The Coffee Packaging Machine That Grows with Your Brand

A Boom with Bottlenecks

Coffee isn’t just a morning ritual; it’s a booming global industry with more demand, more formats, and higher expectations than ever before. From local roasters to large-scale private-label producers, coffee brands are growing their lines to meet customer needs. Whole beans, pre-ground coffee, single-serve stick packs, retail bags, and foodservice bulk orders mean today’s coffee SKUs are more varied and complex.

With that growth comes real operational pressure. It’s not enough to roast exceptional coffee. Your coffee packaging machine has to work just as hard. It needs to preserve freshness, protect the product during shipping, deliver consistent seals, and handle different bag formats without slowing production.

For many brands, the real bottleneck isn’t sourcing beans or refining blends, it’s having a coffee packaging machine that can keep up with the complexity and scale of modern production.

Real-World Packaging Challenges Facing Coffee Producers

SKU Proliferation and Changeovers

Today’s coffee producers can’t get by with a single format. The same facility may package retail-size bags, single-serve stick packs, and sample sizes, all with different weights and requirements. That SKU variety is great for sales, but tough on production.

A rigid or outdated coffee packaging machine can make changeovers a nightmare. Operators waste hours adjusting settings and troubleshooting issues. That downtime translates into lost output, higher labor costs, and delays fulfilling growing orders.

Diverse Product Forms and Flow Properties

Coffee isn’t uniform. Whole beans flow easily but are bulky and abrasive. Ground coffee can create fine dust that clings to machinery. Instant mixes and stick-pack powders often include sugar or creamers that change flow characteristics entirely.

A coffee packaging machine that can’t handle these variations will create spills, waste, uneven weights, and downtime for cleaning. Producers need equipment that adapts to the real-world variety of coffee products on the market.

DTC and Retail Shipping Demands

Direct-to-consumer sales have changed the game. Coffee brands now ship directly to customers nationwide while competing on crowded retail shelves. Packaging needs to be strong enough to survive fulfillment centers, shipping trucks, and last-mile delivery, while looking flawless when it arrives.

Weak seals or crushed bags aren’t just costly returns; they’re bad reviews and lost customers. The right coffee packaging machine helps you maintain high-quality, consistent packaging that protects your brand everywhere it goes.

Limited Labor and Training Resources

Coffee production teams are often lean, with workers cross-trained on roasting, quality, and packing. Complex, hard-to-use packaging equipment quickly becomes a bottleneck.

Your coffee packaging machine should simplify operation, not complicate it. Easy-to-train interfaces and intuitive controls ensure that any shift can run it confidently, reducing labor costs and keeping production flowing even as teams change.

Throughput vs. Quality

Coffee producers know there’s no shortcut to quality. Faster output is essential as demand grows, but speed can’t come at the expense of seal integrity or fill accuracy. Poorly sealed bags lead to stale coffee, inconsistent weights damage trust, and breakdowns disrupt schedules.

The best coffee packaging machines don’t force you to choose between speed and quality. They deliver both reliably and consistently, so you can grow your business without compromising what makes your coffee special.

How the AP-140 Solves These Coffee-Specific Demands

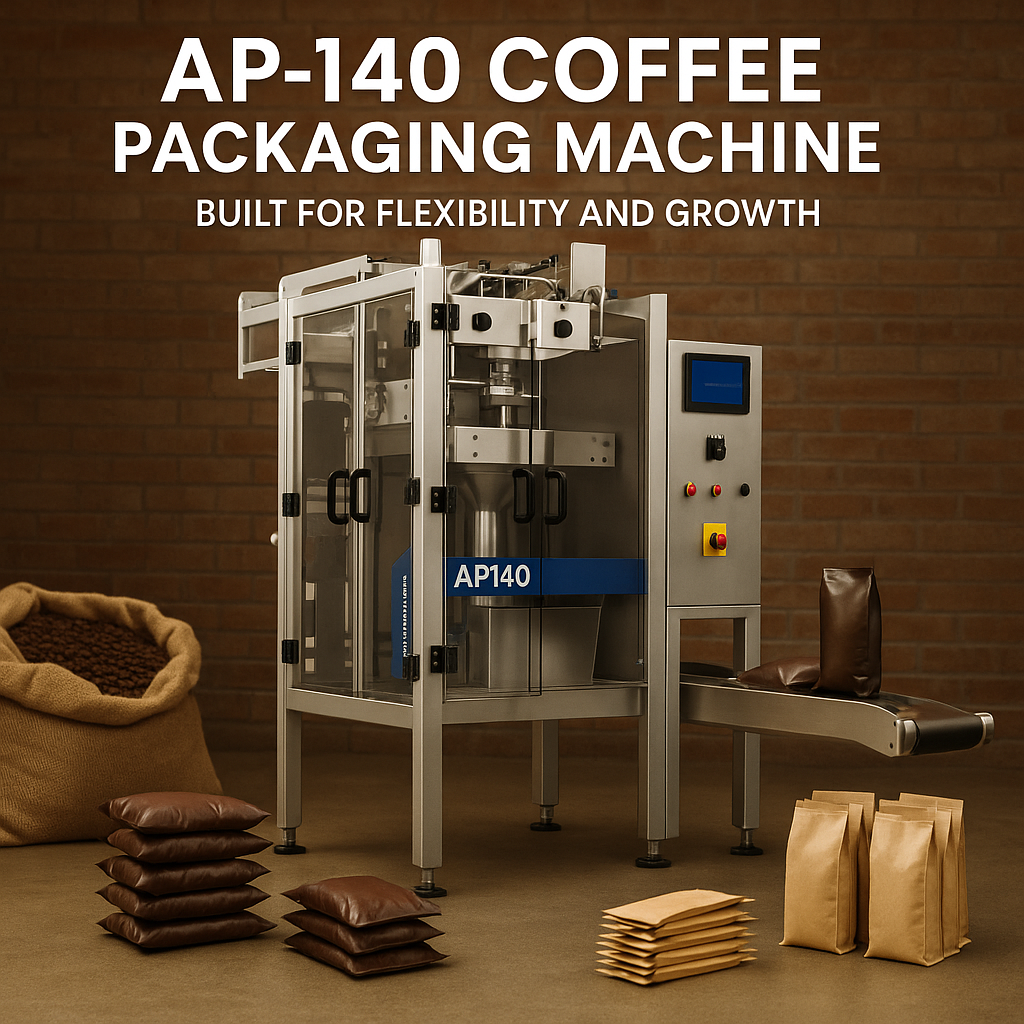

The Auto Pouch Bagger AP-140 isn’t a one-size-fits-all machine designed for a single product. It’s a versatile, real-world coffee packaging machine that adapts to your evolving lineup. From whole beans and ground coffee to instant stick packs, the AP-140 handles the variety, changeovers, and operational demands that growing coffee brands face.

Versatility for Multiple Formats

Coffee producers rarely pack just one product. The AP-140 supports pillow bags for whole beans, 3-side and 4-side seal sachets for ground coffee or samples, and stick packs for single-serve instant blends.

This flexibility means you can handle your entire SKU lineup on one machine. It’s packaging versatility that grows with your business, so you can adapt to market trends without constantly investing in new equipment.

Compatibility with Diverse Fillers

Coffee production demands flexibility in filling. Whole beans, ground coffee, and instant powder mixes all have different flow characteristics.

The AP-140 integrates seamlessly with auger fillers, piston fillers, and volumetric cup fillers. Whether you’re packing coarse single-origin beans or fine flavored instant powder, you get reliable, consistent fills without the headaches of incompatible equipment.

Real-World-Ready Design

Roasting and packing coffee isn’t a pristine, lab-like process. There’s dust from grinding, oils from beans, and constant motion on the floor. The AP-140 is built for these real-world conditions, with stainless steel contact parts that simplify cleaning and ensure food safety.

It’s also engineered for durability, using ESA-approved electronics and off-the-shelf USA components that make maintenance and part replacement straightforward and fast. Assembled in Canada, the AP-140 reflects a commitment to quality that matches the standards of specialty coffee brands.

Ease of Training and Operation

Training time is precious. Staffing is tight. The AP-140 was designed to be easy to learn and operate, featuring a 7” touchscreen HMI and PLC controls that simplify setup, troubleshooting, and daily operation.

This user-friendly approach reduces reliance on highly specialized operators and helps ensure consistency across shifts. When your team can run the packaging line confidently, production stays smooth, even during peak demand.

Efficiency Benefits That Add Up

The AP-140 isn’t just about convenience. It delivers real operational and financial benefits:

- Lower labor costs through faster training and fewer errors.

- Reduced waste from better seals and consistent fills.

- Faster time to market for new SKUs and seasonal launches.

- Improved throughput to meet rising order volumes.

- Scalability that supports your brand’s growth, not fights against it.

It’s a coffee packaging machine that pays for itself in efficiency, consistency, and customer satisfaction.

More Packaging Solutions from Unified Flex

While the Auto Pouch Bagger AP-140 is perfect for many coffee production needs, Unified Flex provides a complete range of packaging solutions. Whether you need vertical form fill seal (vffs) machines, stand-up pouch baggers, or sachet machines Unified Flex has the right solution for every packaging challenge.

Final Thought: Roast Great, Package Smarter

Roasting exceptional coffee is an art. Delivering it fresh, beautiful, and consistent to your customer’s door is a science. The Auto Pouch Bagger AP-140 bridges that gap.

It’s built for real-world coffee production: intuitive to use, flexible enough for growing SKU complexity, compatible with diverse fillers, and designed to make training faster and easier. It’s not about flashy promises, it’s about a packaging machine that works as hard as you do to protect your brand, your product, and your reputation.

Ready to see what the AP-140 can do for your roastery?