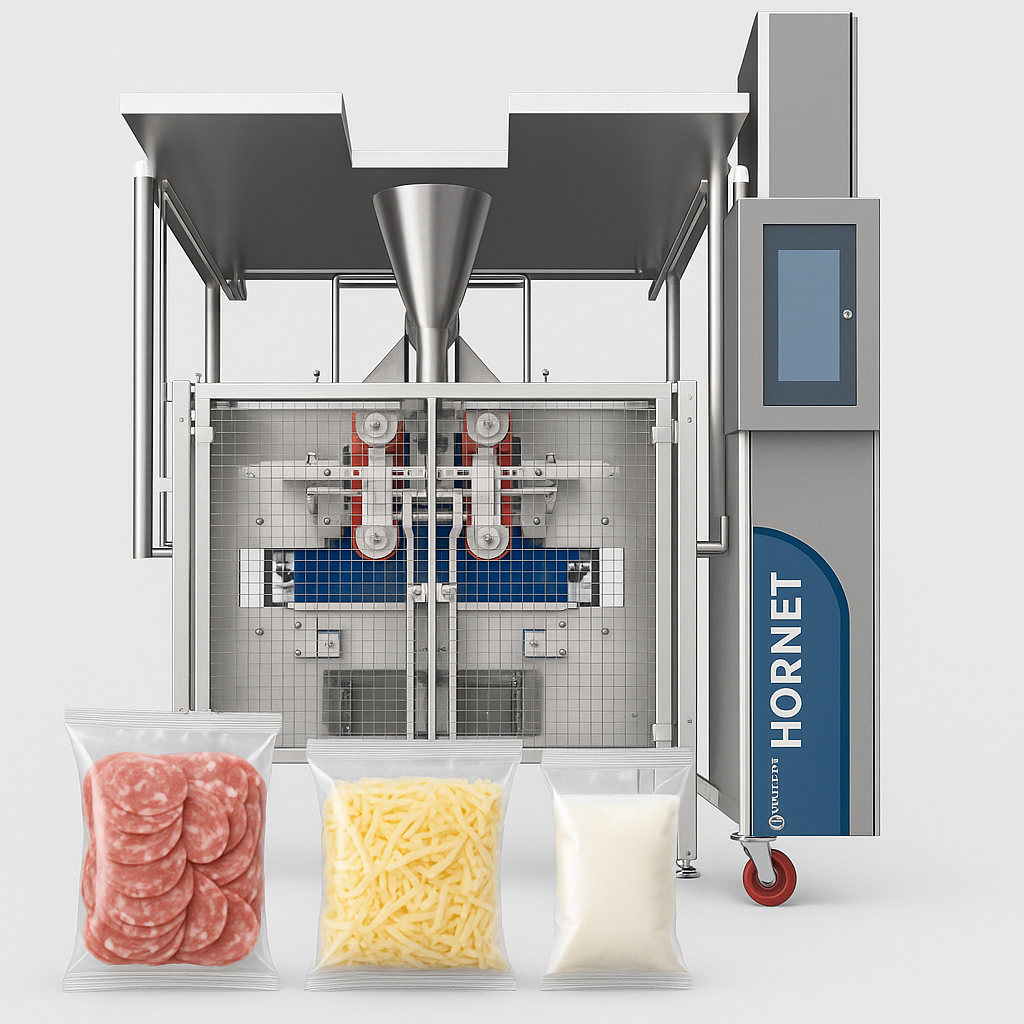

Washdowns don’t have to waste hours of production time. In dairy, meat, and cheese packaging, the right machine can mean stronger seals, faster changeovers, and less downtime. Learn how the Hornet Washdown, a rugged, customizable dairy packaging machine is helping producers reclaim uptime, protect shelf life, and stay competitive in the cold chain.

Read the blog to see how smarter packaging machines solve the real challenges dairy, meat, and cheese producers face.