Why Stick Pack Machines Are Popular in the Food and Pharma Industry

If you’ve spent years in the food or pharmaceutical business, you already know the pressure never really stops. Tight deadlines, regulatory compliance, rising material costs, and let’s not forget the constant demand for packaging that is cleaner, faster, and more efficient. Consumers want convenience; your operations need precision. Balancing both can feel like walking a tightrope.

That’s exactly where stick pack machines are changing the game. They’re not just about sleek single-serve packaging; they’re about streamlining production, cutting waste, and ensuring consistency from the first pack to the millionth. For engineers, plant managers, and business leaders who care about long-term reliability and ROI, stick pack automation isn’t an upgrade; it’s the standard for staying competitive.

At Unified Flex, we design machines that think like you do: focused on uptime, accuracy, and total line efficiency. In this blog, we’ll break down how stick pack machines are transforming food and pharma manufacturing, why leading brands trust them, and how our engineered solutions help you stay ahead in an industry where precision and performance define success.

The Role of Stick Pack Machines in Food and Pharma Packaging

Stick pack packaging machines are now a cornerstone of modern food and pharmaceutical production lines. From instant drinks to single-dose medications, global brands rely on them for precise, hygienic, and cost-effective single-serve packaging that delivers both efficiency and consumer convenience.

Here’s how major players across industries are using them:

Instant Coffee & Drink Mixes:

Brands like Nescafé and Nestlé Milo rely on high-speed stick pack machines to produce perfectly portioned servings at scale. Automated dosing and sealing systems ensure every pack maintains the same flavor, aroma, and quality.

Electrolyte & Nutrition Powders:

Sports and wellness brands such as Gatorade and Pedialyte use stick pack machines to achieve consistent fill accuracy and rapid output. This ensures reliable, ready-to-mix hydration solutions that align with the active consumer lifestyle.

Sugar, Creamer & Seasoning Sticks:

Restaurants, cafes, and food service providers increasingly depend on stick pack machinery to package individual portions of sugar, salt, pepper, and creamer, delivering improved hygiene, portion control, and reduced contamination risk.

Vitamin & Supplement Powders:

Health and wellness manufacturers use stick pack machines to package powdered vitamins, collagen, and probiotics into easy-to-consume single servings. Precision filling and sealing help maintain freshness and ensure accurate dosages in every pack.

Cold & Flu and Oral Rehydration Powders:

Pharmaceutical companies like GSK (Panadol Cold & Flu) and Abbott (ORS) rely on advanced stick pack machines for precise dosing and hermetic sealing, critical for maintaining safety, compliance, and product integrity.

Why Businesses Trust Unified Flex Stick Pack Machines

At Unified Flex, every feature is designed with your operational needs in mind. Here’s how our machines deliver value across your production line:

Customization

Every production line is unique. That’s why our machines are modular and fully configurable:

- Lane configurations from 1 to 16 lanes to match your volume needs.

- Output speeds range from 40 to 800 stick packs per minute.

- Compatibility with powders, granules, liquids, and gels.

- Adjustable web width and sealing options to suit different product types.

Benefit to you: You get a stick pack machine designed specifically for your products, production targets, and space requirements.

Experience & Expertise

With nearly two decades of experience in flexible packaging automation, Unified Flex has earned a reputation for technical mastery and dependability. Based in Woodstock, Ontario, we have been designing and manufacturing superior-quality flexible packaging systems since 2007. Our engineering team brings a combined 50 years of hands-on experience across a wide variety of industries, ensuring that every automatic packaging machine meets the highest standards of performance.

Partnering with Unified Flex means working with a team that has a proven track record, minimizing risk while maximizing line efficiency. Our clients consistently report measurable improvements in throughput, OEE, and product consistency.

Feature-to-Benefit Connection

Every feature of our stick pack machines translates into a business advantage:

- Servo-driven auger fillers and volumetric dosing systems ensure accurate product measurement for every pack, reducing waste and ensuring compliance in pharmaceutical applications.

- Multi-lane configurations allow rapid scaling without compromising quality.

- Heat sealing and ultrasonic options offer secure seals, ensuring shelf stability and product freshness.

- Tear notches and perforations enhance consumer convenience while maintaining integrity.

Process-Driven Approach

Our machines aren’t just built to run; they’re engineered to integrate smoothly into your existing operations. From design and rigorous testing to installation and operator training, our structured, process-driven approach ensures minimal downtime, predictable output, and reliable operation, critical for high-value equipment where production continuity is paramount.

Service & Support Assurance

At Unified Flex, service doesn’t stop at installation. We provide fast access to parts, routine maintenance, and expert troubleshooting whenever you need it. Our commitment ensures that your machine operates at peak efficiency throughout its lifecycle.

Benefit to you: Reduced risk of production delays and peace of mind knowing support is only a call away.

Addressing the Packaging Challenges in Food & Pharmaceutical Production

S.No | Industry Challenges | How Our Stick Pack Machines Solve Them |

1. | Inconsistent product dosing and portion control | Advanced servo-driven filling ensures precise and repeatable dosing every time |

2. | Excessive packaging waste and material usage | Optimized film usage design reduces material consumption by up to 40% |

3. | Slow production speeds and low efficiency | Multi-lane high-speed operation delivers fast and consistent output |

4. | Risk of contamination during manual handling | Fully automated filling and sealing minimize human contact for hygienic packaging |

5. | Short product shelf life due to poor sealing | Airtight, high-barrier sealing maintains freshness and extends shelf life |

6. | Limited portability and consumer convenience | Compact, single-serve stick packs are easy to carry, store, and use |

7. | High operational downtime and maintenance issues | Quick-change, low-maintenance designs maximize uptime and productivity |

8. | Difficulty maintaining packaging accuracy at scale | Smart controls and sensors ensure accuracy even during large-scale runs |

9. | Rising demand for sustainable packaging | Compatible with recyclable and biodegradable films to support eco goals |

10. | Complex changeovers between product types | Modular setup enables easy, tool-free changeovers for different products |

Need a High-Speed Stick Pack Solution for Your Food or Pharma Operations?

Unified Flex Stick Pack Machines are built to deliver unmatched speed, accuracy, and hygiene in every pack. Whether you’re packaging powders, liquids, or granules, our machines ensure reliable, consistent, and efficient performance.

With 1–16 lanes and speeds up to 800 stick packs per minute, they offer flexible options for different product types, sizes, and seal styles, perfect for today’s on-the-go consumers.

Machine Highlights

- 40–800 Stick Packs/Minute

- 1–16 Lanes

- Max Web Width: 31.49″ (800mm)

- Max Cycles: 50 per Minute

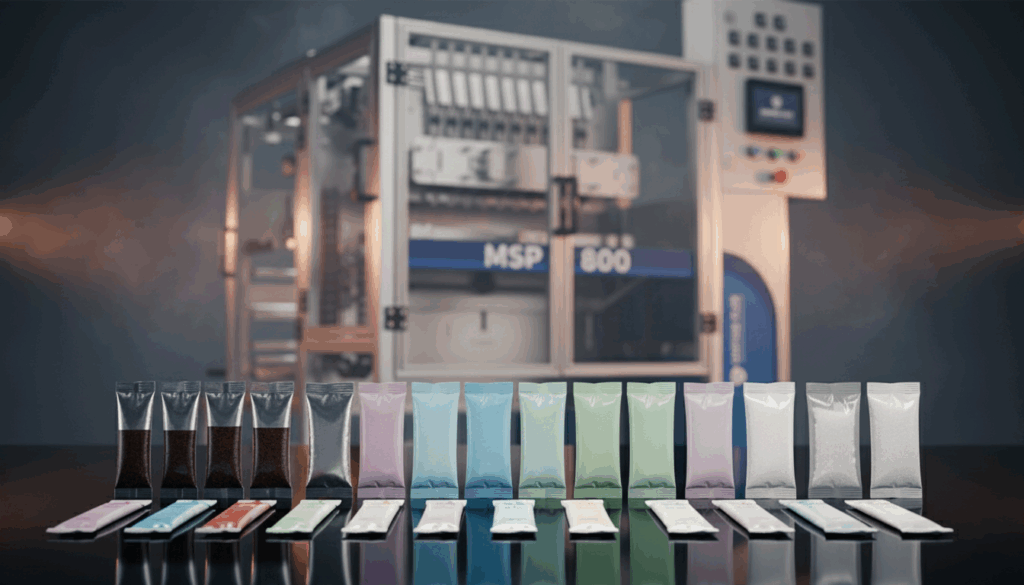

Our Top Models

- AP-140 Stick Pack Machine – Simple, precise, and easy to maintain.

- MSP 300mm – Ideal for low to medium volumes (up to 6 lanes).

- MSP 440mm – High-speed output up to 400 packs/min.

- MSP 800mm – Heavy-duty model for large-scale production (up to 800 packs/min).

Ready to upgrade your production line? Get a free consultation with our packaging experts and discover which Stick Pack Machine best fits your needs.

Putting It All Together

In the food and pharmaceutical industries, every second counts and every dose matters. Stick pack packaging machines have become the go-to solution for brands that need speed, accuracy, and hygiene, all in one system. Our Stick Pack Machines help you package smarter, faster, and cleaner, meeting the industry’s demand for convenience and precision.

If you’re scaling production or optimizing existing lines, our machines are built to perform and engineered to last. Get in touch with us today!