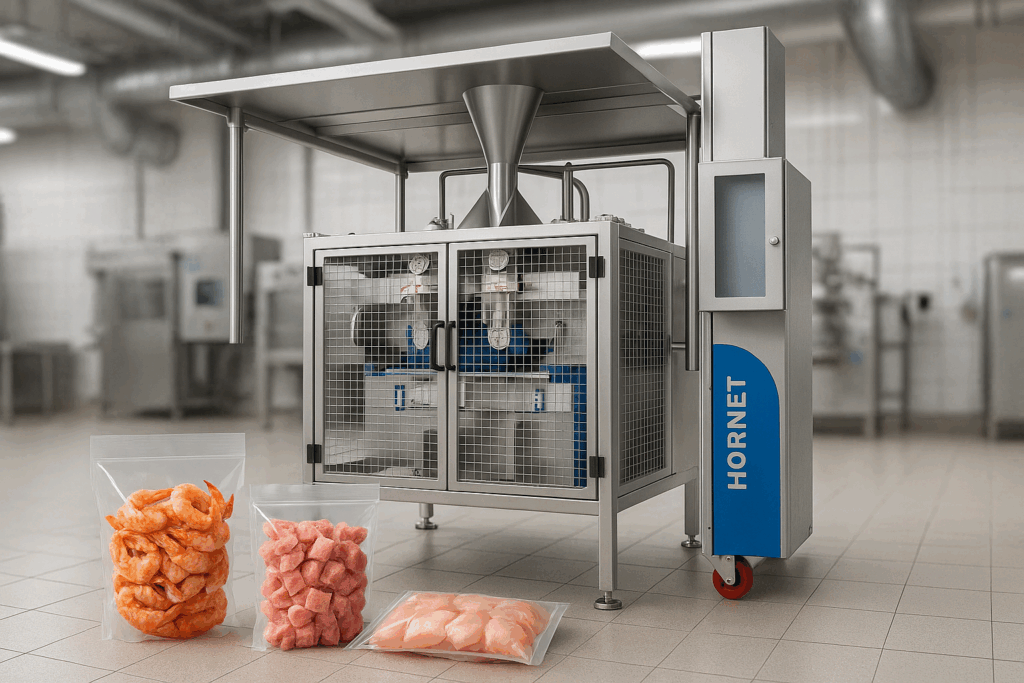

Seafood, poultry, and meat packaging face strict hygiene, cold chain, and efficiency demands. Discover the key challenges processors face and how a washdown-ready meat packaging machine can solve them with faster sanitation, consistent seals, and reliable performance.