When choosing a rice packing machine, it’s important to consider features that enhance efficiency, accuracy, and durability. A well-designed machine ensures consistent packaging, preserves freshness, and optimizes production.

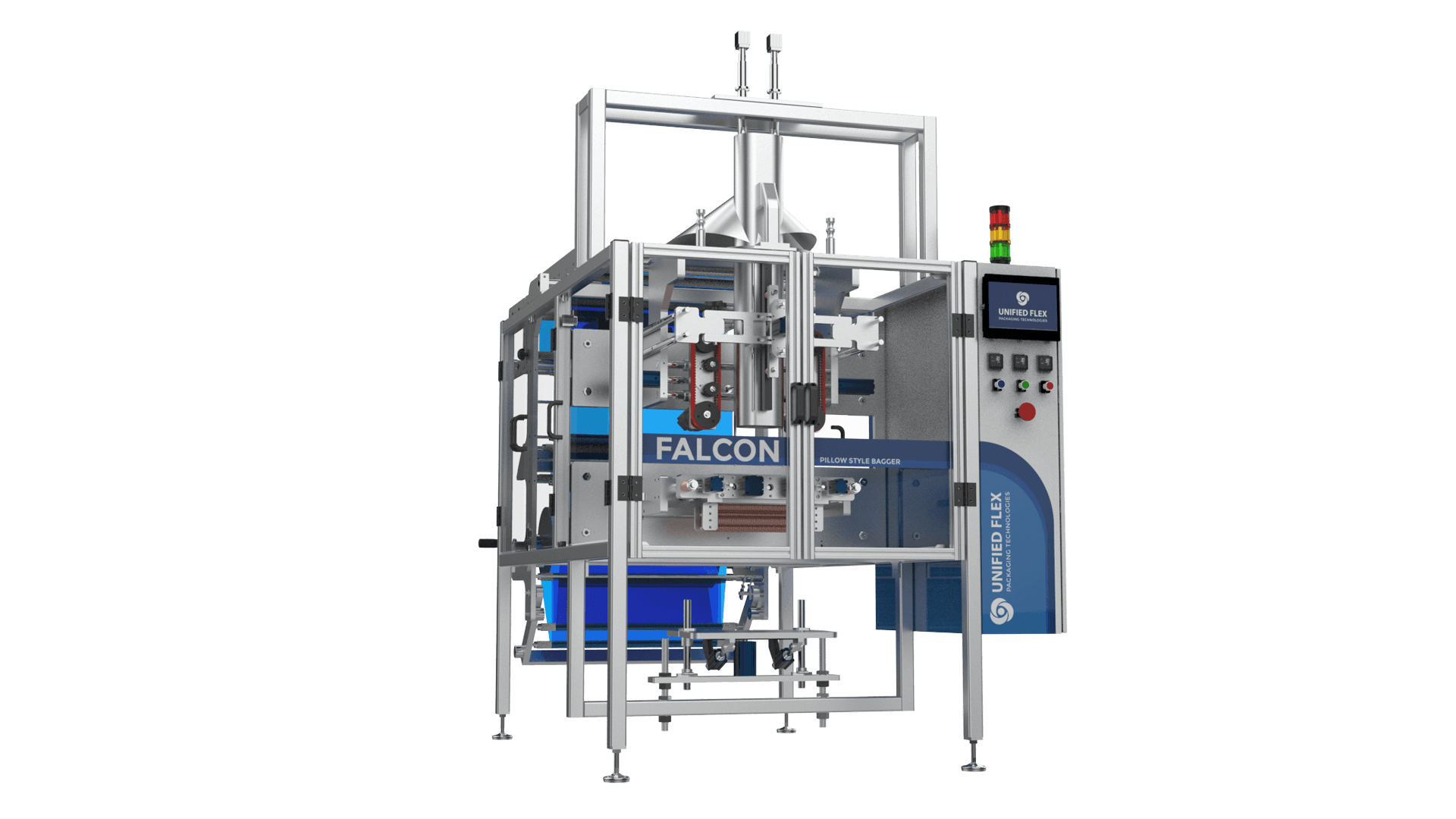

1. Speed & Performance: A rice packing machine should operate at high speeds while maintaining precision. Machines with servo-controlled film pulling and efficient sealing systems help achieve faster cycles without compromising quality.

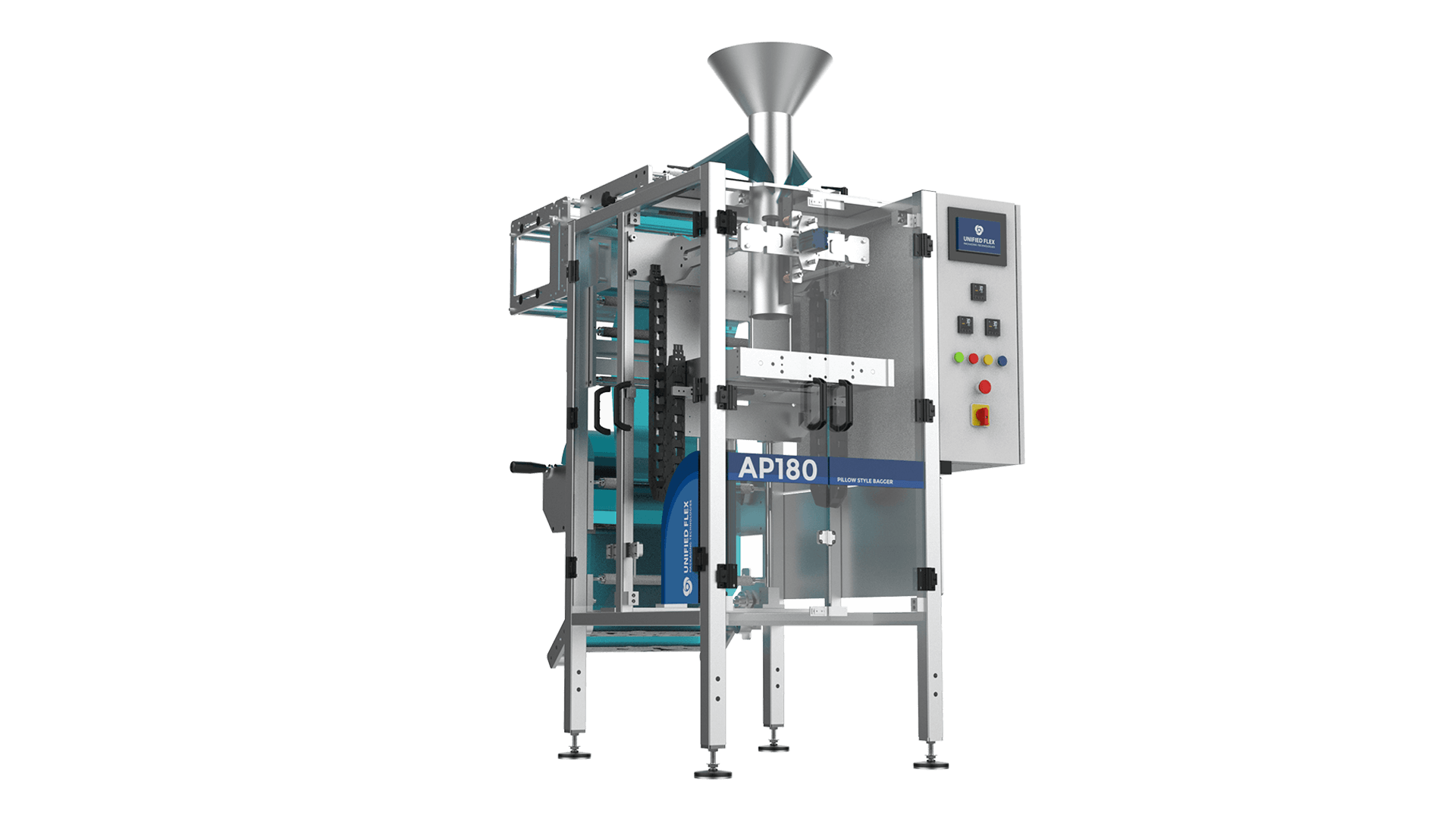

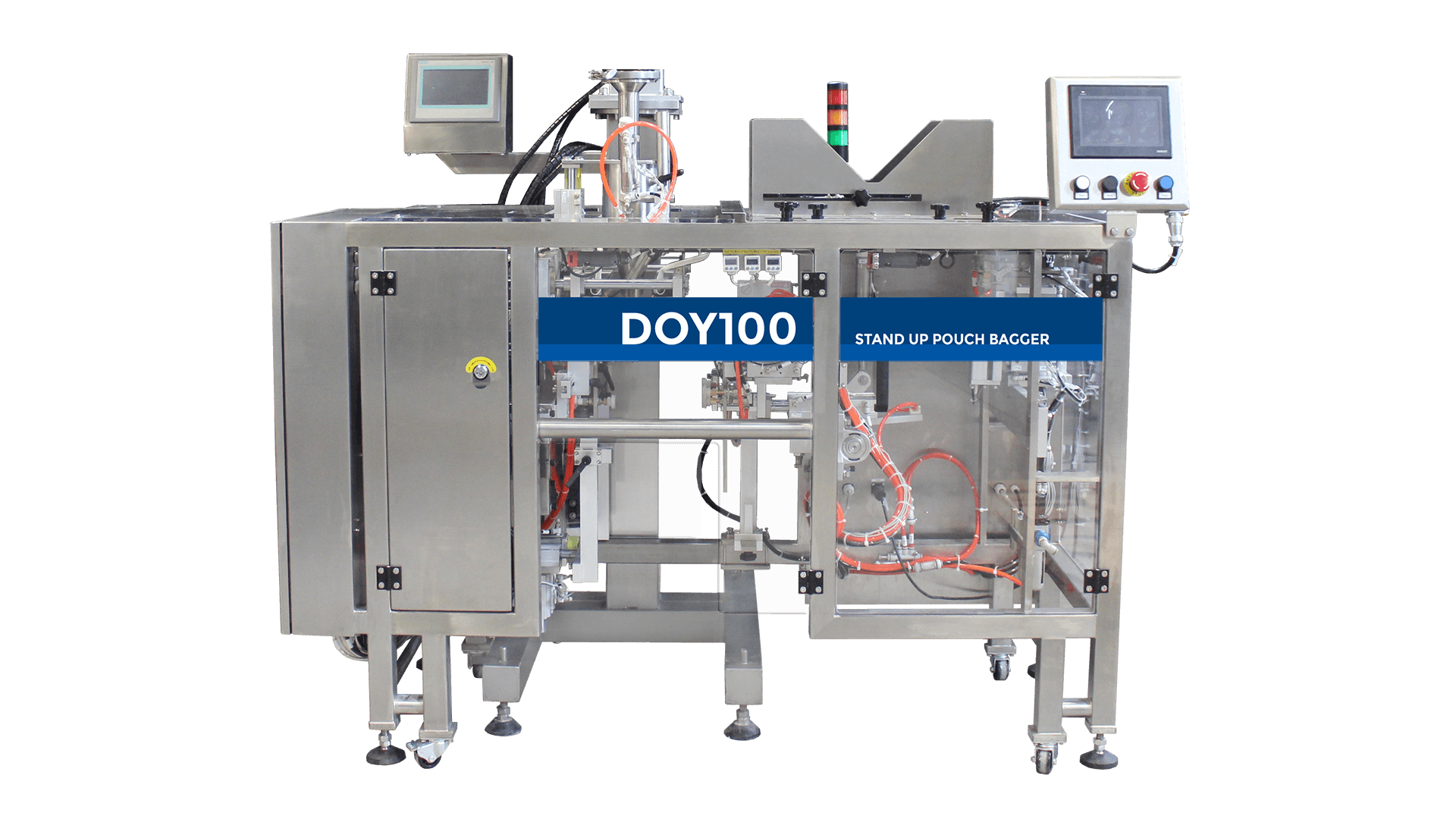

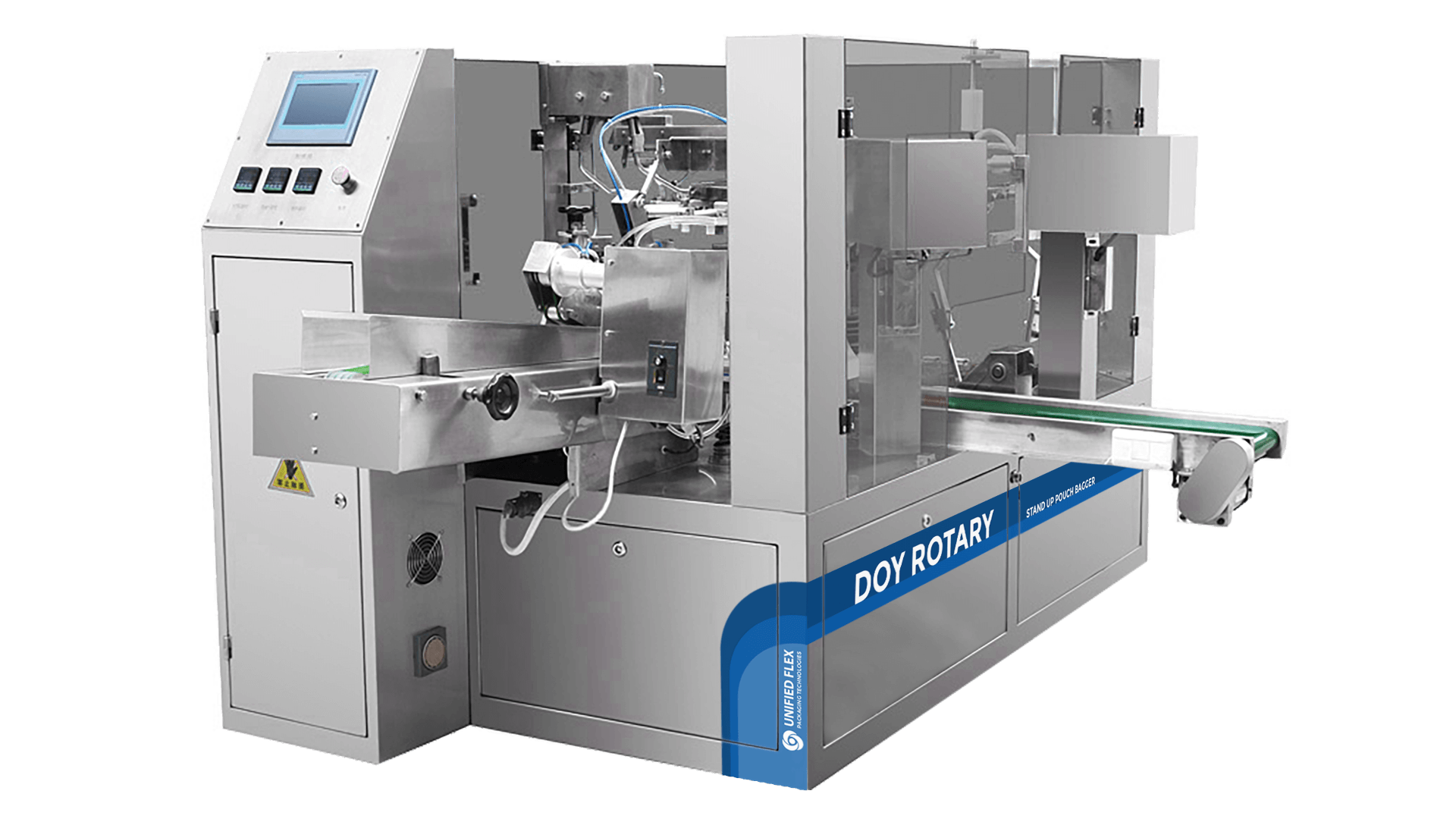

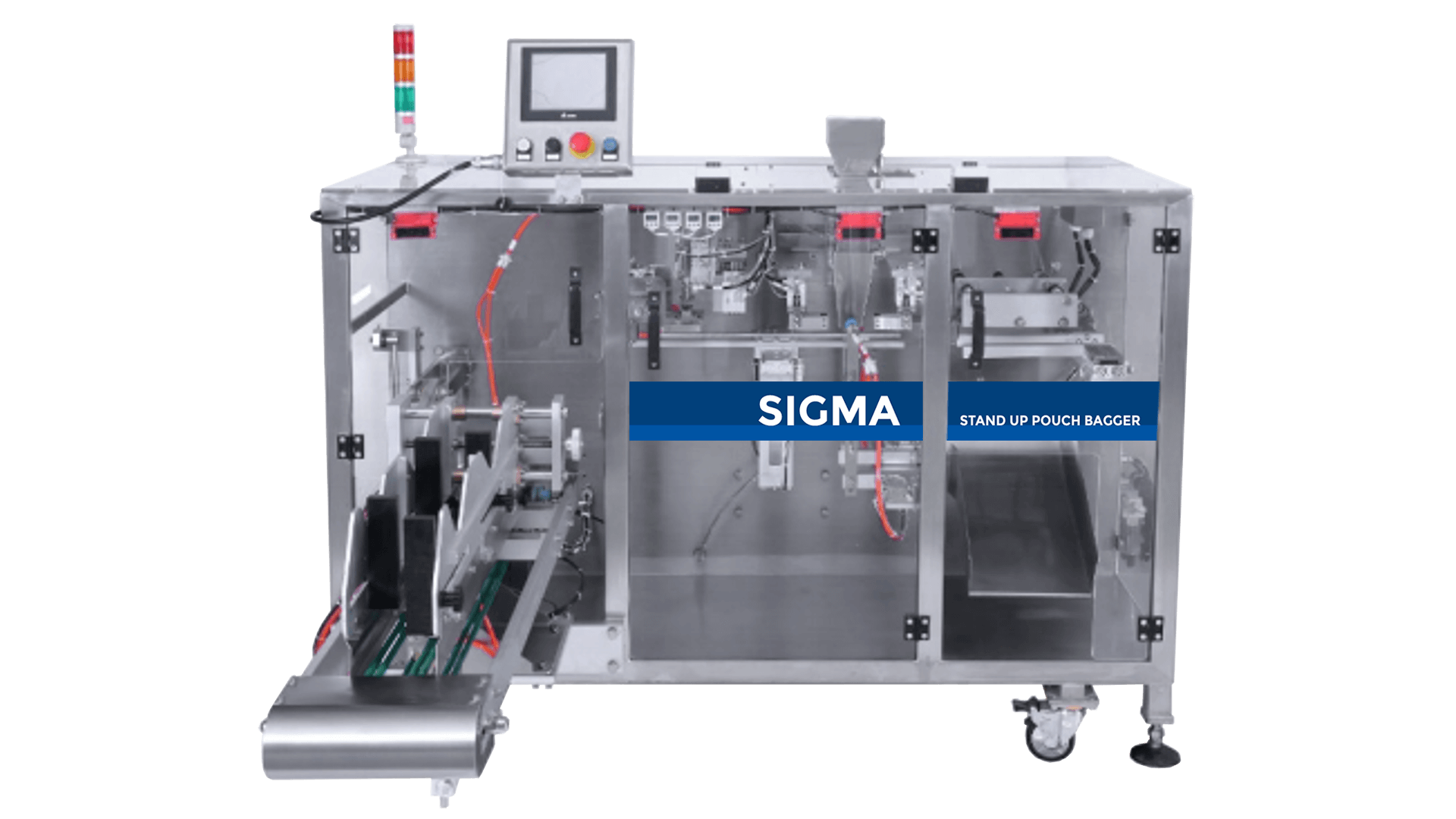

2. Bag Versatility: A rice packaging machine should support multiple bag styles to meet diverse market needs. Choose a machine that provides this versatility.

3. Strong Sealing & Packaging Integrity: Rice requires secure, airtight sealing to prevent moisture contamination. Machines with heat sealing or ultrasonic sealing ensure durability and freshness.

4.Dust & Moisture Control: Since rice packaging generates fine dust, dust extraction systems and moisture-resistant components help maintain cleanliness and efficiency.

5. Quick Changeovers for Different Bag Sizes: For flexible production, a machine should allow easy and tool-free switching between bag sizes to maximize efficiency.

6. User-Friendly Controls & Automation: A modern rice packing machine should feature an intuitive touchscreen HMI, PLC controls, and automatic adjustments for ease of operation.

7. Hygienic & Durable Construction: A machine built with 304 stainless steel ensures compliance with food safety regulations, easy cleaning, and long-lasting durability.

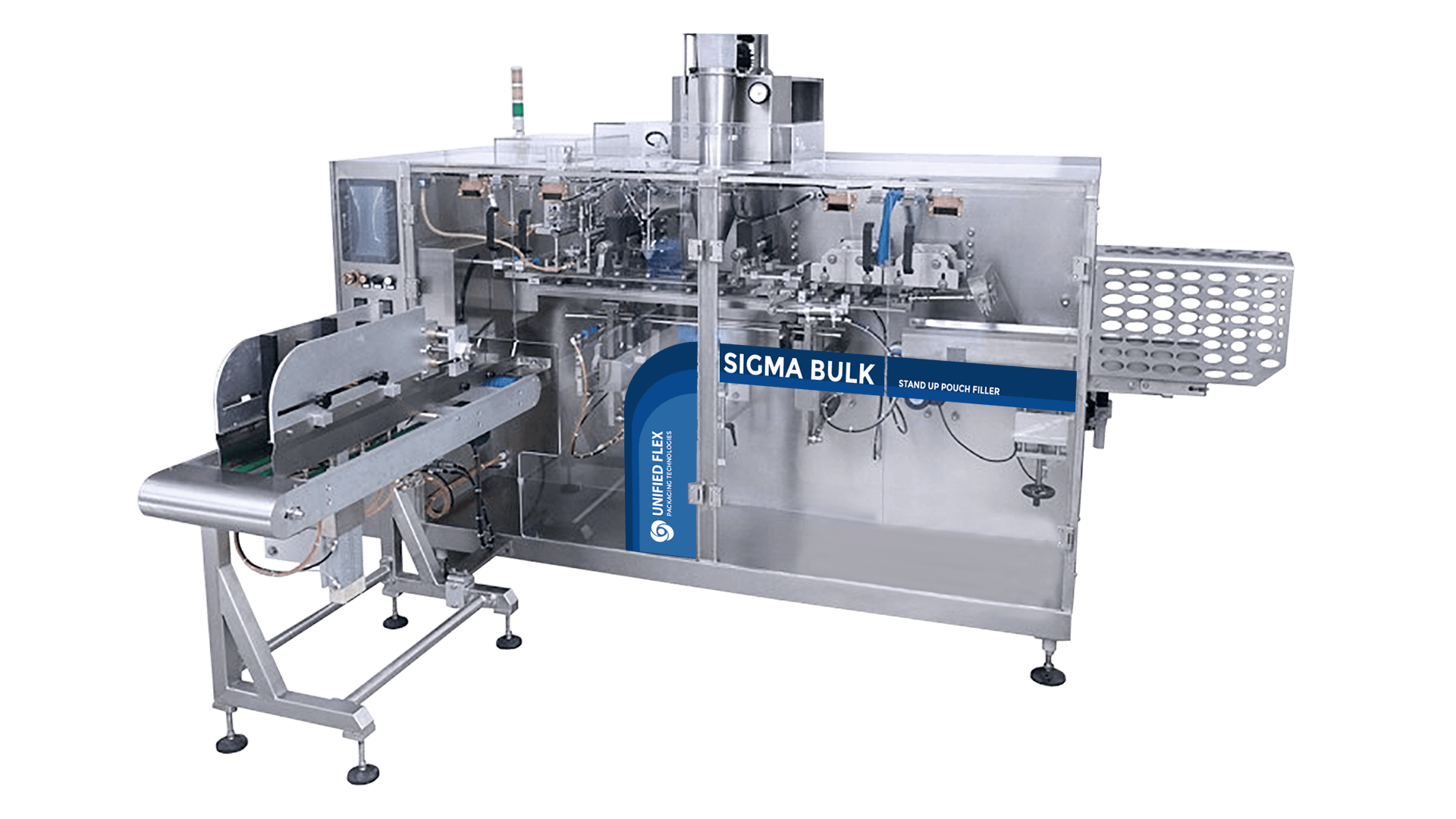

8. Integration with Conveyors & Takeaway Systems: A well-designed machine should support exit conveyors, bag unloaders, and automatic collection systems to streamline packaging operations.

9. Low Maintenance & Easy Spare Parts Availability: Opt for a machine designed with non-proprietary spare parts to ensure easy replacements and minimal downtime.

Looking for a rice packing machine? Unified Flex offers customized solutions to meet your packaging requirements. To learn more, call us at 1-866-369-4181 or get a free consultation today!