Food safety in meat, poultry, and fish packaging is critical to prevent contamination, extend shelf life, and maintain product integrity. Automated packaging machines play a key role in ensuring safe handling and packaging of perishable products.

How Unified Flex Machines Enhance Food Safety

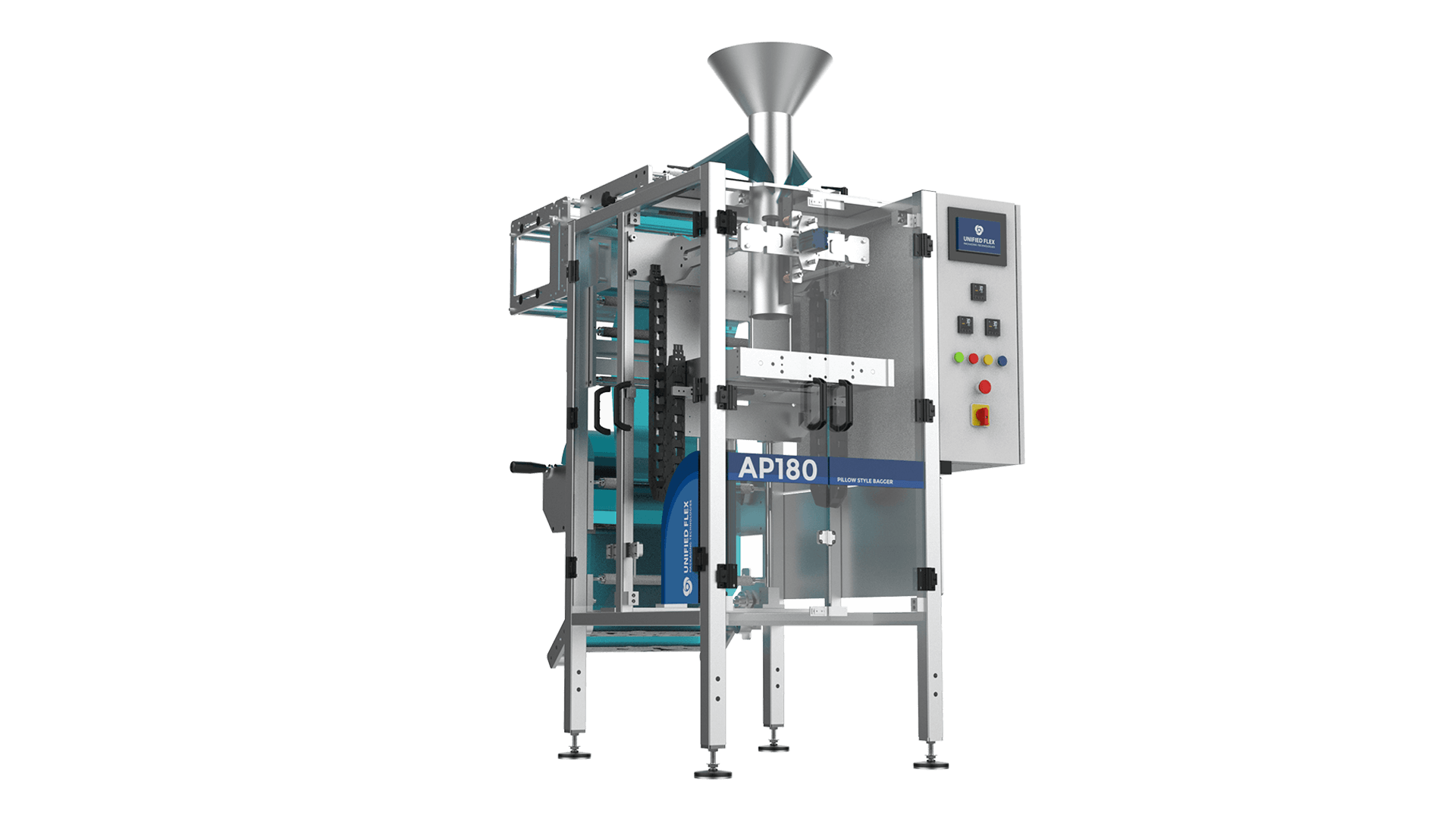

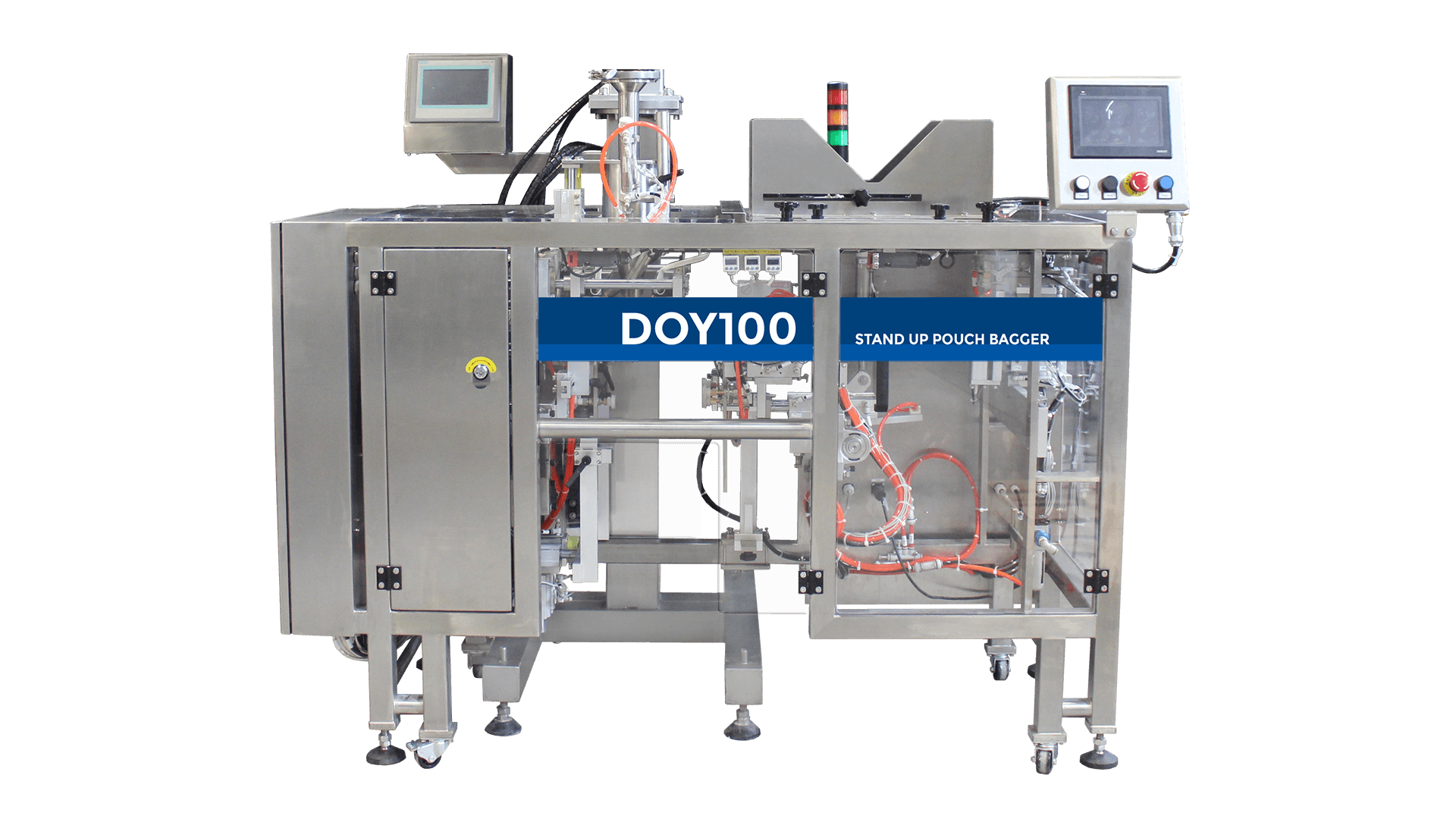

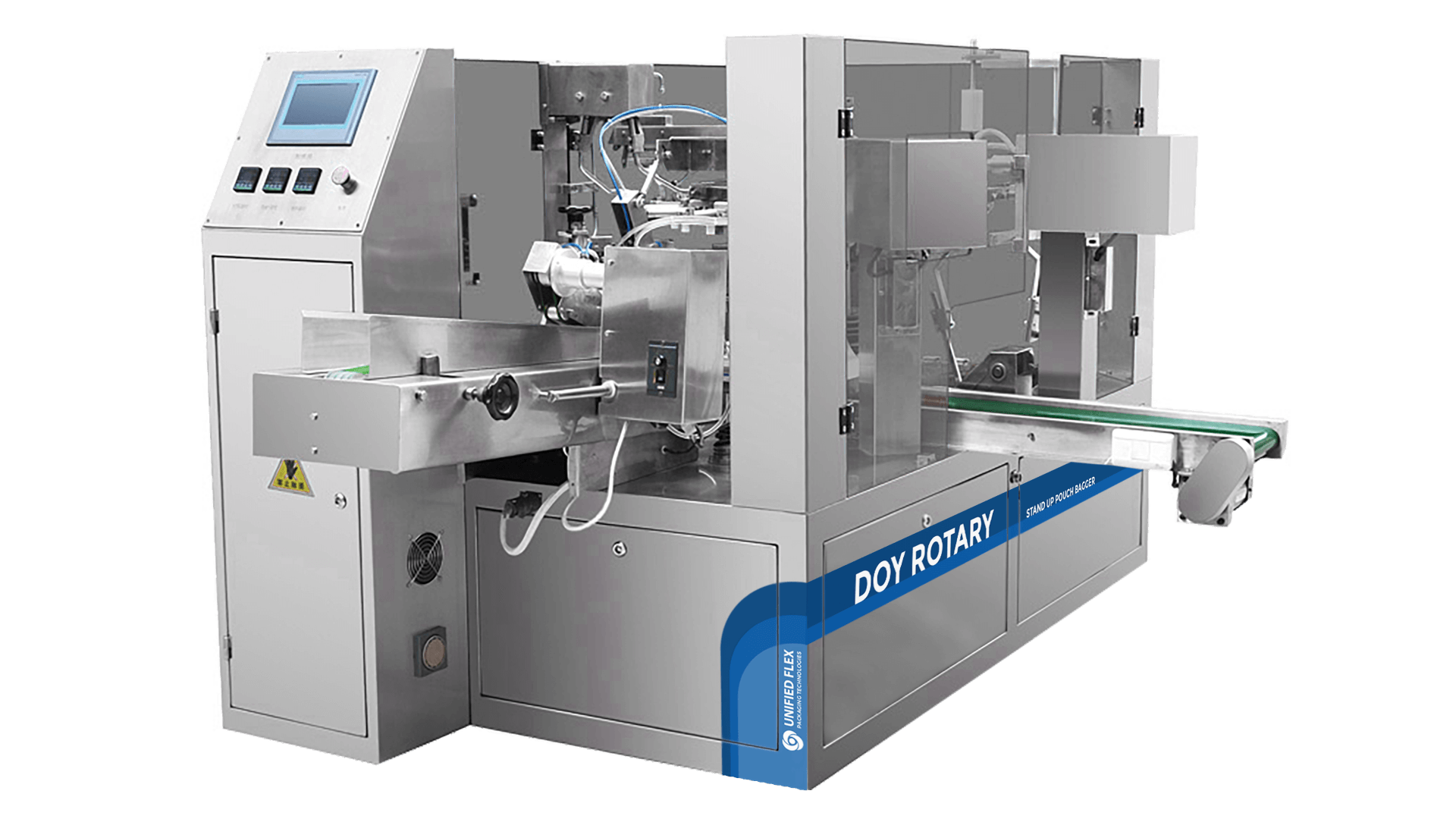

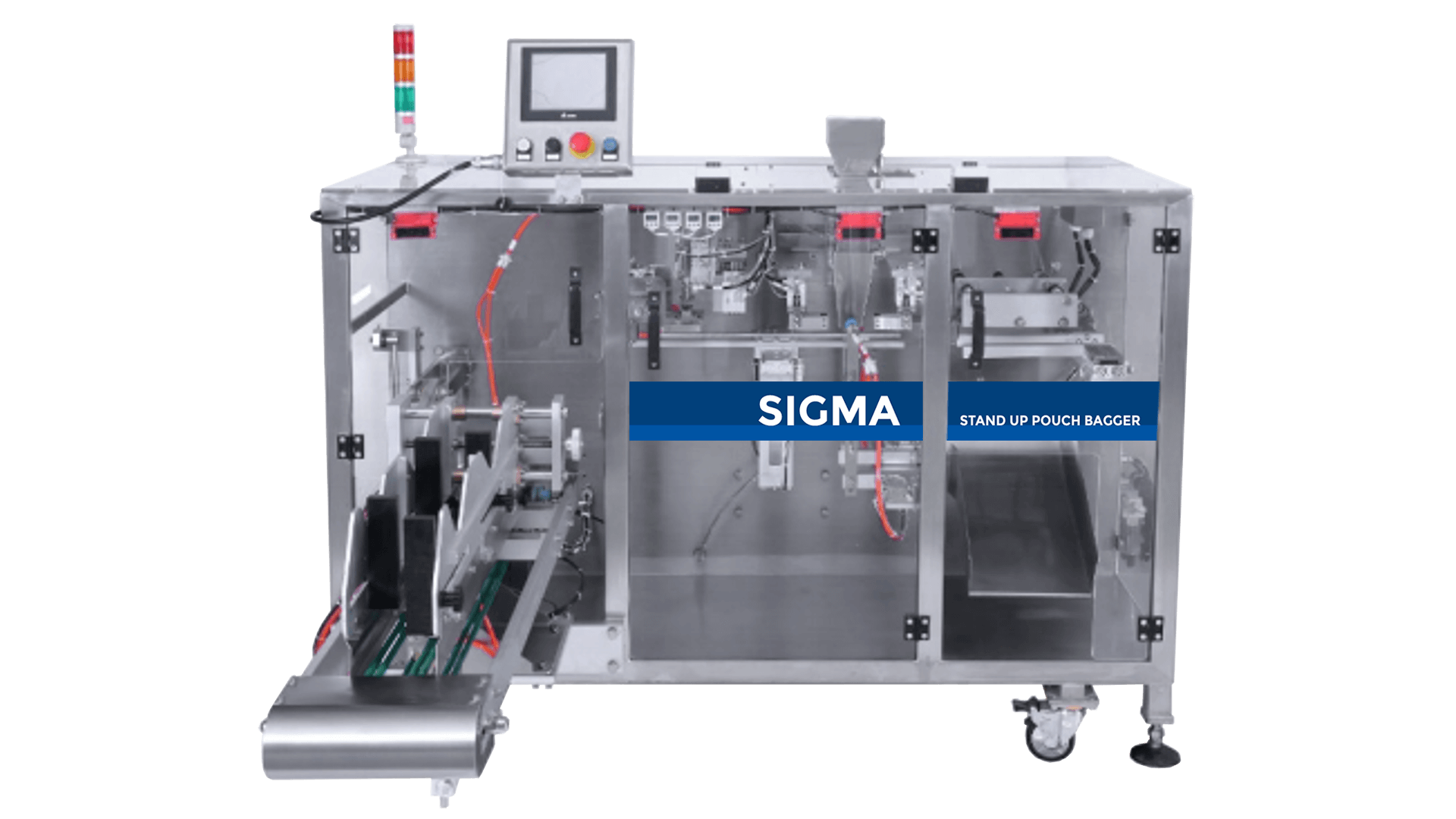

Unified Flex offers packaging machines designed to meet the highest food safety standards. Here’s how they improve food safety:

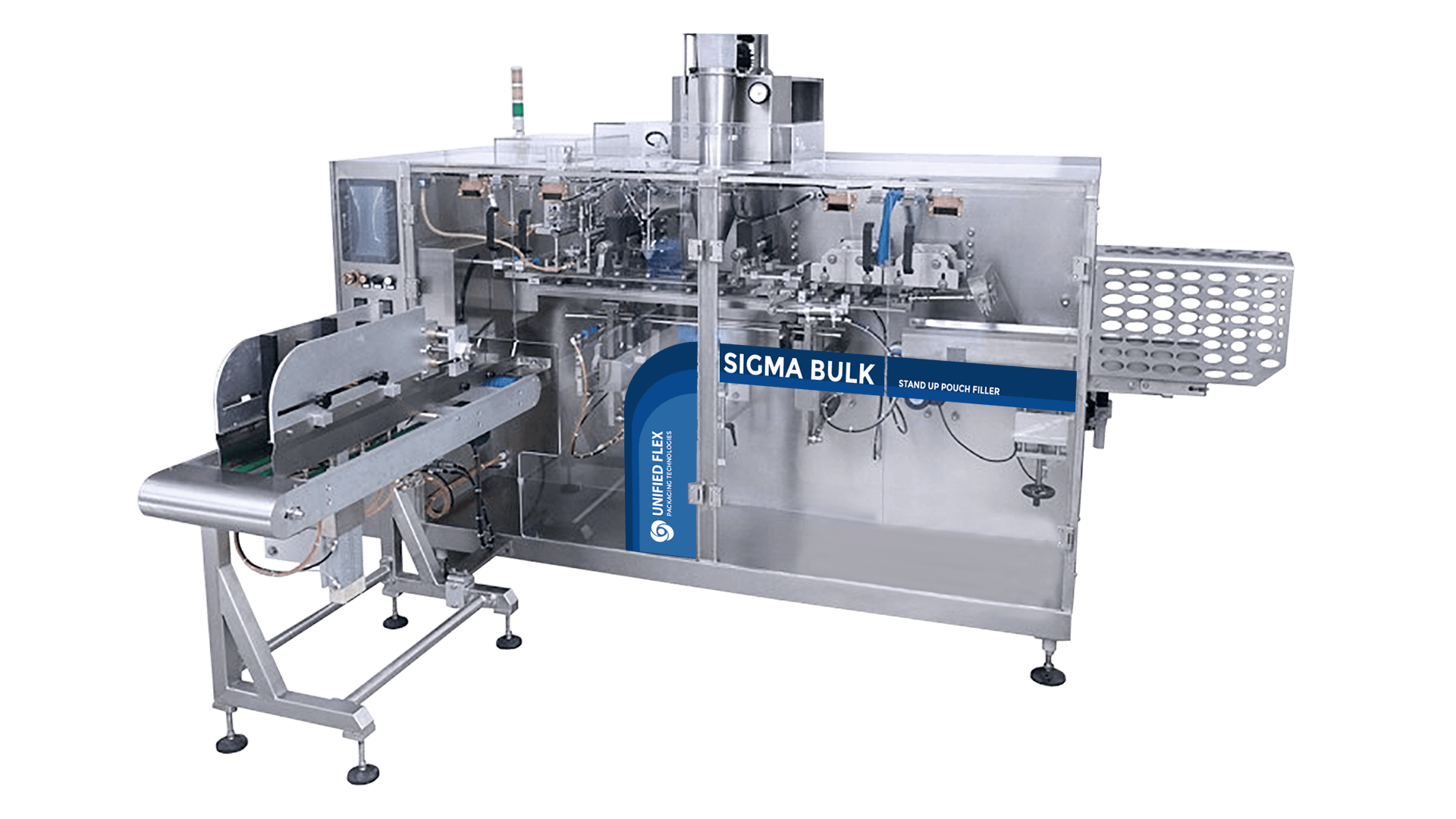

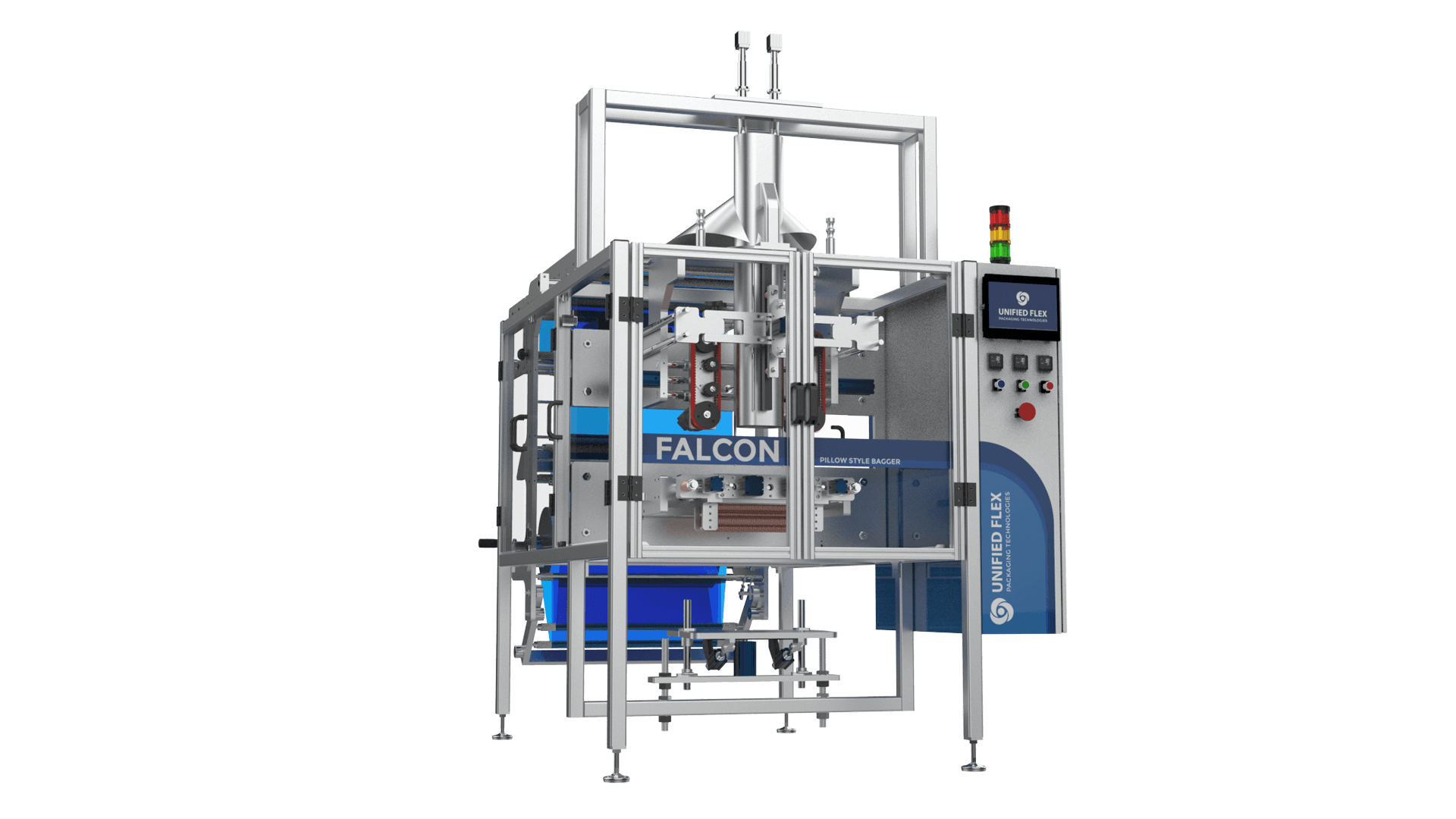

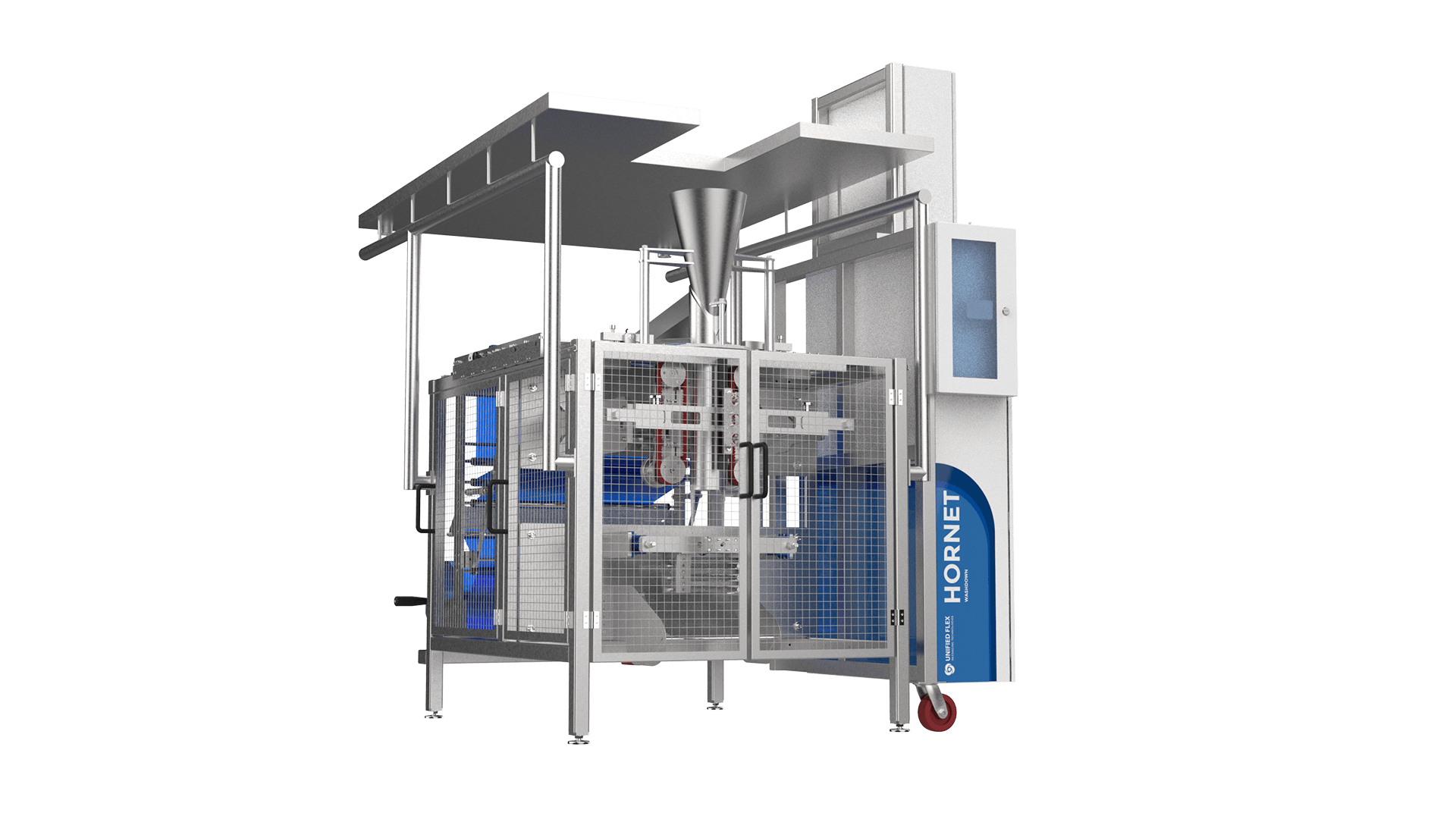

Minimizes Human Contact: Our automated packaging process reduces manual handling, lowering the risk of cross-contamination.

Hygienic Stainless Steel Construction: Machines are built with 304 stainless steel, which is easy to clean and resists bacterial buildup.

Secure Sealing Technology: Ensures airtight, leak-proof packaging to protect against contaminants and extend shelf life.

Compatible with Vacuum and MAP Packaging: Reduces oxygen exposure to slow bacterial growth and prevent spoilage.

High-Precision Weighing & Filling: Works seamlessly with multi-head weighers, auger fillers, and piston fillers, ensuring accurate portioning and reducing product waste.

Washdown & Sanitary Design Options: Models like the Vertobagger Hornet Washdown are built for environments requiring frequent sanitation.

Get in Touch

Looking for a food-safe packaging solution for meat, poultry, or fish? Contact Unified Flex today to explore our VFFS packaging machines designed for hygienic, efficient, and secure packaging!