The Nutraceutical Packaging Machine That’s Built for Growth

Introduction: Why Packaging is the New Battleground

The nutraceutical industry is booming. From personalized vitamin powders and herbal extract sachets to protein drink mixes and functional gummies, demand is higher than ever. Consumers want convenient, personalized health solutions they can trust, delivered right to their doorsteps.

But while brands race to meet that demand with new formulations and more SKUs, one critical challenge has quietly moved to the center of the conversation: packaging.

It’s not enough to have an innovative formula or appealing branding. To stay competitive and grow sustainably, nutraceutical brands need a nutraceutical packaging machine that does more. One that protects product integrity, supports regulatory compliance, adapts to SKU complexity, and delivers consistent, reliable output.

Because when packaging fails, the entire promise of the brand fails with it.

Real-World Challenges in Nutraceutical Packaging

SKU Complexity and Changeover Headaches

Look at any supplement aisle or online wellness store. Variety is the standard. You’ll see immunity powders in stick packs, sleep-support gummies in single-dose pouches, and protein blends in resealable bags.

This variety is what customers expect, but it adds real complexity to the production floor. Every new SKU means another format to manage. Outdated or single-format equipment can turn this into a daily bottleneck. Time lost to changeovers, tooling swaps, and setup delays adds up fast.

Brands need a nutraceutical packaging machine that can handle this complexity without sacrificing throughput or quality.

Powders, Liquids, and Gummies: One Line, Many Challenges

Nutraceutical producers don’t work with a single product type. Powders flow differently than liquids. Sticky herbal extracts have unique filling needs. Gummies can jam or bounce in ways loose powders don’t.

A one-size-fits-all approach rarely delivers. Equipment that can’t adapt creates spills, waste, and extended cleaning downtime. Over time, that’s not just an operational inconvenience; it’s a cost center that limits your ability to scale.

A nutraceutical packaging machine must be versatile enough to handle this product diversity reliably, batch after batch.

Precision Matters: Dosing and Compliance

Packaging nutraceuticals is about more than filling a pouch. It’s about filling it correctly.

Underfilled products can trigger consumer complaints, returns, and damage to your brand’s credibility. Overfilled pouches waste expensive active ingredients and eat into margins on every unit.

Meanwhile, regulators expect clear Supplement Facts panels, ingredient lists, and precise batch or lot codes. Any failure in traceability or labeling can mean fines, recalls, and reputational damage.

A nutraceutical packaging machine needs to deliver precise, repeatable fills and support integrated traceability.

Protecting Sensitive Ingredients

Many nutraceutical products include active ingredients that degrade quickly if exposed to oxygen or moisture. Even slight variations in seal quality or barrier performance can reduce potency before the customer ever opens the package.

Weak seals, leaky pouches, or inconsistent materials aren’t just aesthetic problems; they’re brand-breakers.

A reliable nutraceutical packaging machine ensures consistent seals, protects the product’s integrity, and maintains the trust your customers place in your brand.

Limited Labor, High Expectations

Many nutraceutical companies, especially growing brands and co-packers, don’t have huge packaging teams or dedicated engineers. They rely on lean operations, with employees who wear multiple hats.

Machines that are difficult to train on, prone to error, or slow to set up can become the single biggest bottleneck on the production floor.

A smart nutraceutical packaging machine should be user-friendly, intuitive, and designed to reduce training time and operator error, so your line keeps moving, even with a small team.

DTC and Subscription Channels Raise the Bar

The direct-to-consumer channel has transformed the nutraceutical industry. Brands now ship fragile, sensitive products straight to customers’ homes.

Poor packaging doesn’t just mean extra costs in returns or replacements, it damages trust. And with unboxing now part of the brand experience, packaging has to be consistent, reliable, and visually appealing.

A modern nutraceutical packaging machine needs to deliver seals that hold up in transit and presentation that meets consumer expectations.

Labeling and Traceability Requirements

This industry is regulated for a reason. Every package needs clear Supplement Facts panels, ingredient lists, and batch or lot codes for traceability. Equipment that can’t integrate with date code printers or ensure legible, consistent labeling can open you up to compliance headaches.

How the AP-140 Nutraceutical Packaging Machine Solves These Challenges

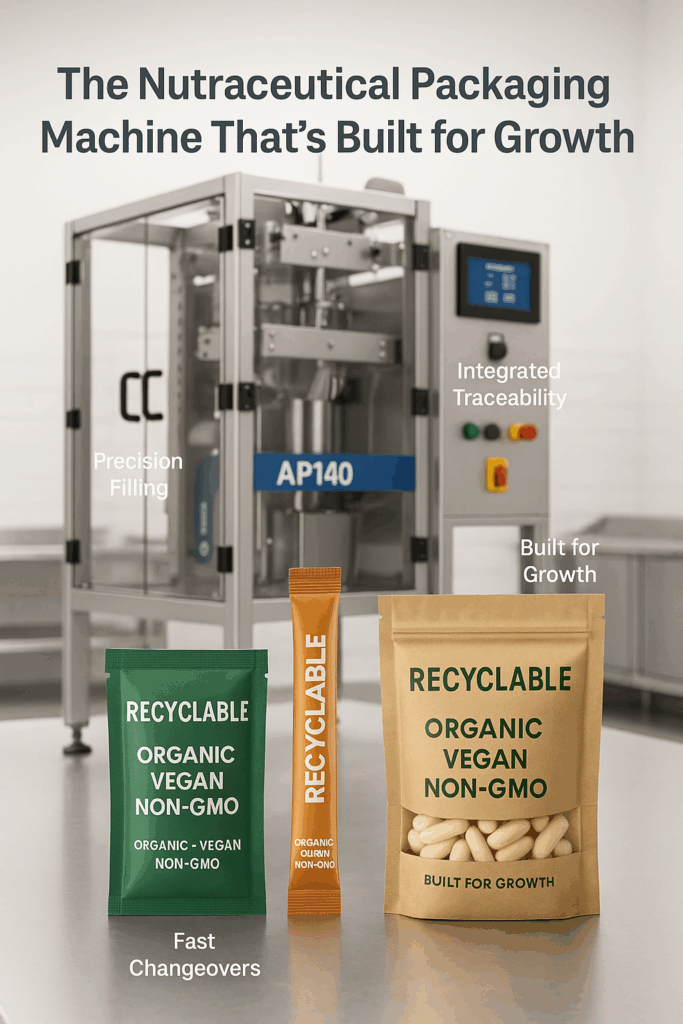

That’s exactly why Unified Flex designed the Auto Pouch Bagger AP-140 nutraceutical packaging machine to turn these common production challenges into competitive advantages.

This isn’t about adding complexity. It’s about removing friction.

Versatile Formats for Growing Brands

The AP-140 doesn’t force you to choose a single pouch style. It’s engineered to run pillow bags, 3-side seal, 4-side seal, and stick packs, all with optional tooling.

That means you can switch from single-serve wellness sachets to bulk powder refill pouches on the same line without major downtime. This nutraceutical packaging machine supports growing SKU counts, seasonal launches, and personalized nutrition trends, so you stay responsive to the market.

Precision Filling Across Product Types

Powders, liquids, granules, each product type demands precise dosing. The AP-140 integrates seamlessly with auger fillers, piston fillers, and volumetric cup fillers to ensure accuracy batch after batch.

It’s designed to reduce overfill waste and underfill complaints. For nutraceutical producers, that means better margins, fewer quality issues, and greater consumer trust.

Integrated Traceability and Labeling

Batch codes, production dates, and lot numbers aren’t optional, they’re essential for compliance and consumer safety.

The AP-140 nutraceutical packaging machine supports integrated date coding and traceability printing directly on pouches. No extra manual steps. No error-prone workarounds. Just reliable, consistent compliance baked into your production process.

Protecting Product Integrity

Product integrity can’t be an afterthought. For oxygen- and moisture-sensitive ingredients, the AP-140 offers an optional nitrogen flush to displace oxygen in sealed pouches, helping maintain potency and extend shelf life.

Consistent, high-quality seals ensure your formulation arrives as effective as it was the day it was packaged. That’s how you protect your promise to customers.

Designed for Lean, Agile Operations

Smaller nutraceutical brands or co-packers often need to run many SKUs without an army of operators. The AP-140 is modular and easy to set up, with an intuitive touchscreen interface that reduces training time. Rotatable horizontal seal jaws and smart design make changeovers faster and less prone to error, keeping your line moving even with a lean team.

Built for Smaller Batches and Growth

The AP-140 gives nutraceutical brands the flexibility to handle a variety of packaging formats and production demands. It supports everything from core product lines to new SKUs and seasonal launches, making it easier to adapt to changing consumer trends and direct-to-consumer growth. With its adaptable design and consistent performance, it keeps your packaging line ready for what’s next.

Final Thought: Formulate Boldly. Package Smartly.

In nutraceuticals, your formulation is only half the promise. The other half is keeping it effective, compliant, and appealing in the consumer’s hands.

If your packaging can’t keep up with your ambitions, your business is stuck in second gear. The AP-140 bridges that gap, delivering reliable, adaptable performance as a nutraceutical packaging machine you can count on. Watch the AP-140 in action.

Whether you’re expanding an established line or building a new wellness brand from the ground up, Unified Flex’s AP-140 delivers real-world solutions to the packaging challenges nutraceutical producers face every day.

It’s not about flashy features. It’s about a machine that works reliably, adapts quickly, and helps you keep your promise to your customers.