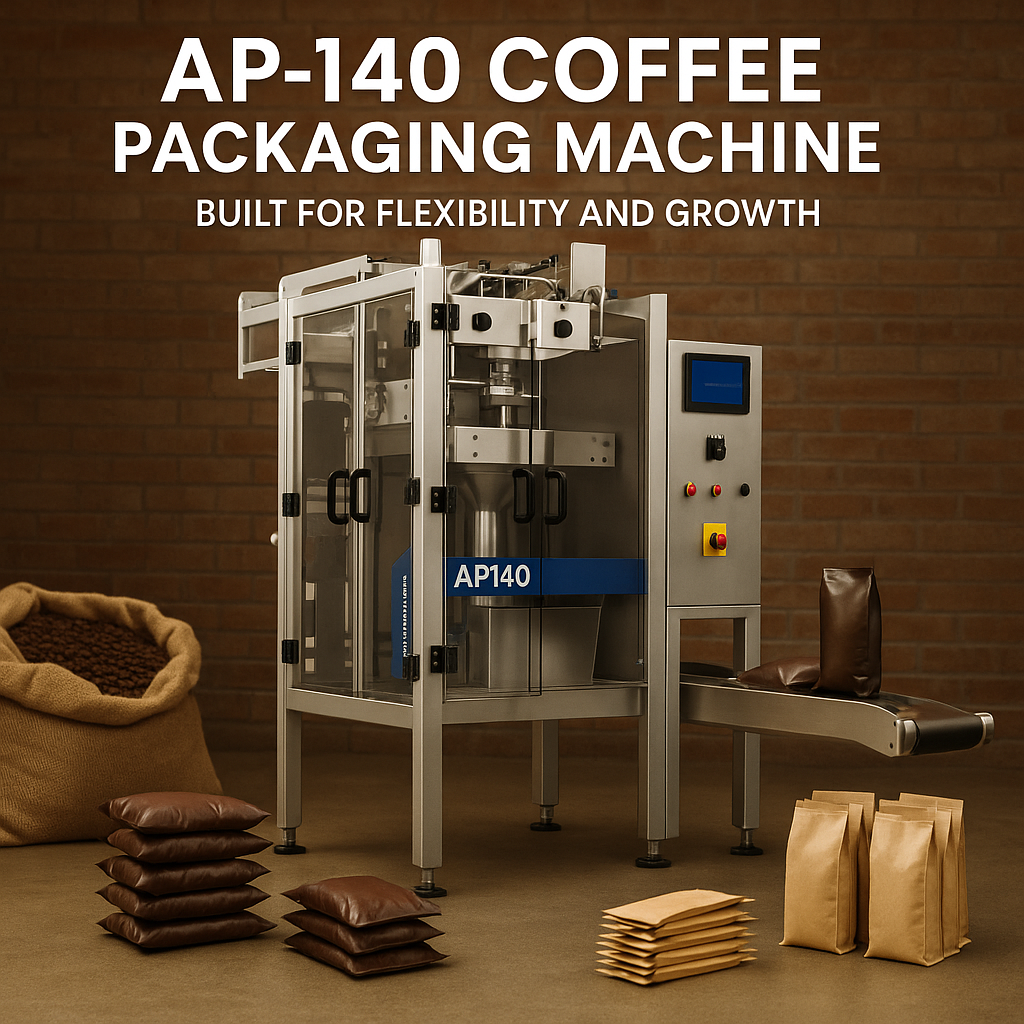

Looking for a fast, reliable, and flexible packaging solution? Unified Flex’s Vertobagger Series is changing the game in vertical form fill and seal (VFFS) packaging. It’s built for speed, works with all kinds of products, and is super easy to use. Read the full blog to find out how the Vertobagger Series can boost your packaging line.