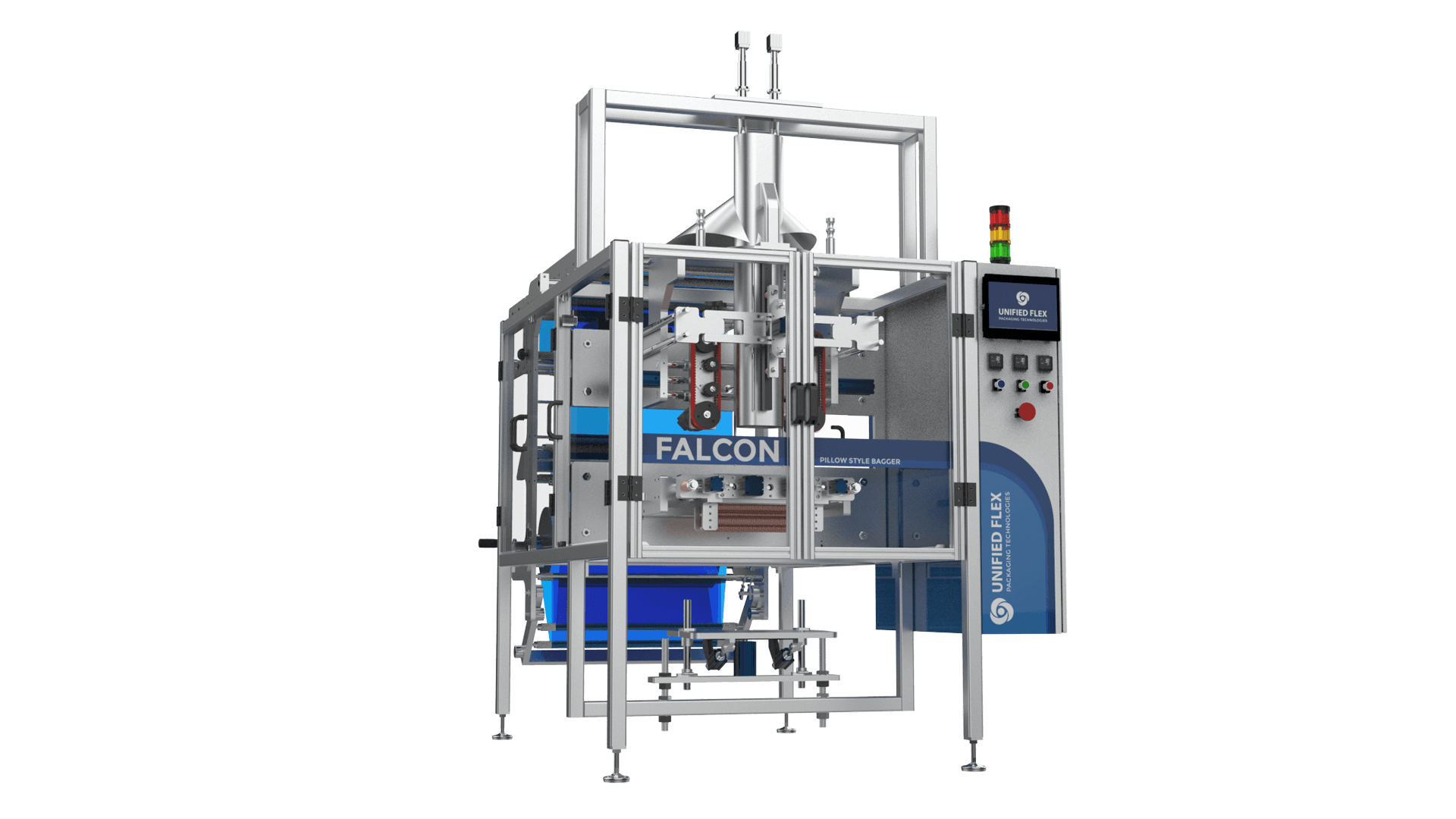

Enhance your brand’s shelf appeal and the quality of your product with our premium pillow bag with side gussets or side gusset pouch. These bags offer the familiar convenience of a pillow bag with the additional benefit of expandable width. They are perfect for a wide variety of products that can’t fit in a classic pillow bag while maintaining a professional sleek look.

These gussets also enable your product to stand out on the shelf with distinct brand differentiation. Additionally, the collapsable nature allows for different display options- you can either present your product vertically for maximum impact or lay it horizontally to save space. Whether you want to pack dairy, meat, cheese, coffee, produce, and more, these bags can handle them all.