VERTICAL FORM FILL SEAL MACHINES

Packaging Solutions Built Around Your Product

Unified Flex designs packaging solutions around your product’s unique behavior. From free-flowing liquids to granular and sticky powders, each material requires specific handling and sealing conditions. Our systems ensure every package is consistent, dependable, and ready for the market.

Our vertical form fill seal (VFFS) machines are engineered to fit your product, your plant, and your process. Every design reflects our principles of being simple, reliable, and robust, because packaging should never be the bottleneck in your operation.

Proven Across Diverse Product Behaviors

Every product brings unique packaging challenges, shaped by flow, viscosity, or particle structure. Unified Flex has delivered solutions across 20+ industries, from food, beverage, and nutraceuticals to pharmaceuticals, pet food, personal care, and industrial applications. This breadth of experience means we’ve solved challenges like yours before, and we know how to engineer packaging systems that deliver consistent, efficient, and reliable performance.

Applications That Speak for Themselves

Viscous or Semi-Viscous Liquids

Perfectly packed popsicles, a testament to our turnkey packaging expertise for viscous products.

Consistent gel filling and robust sealing — showcasing our VFFS expertise in handling high-viscosity products with precision and reliability.

Granular & Powder Products

Accurately filled and reliably sealed , a demonstration of our servo-driven pouch packaging machine for granular and powder products.

Accurate dosing and precise sealing — delivering clean, consistent stick packs

Solids

Consistent pillow bag formation and strong sealing — showcasing our expertise in packaging solid products with precision and reliability.

Stainless steel washdown design with servo-driven control — engineered for hygienic operation and consistent bagging performance in solid product applications.

Packaging Challenges We Solve

Every manufacturer faces recurring hurdles that drain time, waste product, and erode confidence. We address these challenges head-on, turning them into dependable outcomes

- Frequent changeovers — switching SKUs or bag sizes without losing hours of production

- Training new operators — intuitive controls and simple setups that shorten the learning curve

- Downtime risk — keeping uptime high with precise, durable parts that minimize rework

- Seal integrity — consistent, high-quality seals that prevent leaks, recalls, and unhappy customers

- Film tracking issues — reliable film handling for clean, straight packages every run

- Hygiene requirements — washdown-friendly stainless steel designs that reduce contamination risk

- Maintenance complexity — built-in diagnostics and robust frames for faster troubleshooting and less upkeep

Our role is simple: remove these frustrations so your operation runs smoothly, safely, and profitably.

Packaging Challenges We Solve

Every feature on a Unified Flex machine exists to remove complexity and build confidence in your packaging line.

Machine Features

What it Means For You

Our Process:

Structured, Transparent, Reliable

When you work with Unified Flex, you get more than a machine. You get a process that minimizes risk:

- Understand your product & goals

- Engineer the right design for your plant requirements

- Test every system in-house before shipment

- Factory Acceptance Test (FAT) with your team

- Install, train, and support with North American service & parts erican service & parts

Why Manufacturers Choose Unified Flex

- North American-built machines - Fast access to parts and support.

- Process-driven engineering - Consistency, not improvisation.

- Proven experience across industries - Food, pharma, medical, industrial.

- Focused on reliability - No lofty promises, just dependable results.

- Partnership approach - We align with your long-term goals

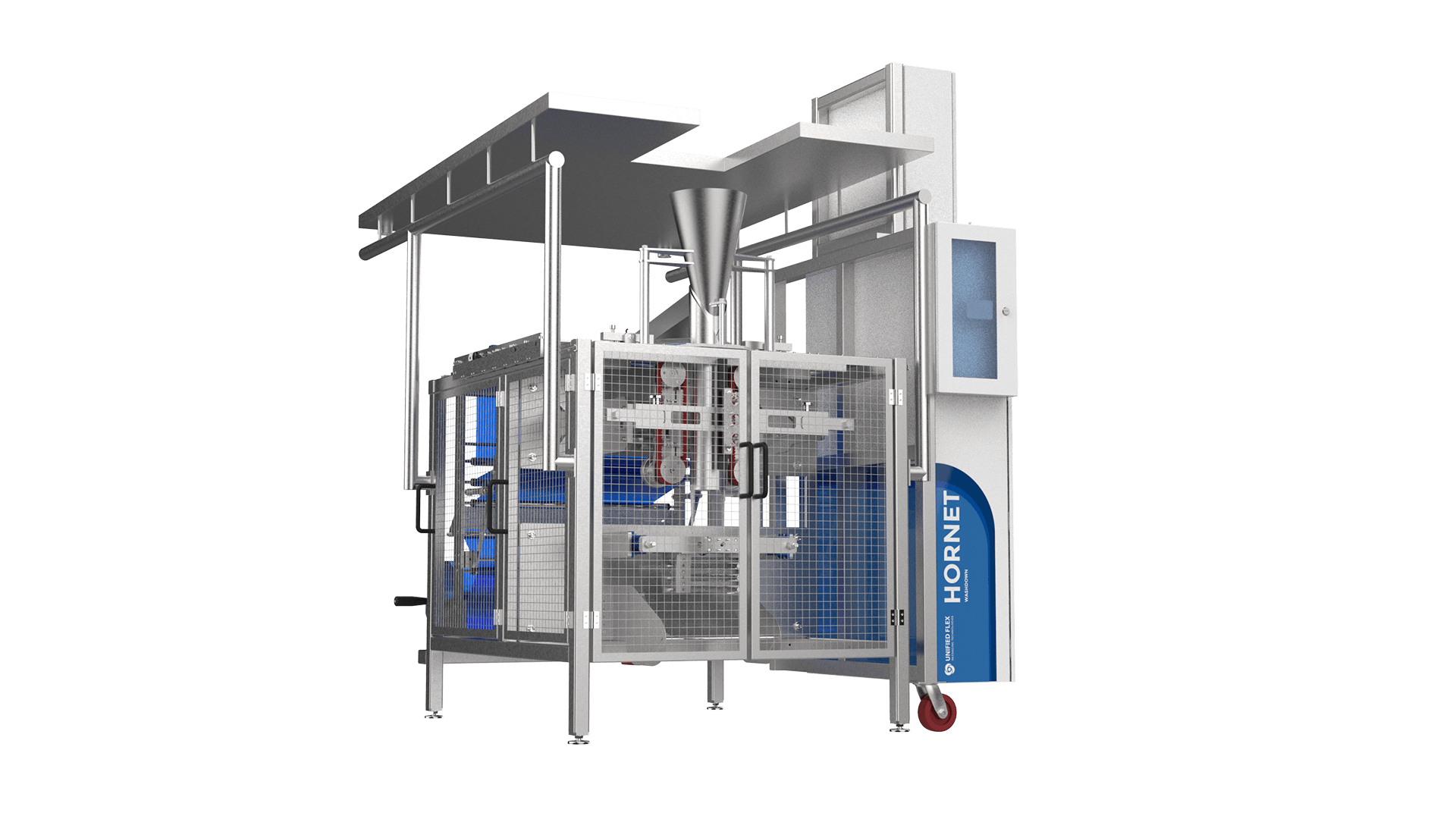

VFFS Intermittent Motion Machine - Premium

VFFS Vertobagger Hornet XL

minute max.

bag width

bag length

VFFS Vertobagger Hornet

minute max.

bag width

bag length

VFFS Vertobagger Hornet Washdown

minute max.

bag width

bag length

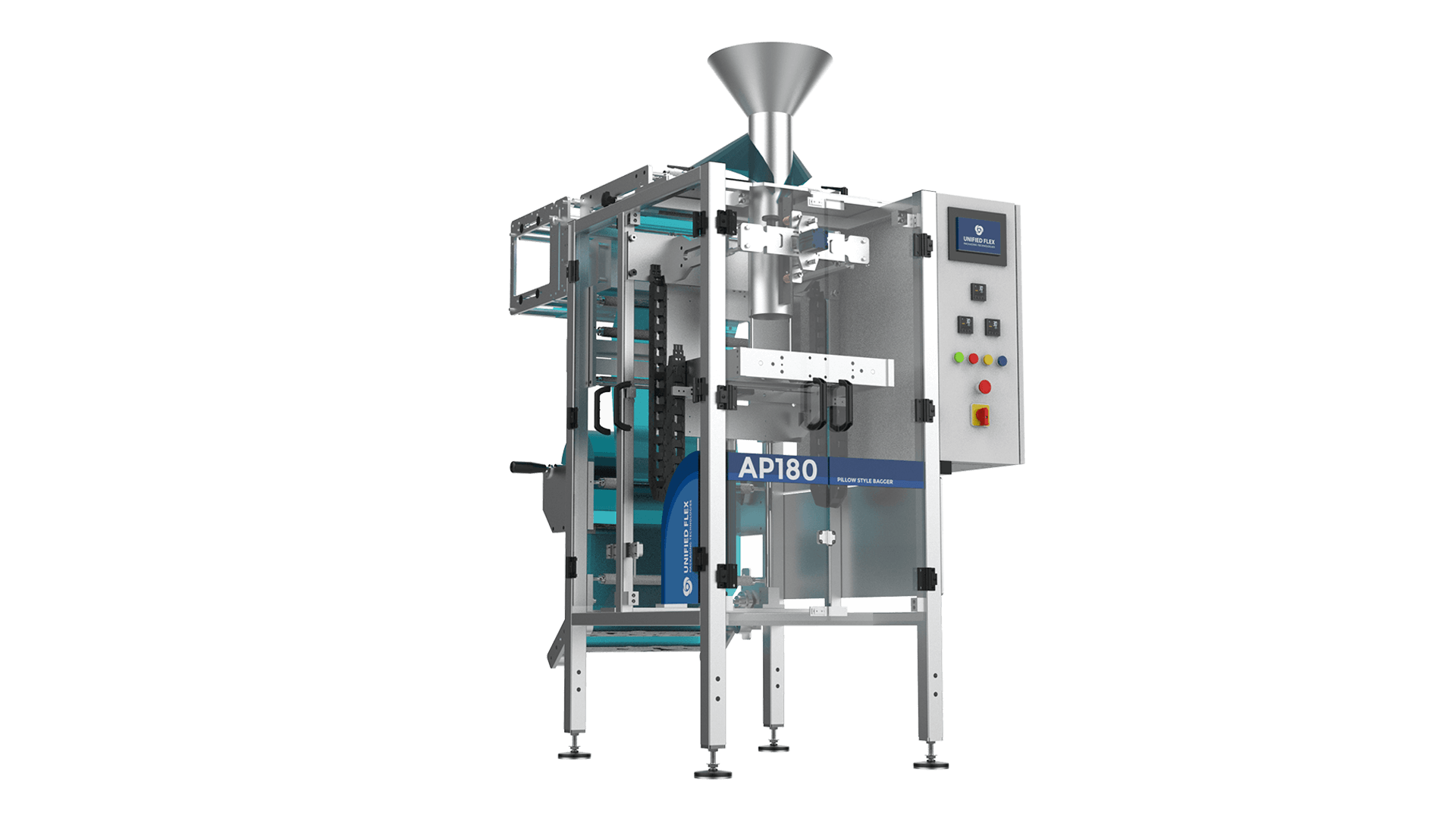

VFFS Intermittent Motion Machine - Economy

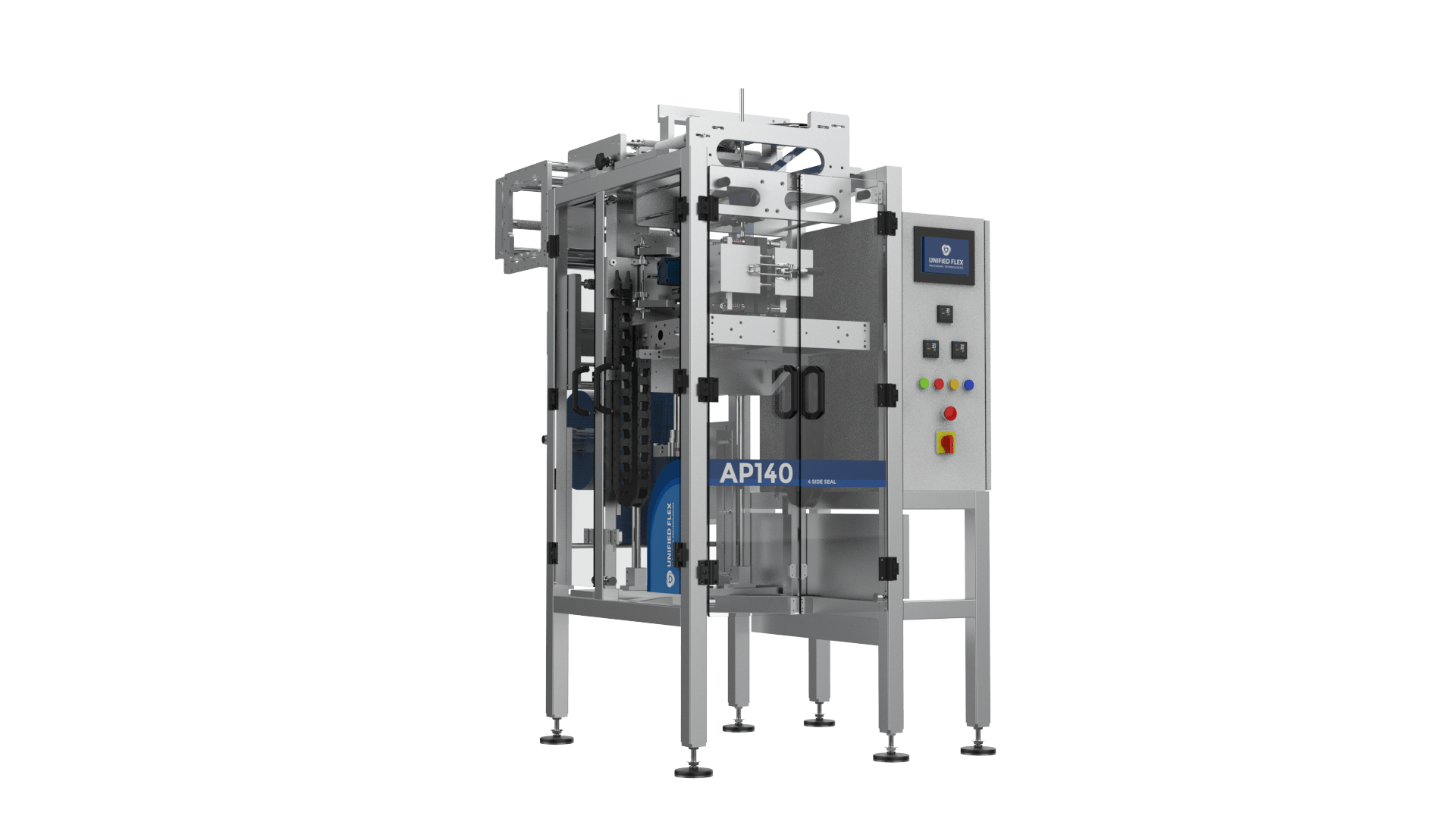

Auto Pouch Bagger AP-140

minute max.

bag width

bag length

VFFS Vertobagger Maverick

minute max.

bag width

bag length

Auto Pouch Bagger AP-180

minute max.

sachet width

sachet length

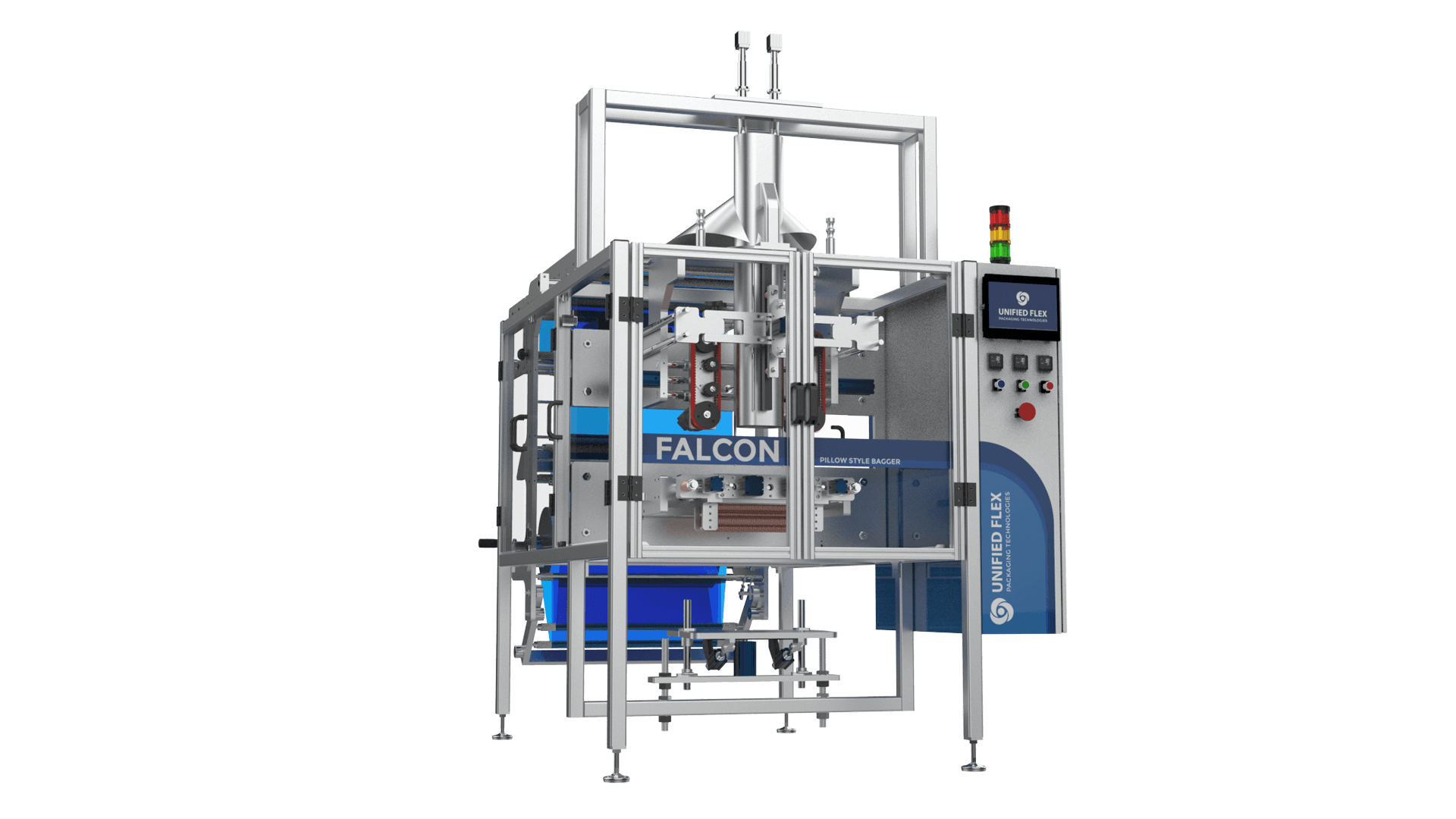

VFFS Vertobagger Falcon

minute max.

bag width

bag length

Stick Pack Machines

Auto Pouch Bagger AP-140 Stick Pack

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 300mm

minute max.

stick pack width

stick pack length

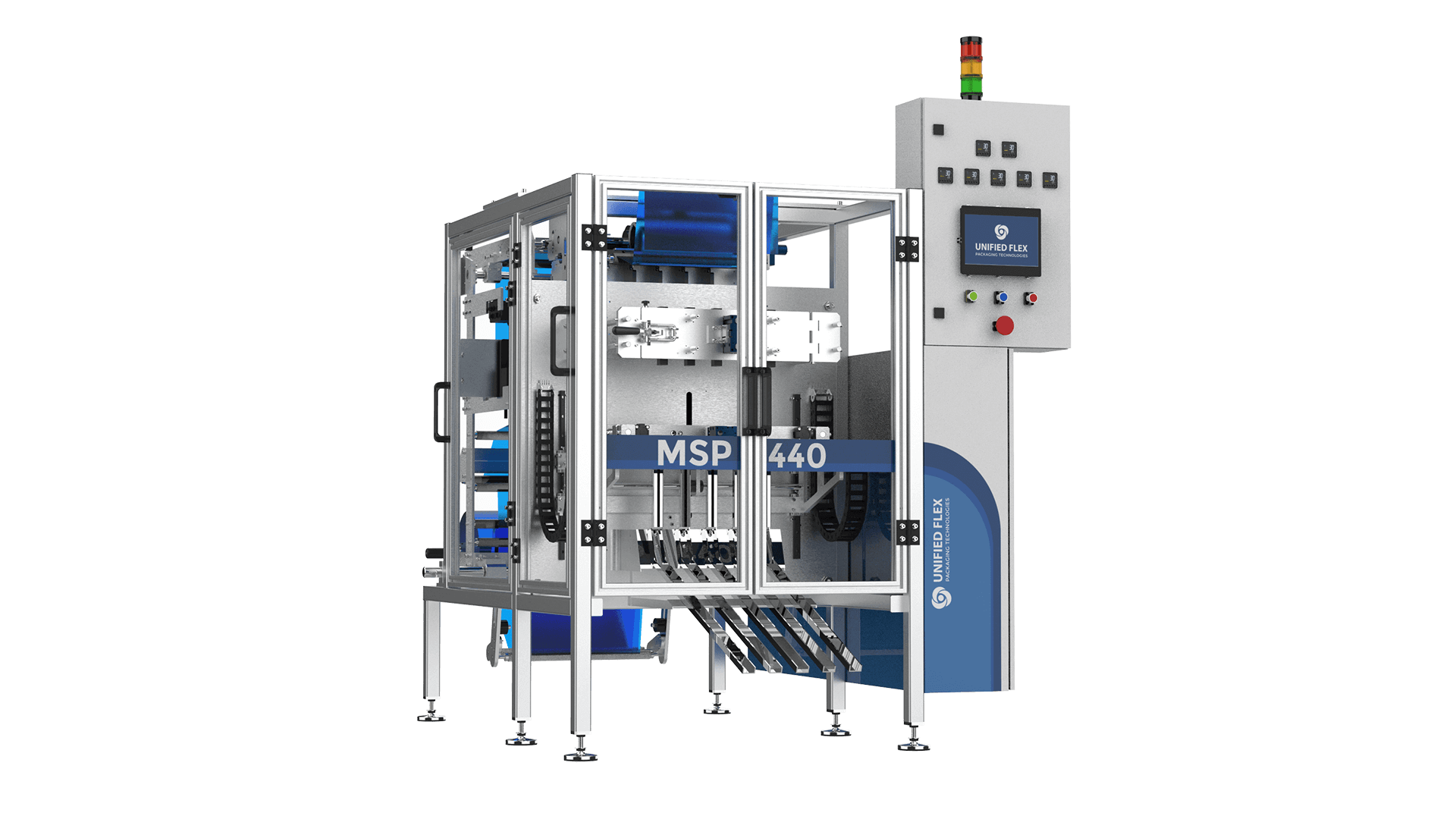

Multilane Stick Pack – MSP 440mm

minute max.

stick pack width

stick pack length

Multilane Stick Pack – MSP 800mm

minute max.

stick pack width

stick pack length

Sachet Machines

Auto Pouch Bagger AP-140 Sachet

minute max.

sachet width

sachet length

Auto Pouch Bagger AP-180 Sachet

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 406mm

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 508mm

minute max.

sachet width

sachet length

Multilane Sachet Bagger – MSB 813mm

minute max.

sachet width

sachet length

VFFS Continuous Motion Machines

VFFS Vertobagger 2.0

minute max.

bag width

bag length

VFFS Vertobagger 2.0 Ultrasonic

minute max.

bag width

bag length