Ensuring the freshness, consistency, and integrity of powdered food products is essential in packaging. Modern automated packaging machines incorporate several features to maintain product quality and shelf life, including:

1. Nitrogen Flushing for Extended Shelf Life

- Prevents oxidation and moisture absorption, which can cause clumping and spoilage.

- Removes oxygen from the package, preserving flavor, color, and texture.

- Ideal for protein powders, drink mixes, and coffee-based products.

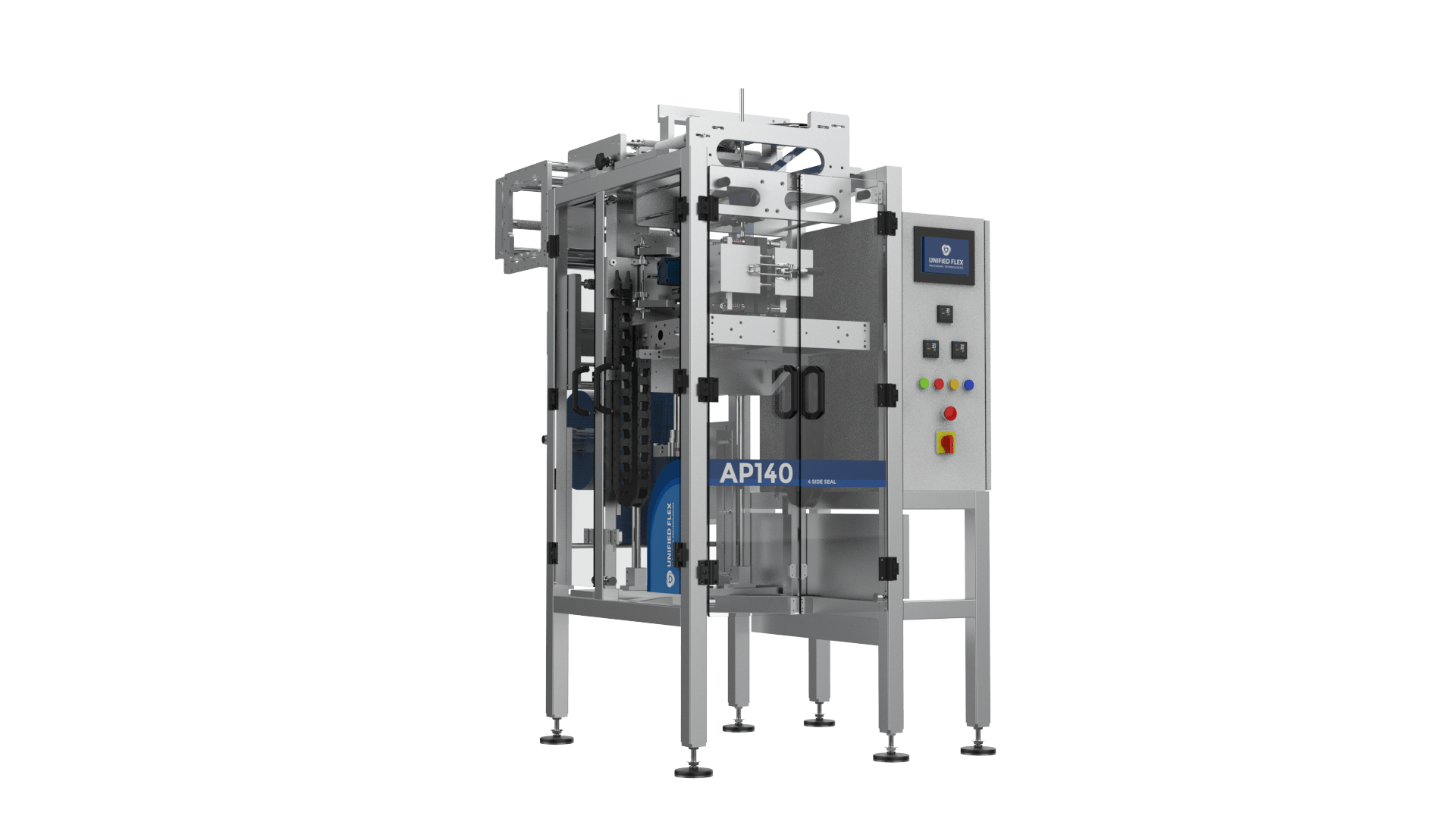

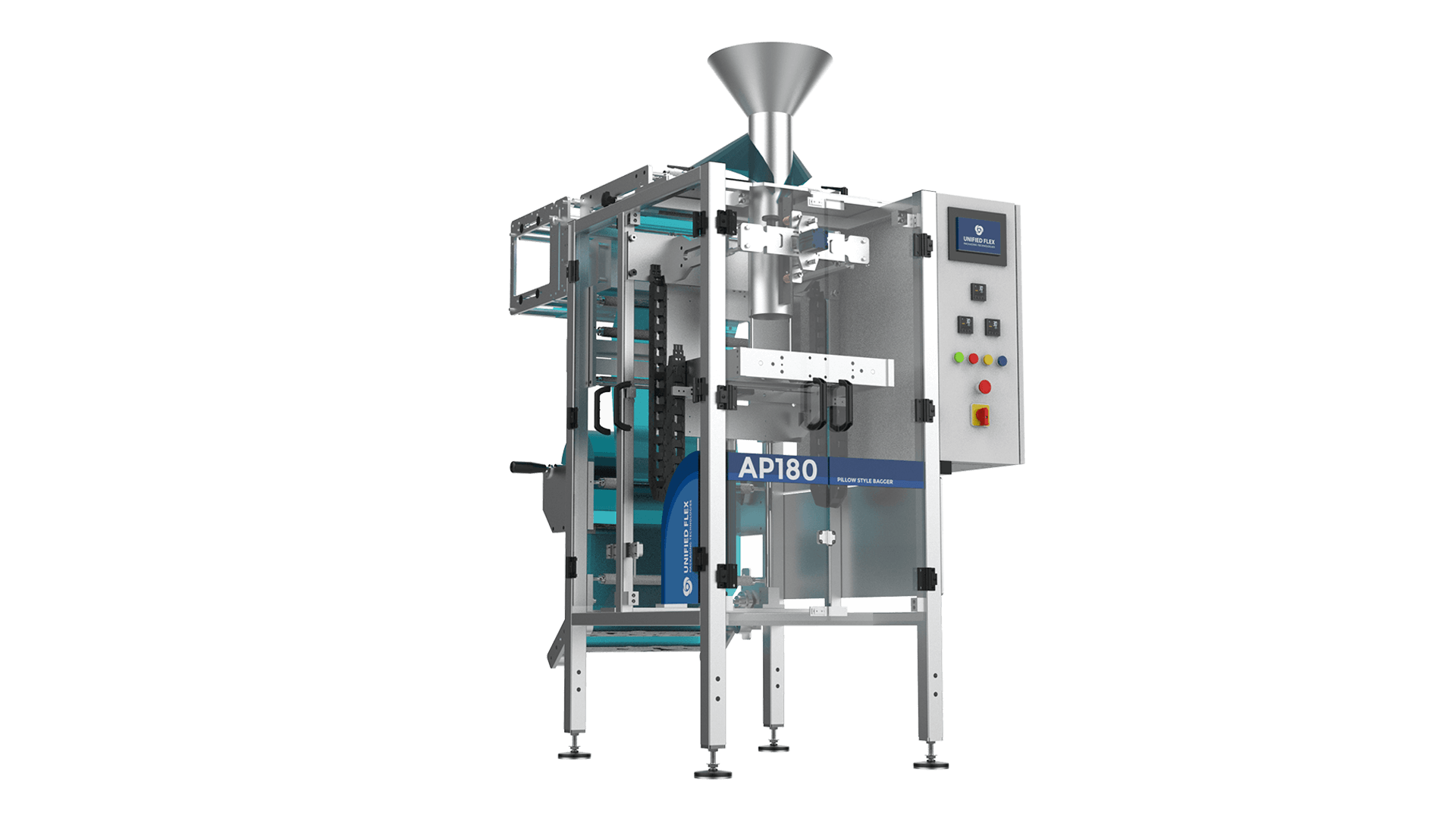

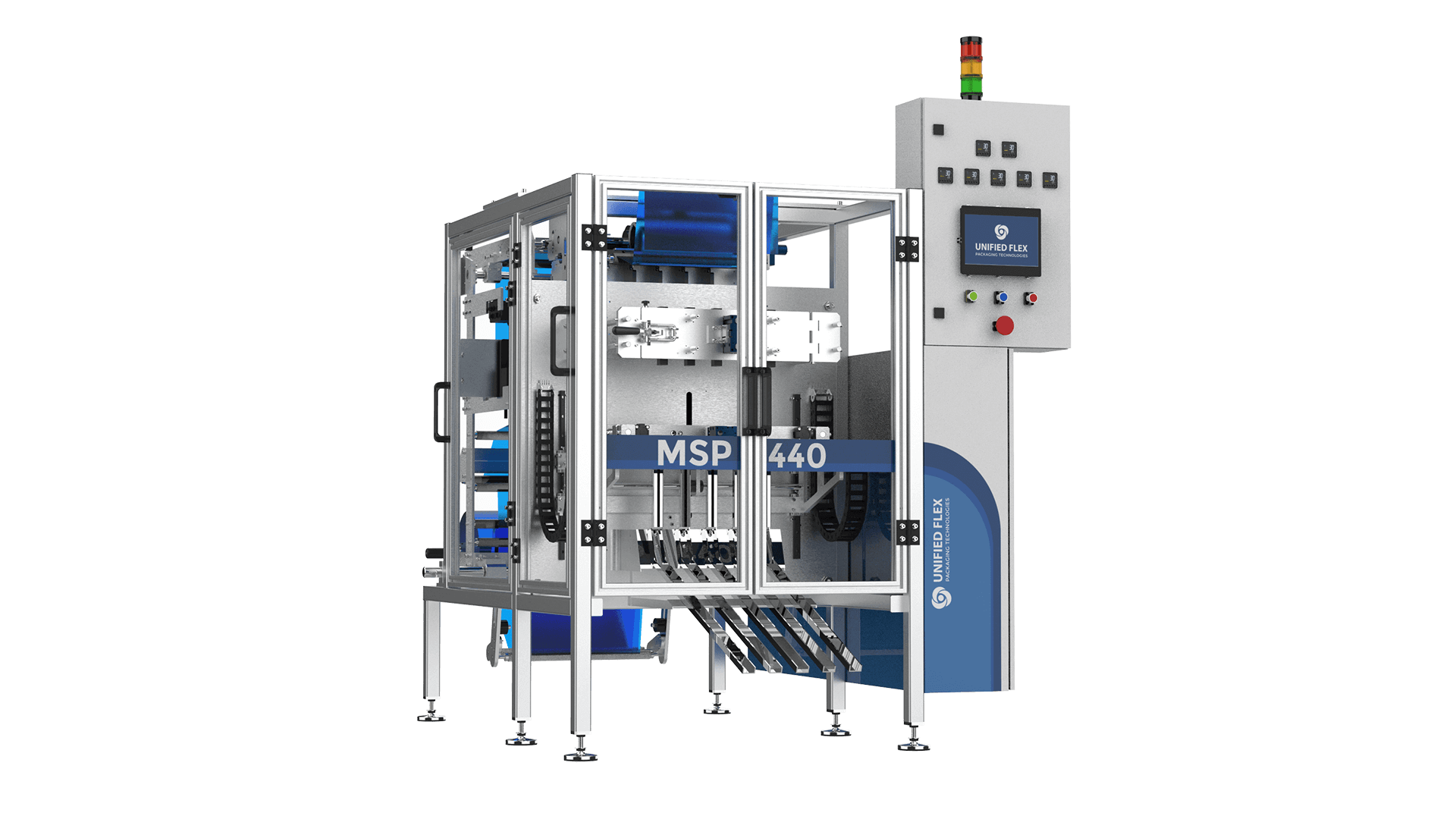

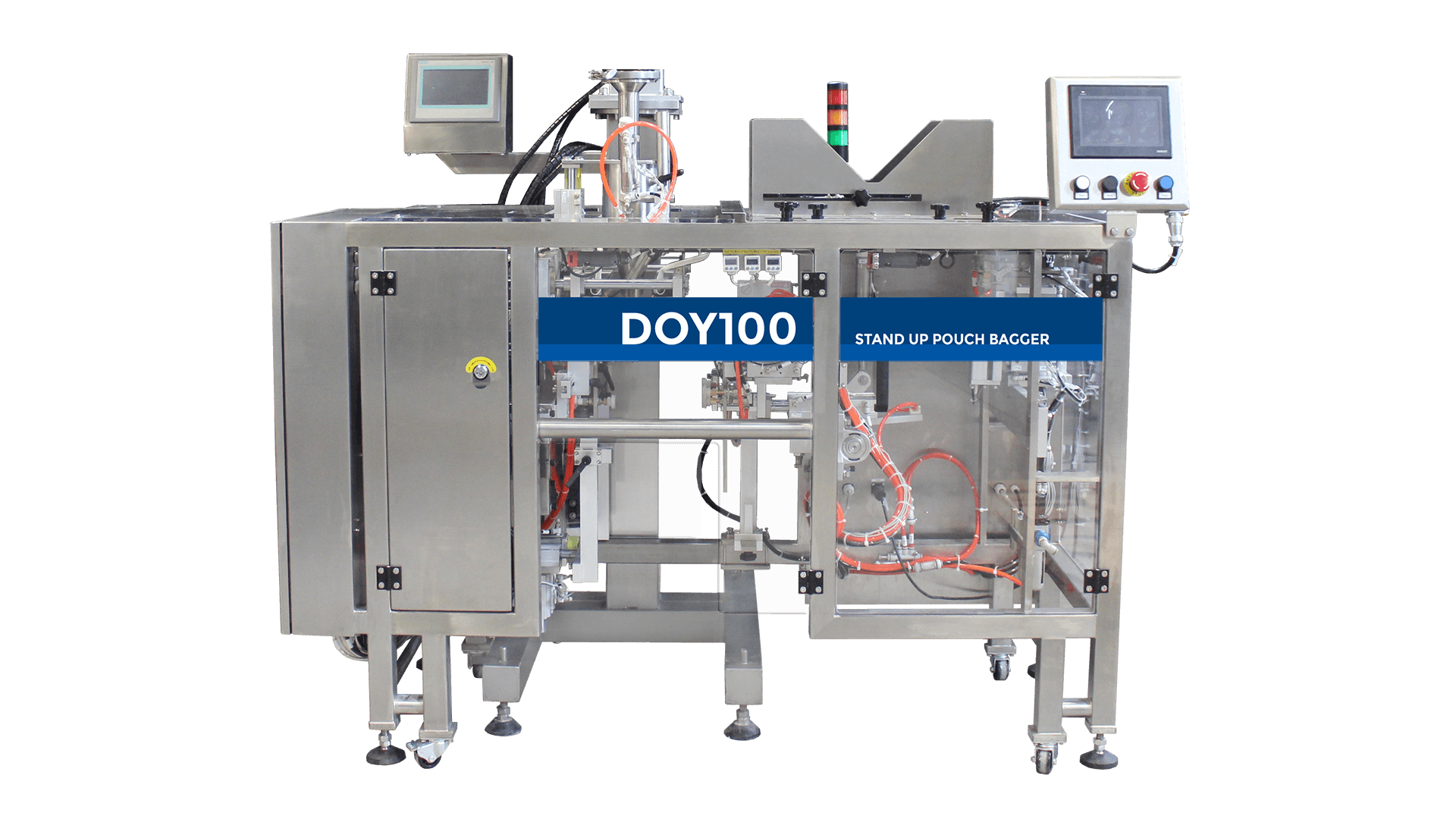

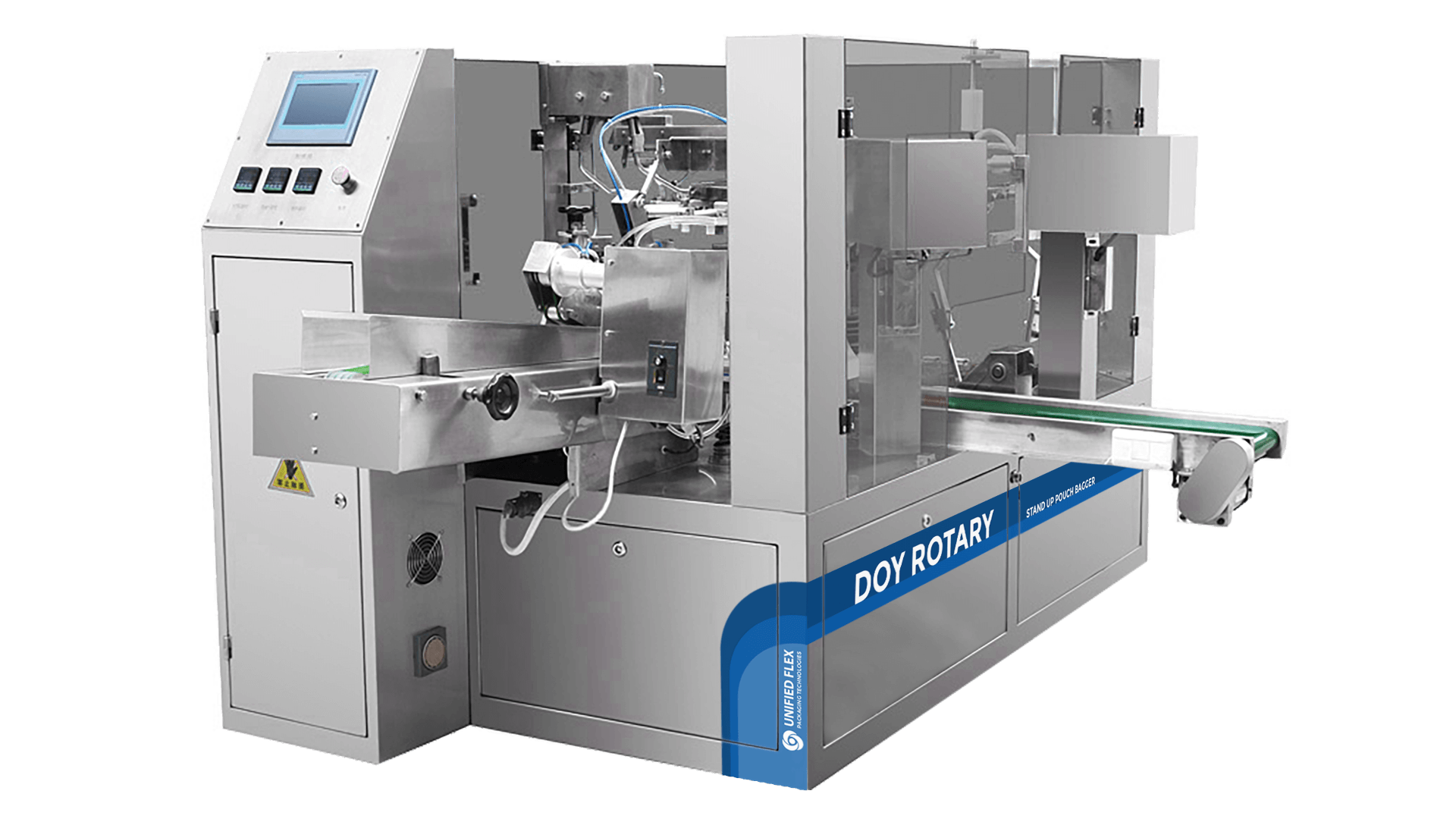

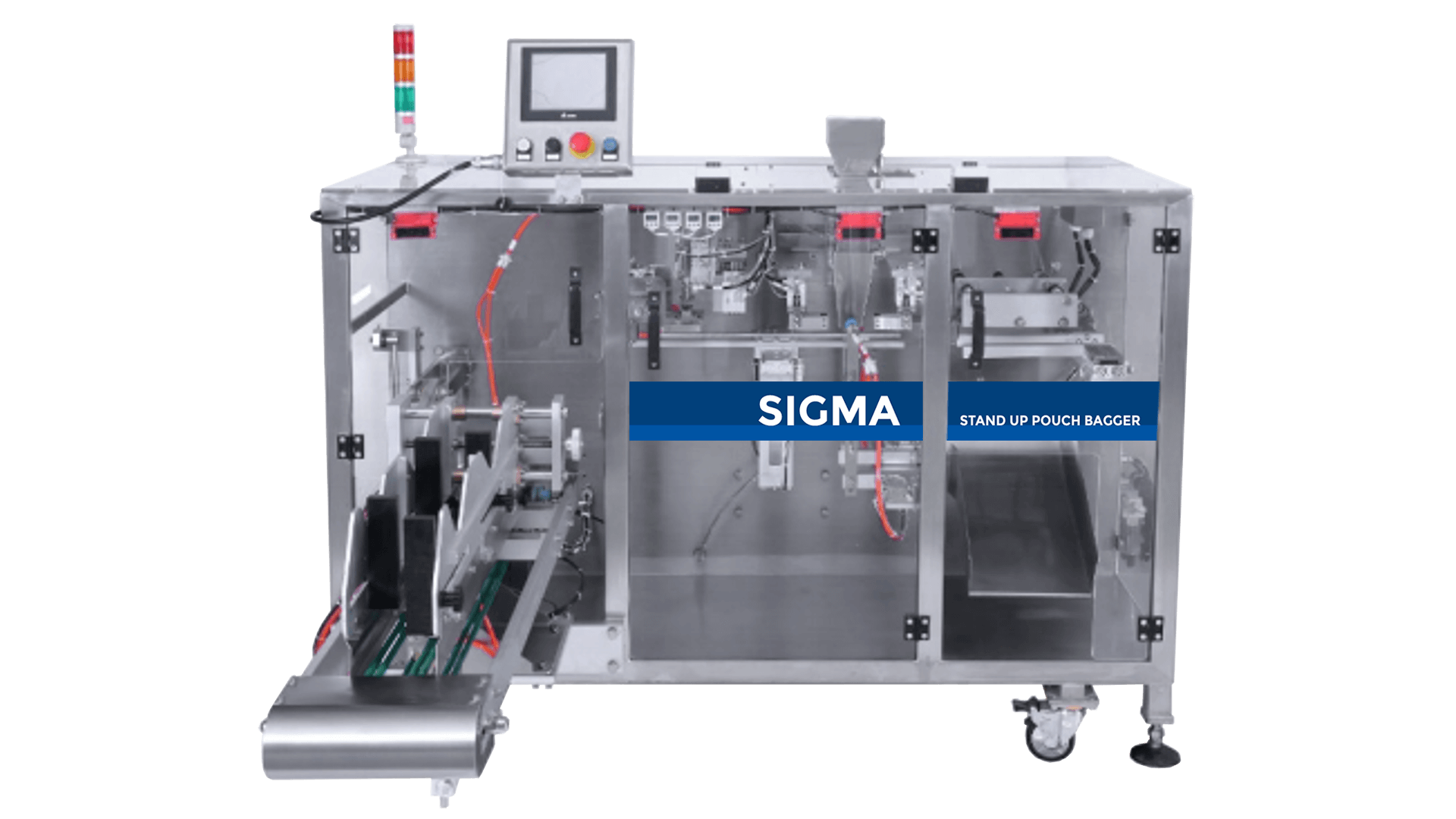

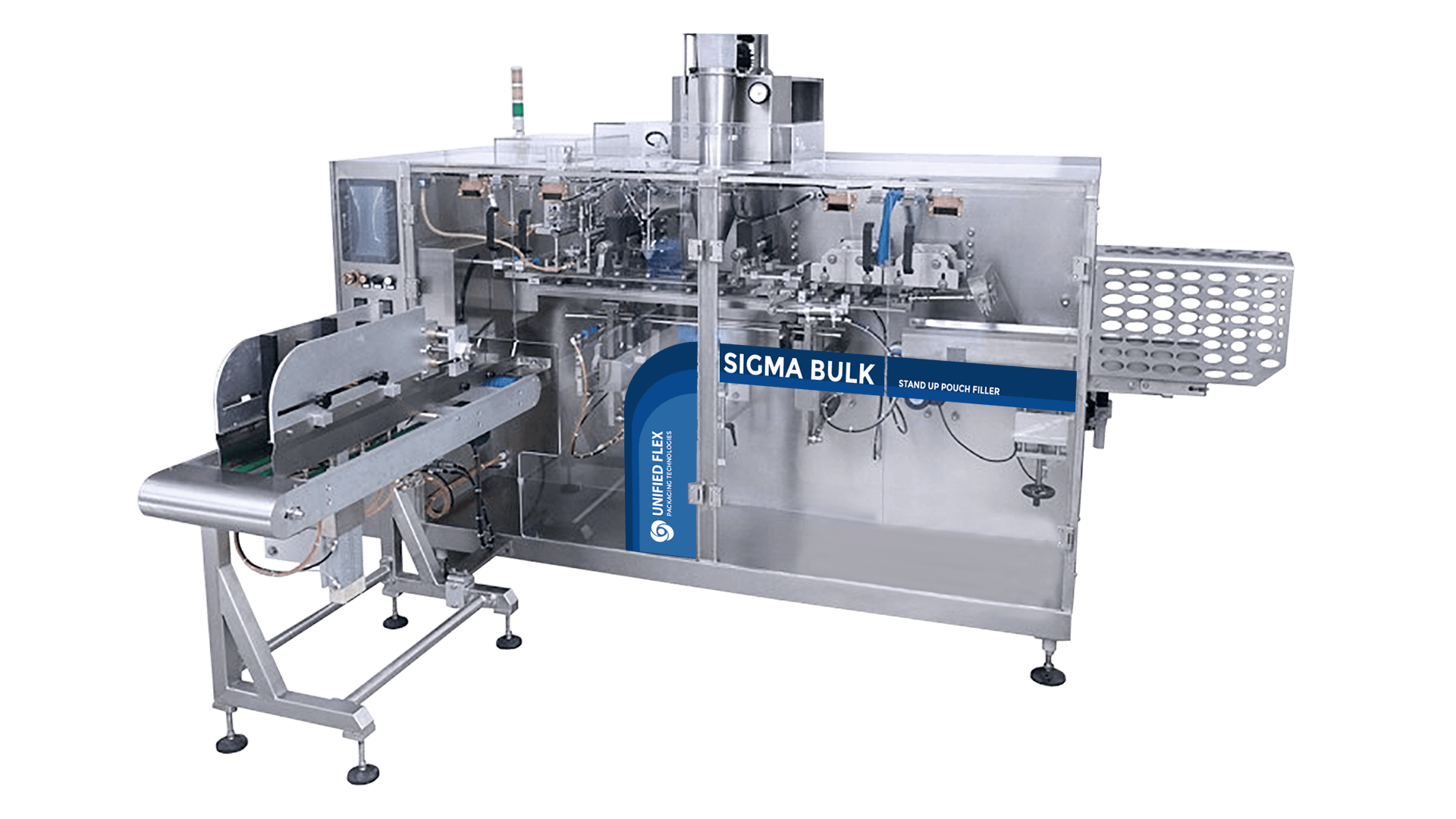

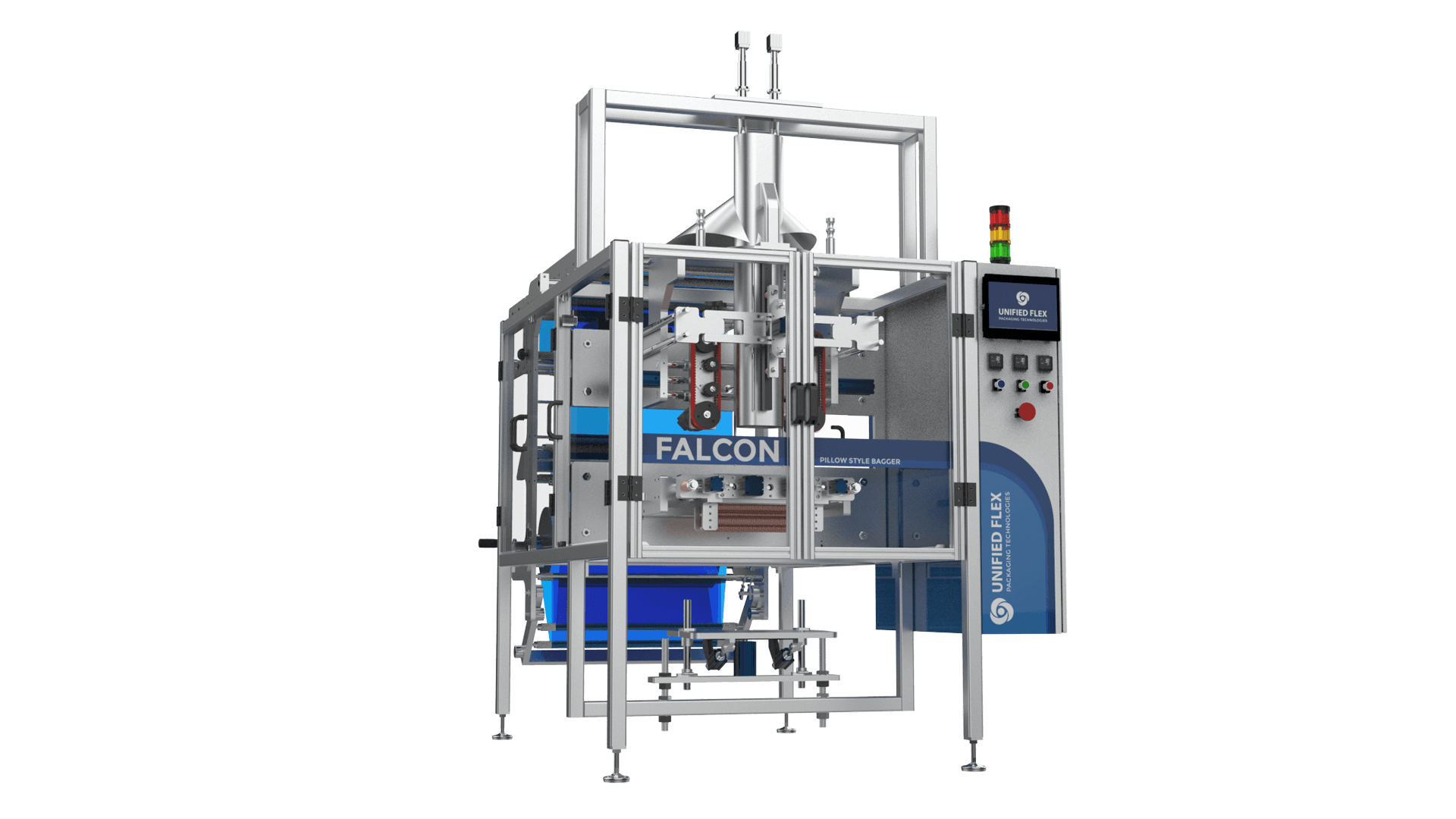

Unified Flex Solution: Our VFFS, Stick Pack, Sachet, and Stand-Up Pouch Bagging Machines come with an optional nitrogen flush system to help maintain product freshness.

2. Hygienic Design

- Stainless steel contact surfaces meet food safety regulations and are easy to clean.

- Sealed product pathways prevent contamination and maintain hygiene.

Unified Flex Solution: Our machines feature 304 stainless steel construction, sanitary contact parts, and easy-to-clean surfaces, ensuring compliance with food industry hygiene standards.

3. Accurate & Consistent Filling Systems

- Auger Fillers: Best for fine, dusty powders (e.g., protein powder, cocoa, flour).

- Volumetric Cup Fillers: Suitable for free-flowing powders (e.g., drink mixes, sugar).

- Multi-Head Weighers: Ideal for precise weight-based dispensing.

Unified Flex Solution: Our packaging machines integrate precision dosing systems, including auger fillers, volumetric fillers, and combination weighers, to ensure accurate, repeatable fill weights and reduce product giveaway.

4. Strong & Reliable Seal Integrity

- Vacuum sensors ensure proper bag opening before filling.

- Advanced sealing jaws create leak-proof, airtight seals for maximum freshness.

- Temperature-controlled sealing prevents damage to delicate powder products.

Unified Flex Solution: Our machines feature PLC-controlled sealing jaws, vacuum sensors, and precision temperature regulation to ensure perfect seals every time .

5. Zipper & Spout Applicators for Resealability

- Zipper seals & resealable spouts keep powders fresh after opening.

- Enhances consumer convenience and product shelf life.

- Ideal for stand-up pouches with premium drink mixes or nutritional powders.

Unified Flex Solution: Our stand up pouch bagging machines support resealable zippers and spouts for premium powder packaging.

6. Product Settling & Gentle Handling

- Bag shaking & hopper shaking minimize trapped air for consistent fill levels.

- Controlled product flow prevents powder dust buildup inside the machine.

Unified Flex Solution: Our stand up pouch bagging machines offer bag shaking, product settling, and controlled filling mechanisms to improve package consistency.

Unified Flex designs custom-engineered powder packaging solutions that enhance product quality, accuracy, and efficiency. Whether you need stick packs, sachets, VFFS bags, or stand-up pouch packaging machines, we provide innovative and reliable solutions tailored to your needs.

Contact us today to optimize your powder packaging!