

Need a tailored frozen treat packaging solution? Contact Unified Flex today!

What materials (plastic, foil, eco-friendly) can be used for popsicle packaging?

Popsicle packaging requires flexible, durable, and food-safe materials to maintain freshness, prevent leaks, and withstand freezing temperatures. The most common materials used for liquid-filled freeze-pop packaging include:

1. Plastic Film Packaging (Most Common)

- Polyethylene (PE) & Polypropylene (PP): Widely used for freeze pops and ice pops due to their flexibility, heat-seal compatibility, and food-grade safety.

- Multi-layer Plastic Films: Provide extra strength, puncture resistance, and barrier protection to prevent leaks.

2. Foil & Laminated Packaging

- Plastic-Aluminum Laminates: Offer higher protection against moisture and oxygen, extending shelf life.

- Metalized Films: Used for specialty frozen products requiring moisture and oxygen barrier protection.

3. Eco-Friendly & Sustainable Packaging

- Recycled Polyethylene Films (rPE): Made from post-consumer recycled plastic, reducing plastic waste while maintaining durability and seal strength.

Unified Flex’s popsicle packaging machines are designed to handle a variety of flexible packaging materials, ensuring efficient sealing, durability, and food safety. Whether you need traditional plastic films or sustainable options, we provide customized solutions to meet your packaging goals.

Looking for the right popsicle packaging material? Contact Unified Flex today!

Can Popsicle Packaging machines handle custom packaging designs, such as branded wrappers?

Yes! Popsicle packaging machines can accommodate custom packaging designs, including branded wrappers, printed films, and unique packaging styles. These machines support various customization options to enhance brand visibility and product appeal.

1. Pre-Printed Flexible Films

- Machines can use pre-printed, heat-sealable plastic or laminated films featuring full-color branding, logos, and product details.

- Supports high-resolution graphics and vibrant colors for eye-catching designs.

2. Digital & Rotogravure Printing Compatibility

- Works with rotogravure, flexographic, and digital printing techniques, enabling detailed, high-quality branding for both high-volume and short-run packaging.

- Allows for custom designs for seasonal, promotional, or limited-edition packaging.

3. Custom Wrappers & Specialty Packaging

- Supports clear, opaque, and metallic-finish wrappers, including select eco-friendly and biodegradable film options compatible with sealing requirements.

- Offers flexibility in material selection to align with sustainability initiatives and premium packaging needs.

4. Lot Coding & Date Printing

- Integrated thermal and inkjet printers ensure precise lot coding, expiration dates, and batch number printing for regulatory compliance.

- Customizable placement for barcodes, QR codes, and traceability markings.

Get Custom Popsicle Packaging with Unified Flex

Unified Flex’s popsicle packaging machines are designed to handle custom-printed films and branded wrappers, ensuring high-quality, professional packaging that aligns with your brand identity.

Looking for a popsicle packaging solution with custom branding? Contact Unified Flex today!

Can popsicle packaging machines include tamper-proof seals and tear notches for safety and convenience?

Yes! Popsicle packaging machines can be equipped with tamper-proof seals and tear notches to enhance product safety and consumer convenience. These features ensure secure packaging while making it easy for customers to open and enjoy their treats.

1. Tamper-Proof Seals for Safety

- Heat Sealing: Creates an airtight, leak-proof seal that prevents contamination and maintains freshness.

- Perforated Seals: Adds visible tamper evidence, ensuring consumers that the product is fresh and untouched.

- No-Bag, No-Fill Technology: Ensures only properly sealed pouches are filled, preventing spills and packaging errors.

2. Tear Notches for Easy Opening

- Pre-Cut Tear Notches: Allows for effortless opening without scissors.

- Directional Tear Features: Ensures clean and consistent tearing along a designated path.

- Resealable Zippers (Optional): Common for multi-serve frozen treats, though less typical for single-use popsicle packaging.

Unified Flex offers popsicle packaging machines with built-in tamper-proof sealing and tear-notch features, ensuring safe, user-friendly, and efficient packaging for liquid-filled freeze pops.

Need a secure and convenient popsicle packaging solution? Contact Unified Flex today!

How do popsicle packaging machines ensure airtight sealing for optimal freshness?

Airtight sealing is a critical factor in popsicle packaging, helping maintain product freshness, prevent leaks, protect against freezer burn, and ensure food safety. The sealing process relies on precise heat application, controlled pressure, and high-quality packaging materials to create strong, leak-proof seals that keep products secure. Popsicle packaging machines use digital controls, pneumatic vertical sealing jaws, and servo-driven horizontal sealing jaws to guarantee consistent, high-speed, and reliable performance.

Sealing Technology in Unified Flex Machines

Unified Flex’s Popsicle Sachet Bagger MSB-406 Multilane is designed with advanced sealing technology to provide airtight, durable, and efficient packaging solutions. This machine ensures leak-proof sealing and maintains product integrity through the following features:

1. Heat Sealing with Pneumatic & Servo Control

- Servo-driven horizontal and pneumatic vertical sealing jaws apply precise heat and pressure to create strong, airtight seals.

- Intermittent motion film pull ensures consistent sealing while preventing material wrinkles.

2. Consistent Seal Quality with Digital Control

- Omron Sysmac digital controllers synchronize the form, fill, and seal process, ensuring uniform, high-speed results.

- Temperature control systems maintain consistent heat application, ensuring airtight sealing without overheating or burning the packaging.

- Pneumatic vertical sealing jaws provide even pressure distribution across the seal area.

3. Durable and Hygienic Packaging Materials

- Compatible with various flexible packaging films, including polyethylene (PE) and laminated barrier films, which help maintain product integrity.

- Corrosion-resistant stainless-steel components ensure the sealing process meets food safety standards.

4. High-Speed and Reliable Sealing Performance

- Supports up to 4-lane configurations, producing up to 200 sachets per minute, depending on pouch size and film properties.

- Automatic film unwind systems and spring-loaded rotary slitting blades help maintain continuous, precise sealing.

Unified Flex provides high-speed popsicle packaging solutions, including the MSB-406 Multilane Popsicle Sachet Bagger, designed to deliver airtight, durable, and leak-proof sealing, ensuring maximum freshness and product integrity.

Looking for a reliable popsicle packaging solution? Contact Unified Flex today!

Popsicle Packaging Machines for Freshness from Factory to Freezer

The happiness of enjoying a popsicle is truly everlasting. From kids racing to grab freeze pops on a hot summer day to adults reaching for a nostalgic ice pop straight from the freezer, these frozen treats have become more than just snacks; they’re a craze that continues to grow worldwide. But behind every perfectly sealed, ready-to-freeze popsicle is a process that requires precision, speed, and consistency.

That’s where a custom popsicle packaging machine from Unified Flex steps in. Built to handle liquid-filled popsicles, ice pops, and freezies with accuracy, these machines ensure every sachet is hygienically packed, leak-proof, and shelf-ready. For businesses, this translates into more productivity, less downtime, and packaging that not only meets but exceeds industry standards, keeping up with the booming demand for on-the-go frozen treats.

What Are Popsicle Packaging Machines?

A popsicle packaging machine is an automated vertical form-fill-seal (VFFS) system built for liquid-filled sachets. These sachets are sealed while the product is still in liquid form and then frozen, ensuring fresh, safe, and easy-to-enjoy frozen treats.

From flavored water pops and energy-boosting electrolyte pops to yogurt-based smoothie pops, our machines guarantee consistent portioning, hygienic sealing, and strong packaging that withstands freezing temperatures.

At Unified Flex, we design popsicle packaging machines that are efficient, versatile, and easy to integrate into your production line.

What Packaging Speeds and Sizes Can You Expect?

When it comes to popsicle production, speed and accuracy are non-negotiable. Unified Flex’s machines deliver exactly that:

- Up to 200 sachets per minute (using 4 lanes)

- 4-inch maximum bag width

- 12-inch maximum web width

Where Can You Use Our Popsicle Packaging Machines?

Our machines are designed for flexibility across industries, making them ideal for a variety of frozen treats:

- Beverage Industry: Freeze pops, ice pops, sports drink pops, flavored water pops

- Health & Wellness: Energy pops, vitamin-fortified frozen drinks, herbal pops

- Dairy & Yogurt-Based Treats: Smoothie pops, kefir pops, probiotic pops

With our machines, you can package and seal efficiently, while ensuring every product is fresh, safe, and consumer-ready.

Are You Facing These Common Packaging Challenges?

Many businesses in the frozen food and beverage sector struggle with:

- Leakage issues due to weak or inconsistent seals

- High downtime from machine stoppages or adjustments

- Inaccurate filling leading to product waste

- Packaging inconsistency in size or seal quality

- Slow production speeds limiting output capacity

- High material waste from film misalignment or errors

- Hygiene concerns during liquid filling and sealing

A Complete Solution for Popsicle Packaging

Unified Flex popsicle packaging machines are engineered to solve these challenges.

4 Lane Popsicle Sachet Bagger

The 4 Lane Popsicle Sachet Bagger delivers reliable, high-speed packaging for liquid-filled popsicles, freeze pops, and ice pops. Capable of producing up to 200 sachets per minute with 3- or 4-sided seals, it handles bags up to 12 inches long and 4 inches wide.

Ideal For:

- Liquid-filled freeze pops & ice pops

- Yogurt & dairy-based frozen treats

- Juice-based tubes & stick pops

- Specialty frozen beverages

Specifications:

| Model | Max Output | Max Stick Pack Width | Max Stick Pack Length | |

| 4 Lane Popsicle Sachet Bagger | 200 sachets per minute | 4″ (inches) | 12″ (inches) |

How Popsicles Are Packed

If you’ve ever wondered how liquid popsicles are turned into those neat, leak-proof sachets, here’s a quick breakdown:

- Liquid Filling: The flavored liquid mix (juice, yogurt, electrolyte drink, etc.) is dispensed with precision using piston, auger, or volumetric filling systems.

- Sealing: The sachets are sealed while still in liquid form using servo-driven sealing jaws that ensure consistency and prevent leaks.

- Batch Coding & Labeling: Thermal printers can add expiration dates, lot codes, and branding directly to the film.

- Freezing & Storage: Once sealed, sachets are frozen before being shipped to retailers.

What Materials Can Be Used for Popsicle Packaging?

Packaging materials play a huge role in maintaining product freshness and safety. A liquid popsicle packaging machine from Unified Flex is designed to work with a variety of films:

Plastic Film Packaging (Most Common)

- Polyethylene (PE) & Polypropylene (PP) – Flexible, heat-sealable, and food-safe.

- Multi-layer films for added strength and leak prevention.

Foil & Laminated Packaging

- Plastic-aluminum laminates provide moisture and oxygen barriers.

- Metalized films for extended shelf life and specialty products.

Eco-Friendly Options

- Recycled Polyethylene Films (rPE) for sustainability.

- Biodegradable or compostable films compatible with sealing technology.

- ASTM D6400 certified packaging materials for compostable options.

- PE-based films compatible with Vertobagger Falcon for eco-friendly production.

Need a Smarter Way to Package Popsicles?

Not sure which popsicle wrapping machine is right for you? Let’s discuss your production scale, budget, and product type. If you’re a plant engineer setting up a beverage line, a manager scaling up frozen treat production, or a brand owner launching a new product, Unified Flex Popsicle Packaging Machines are built to fuel your success.

Let’s connect! We’ll recommend the best-fit packaging system for your popsicle products.