Optimal Pet Food Packaging Solutions

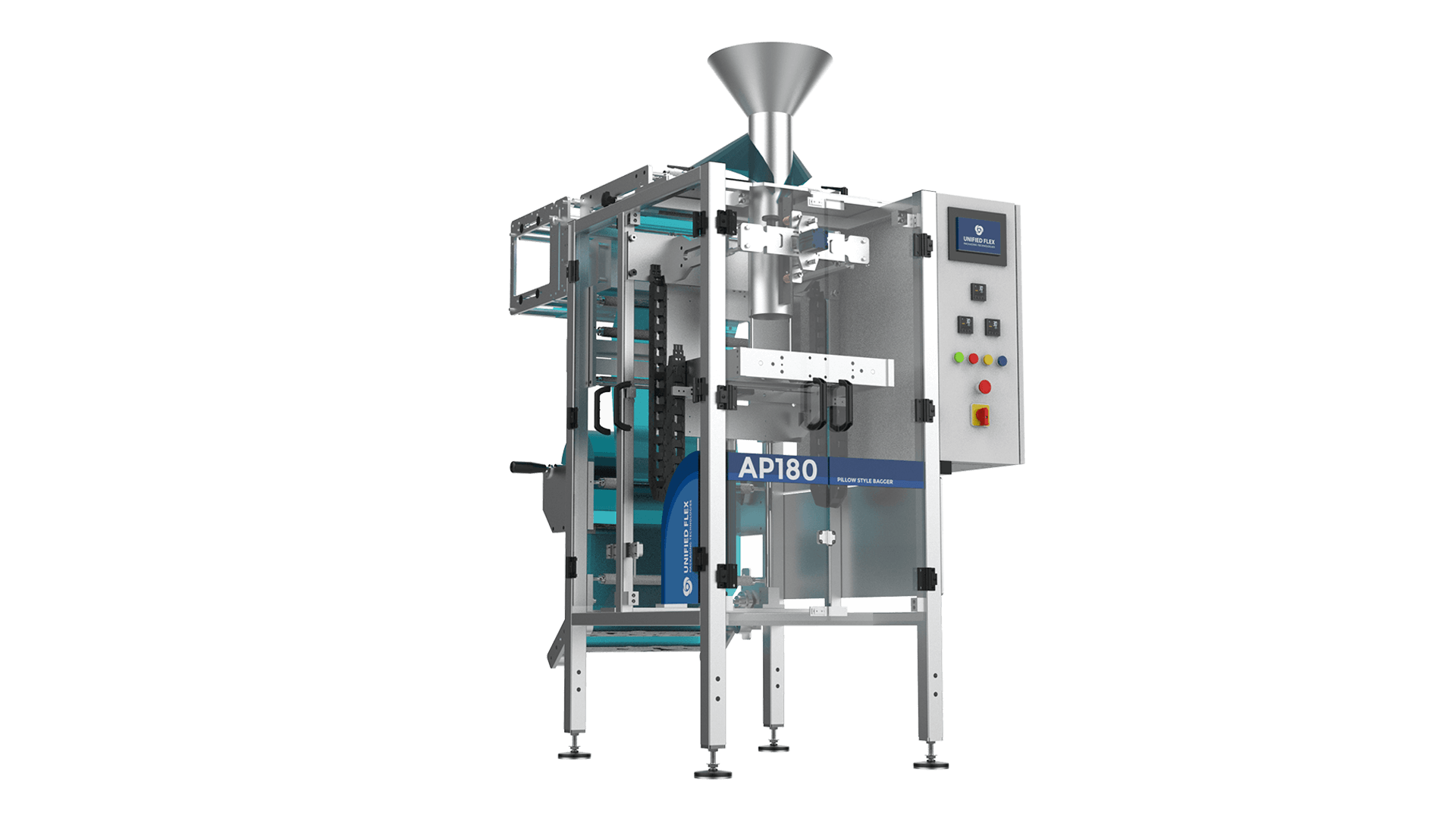

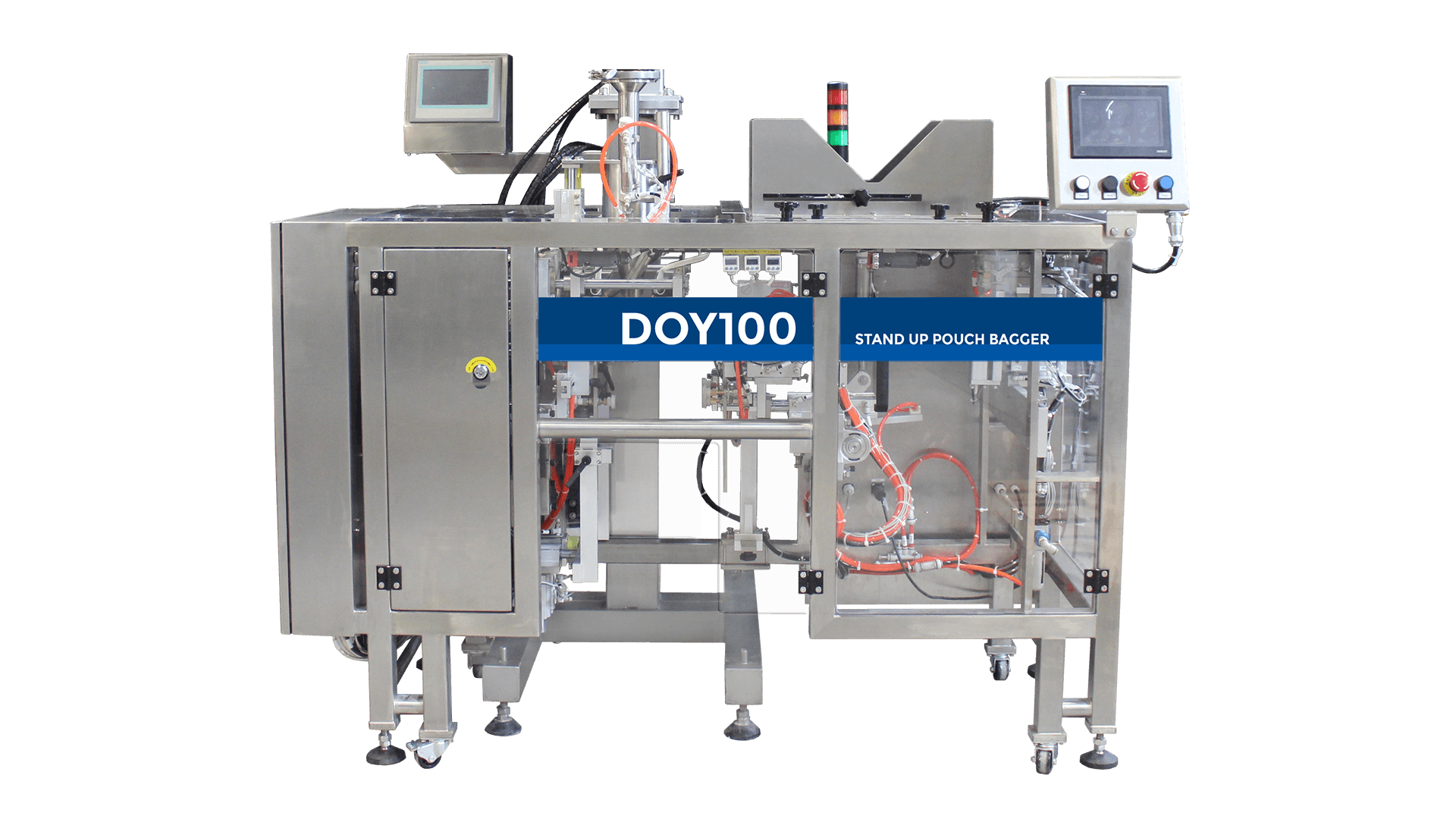

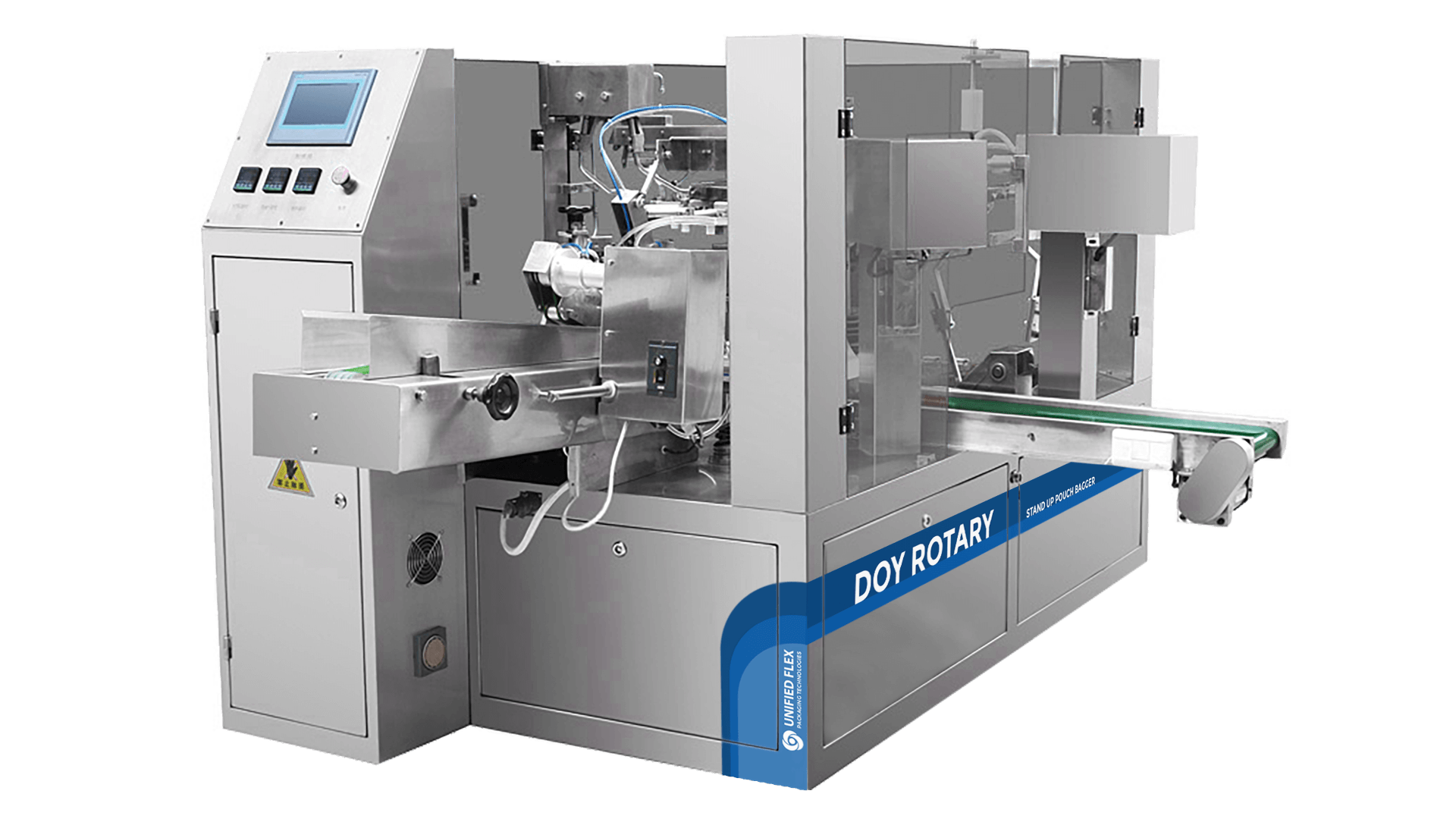

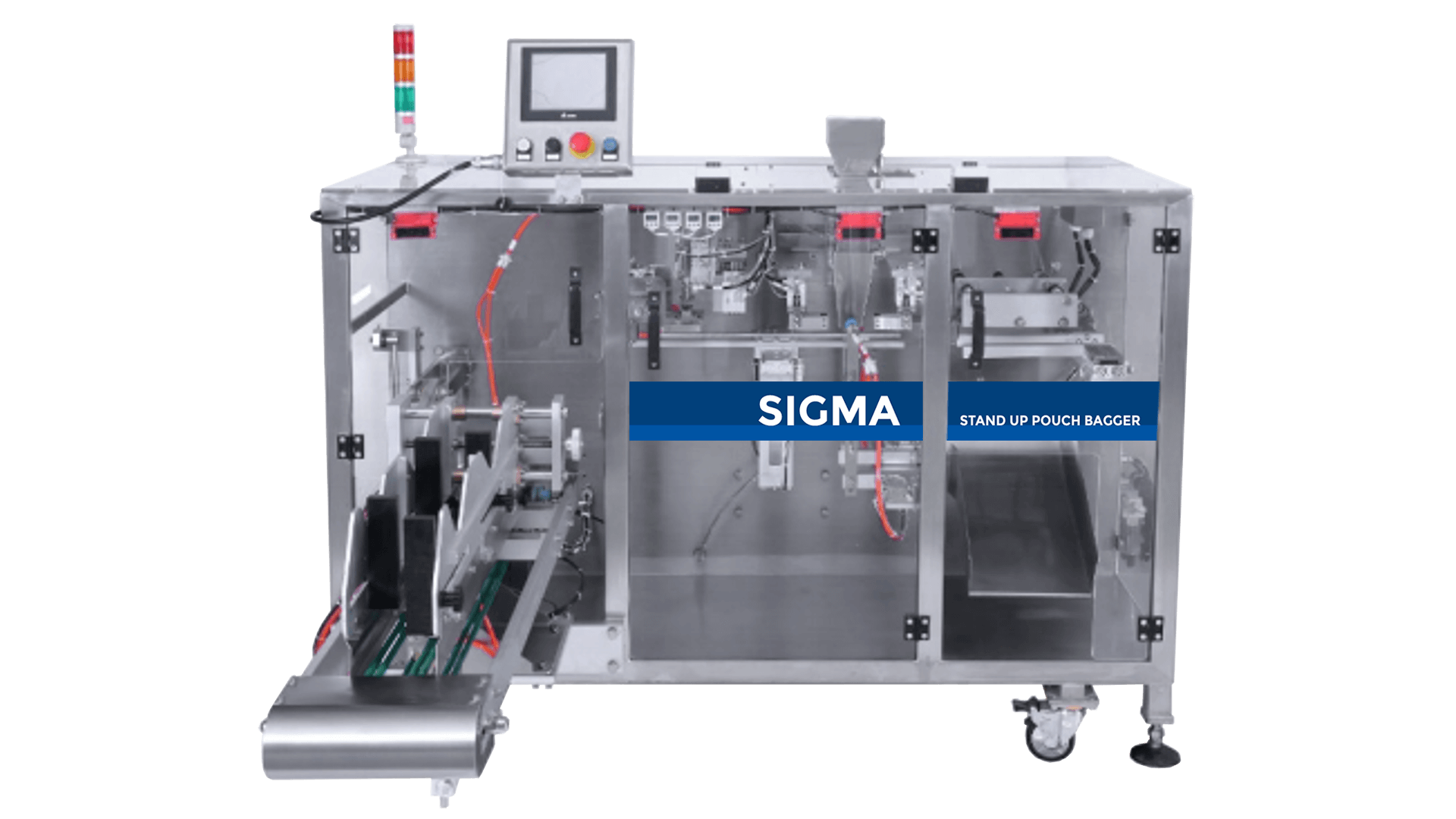

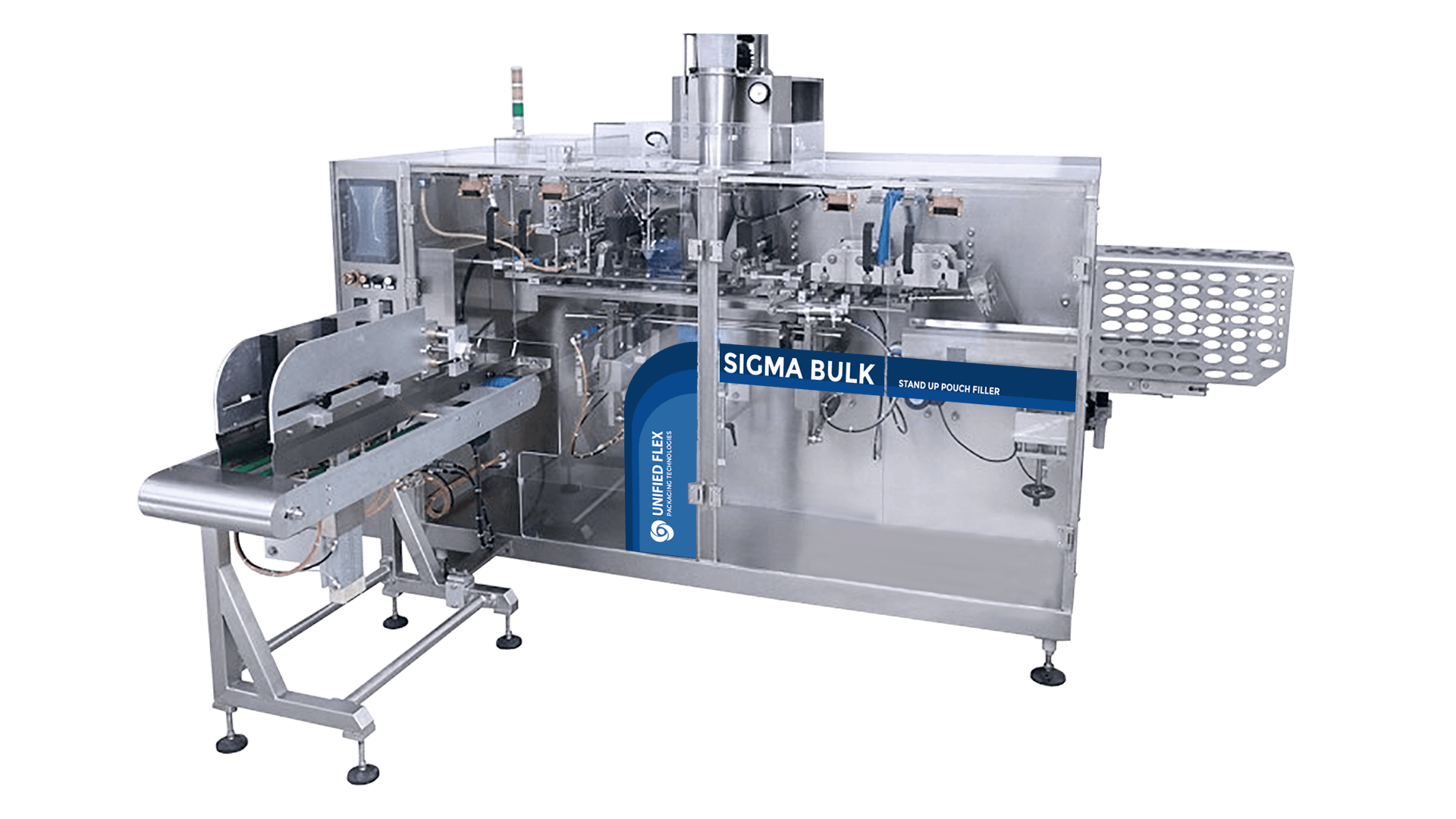

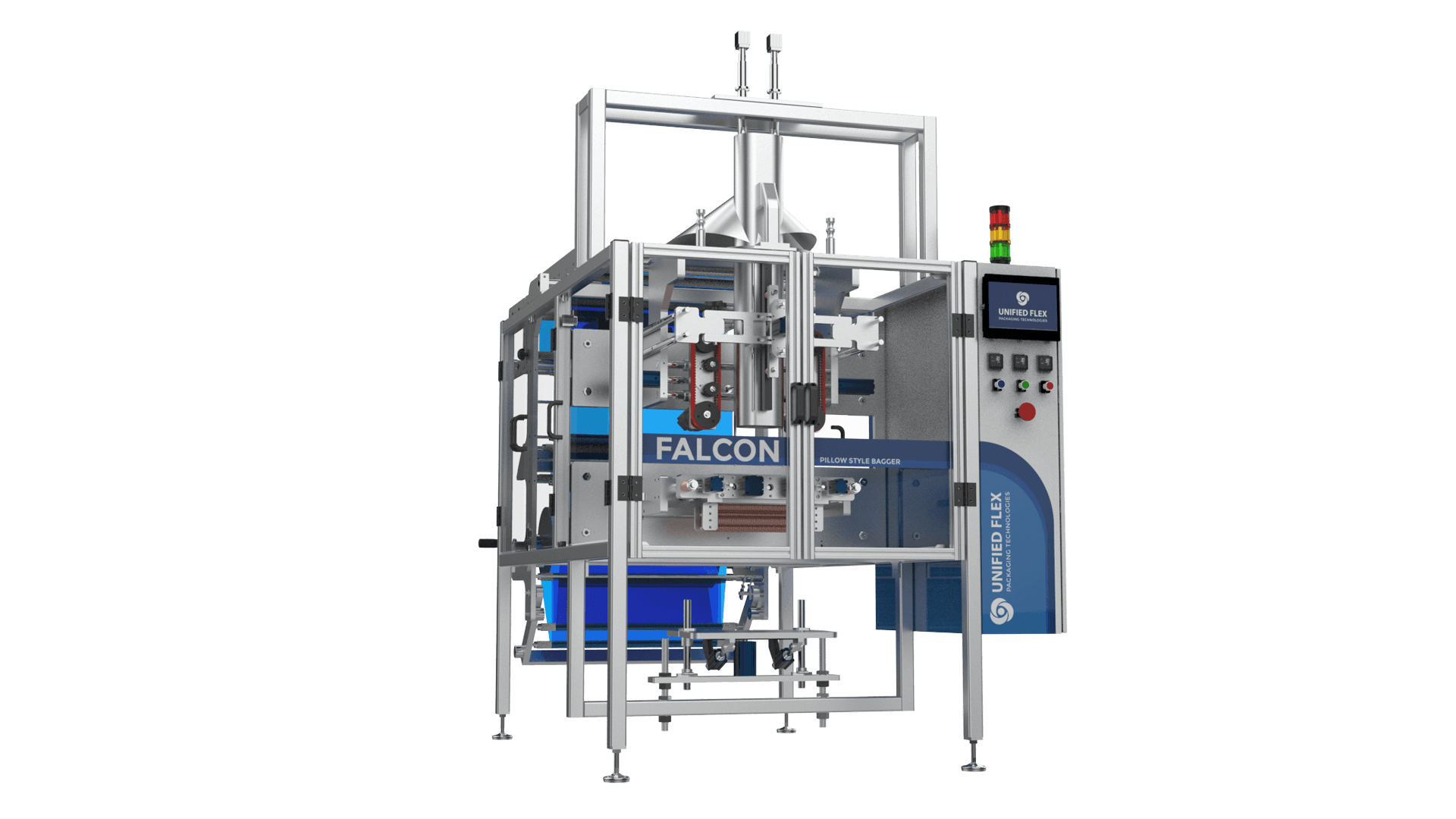

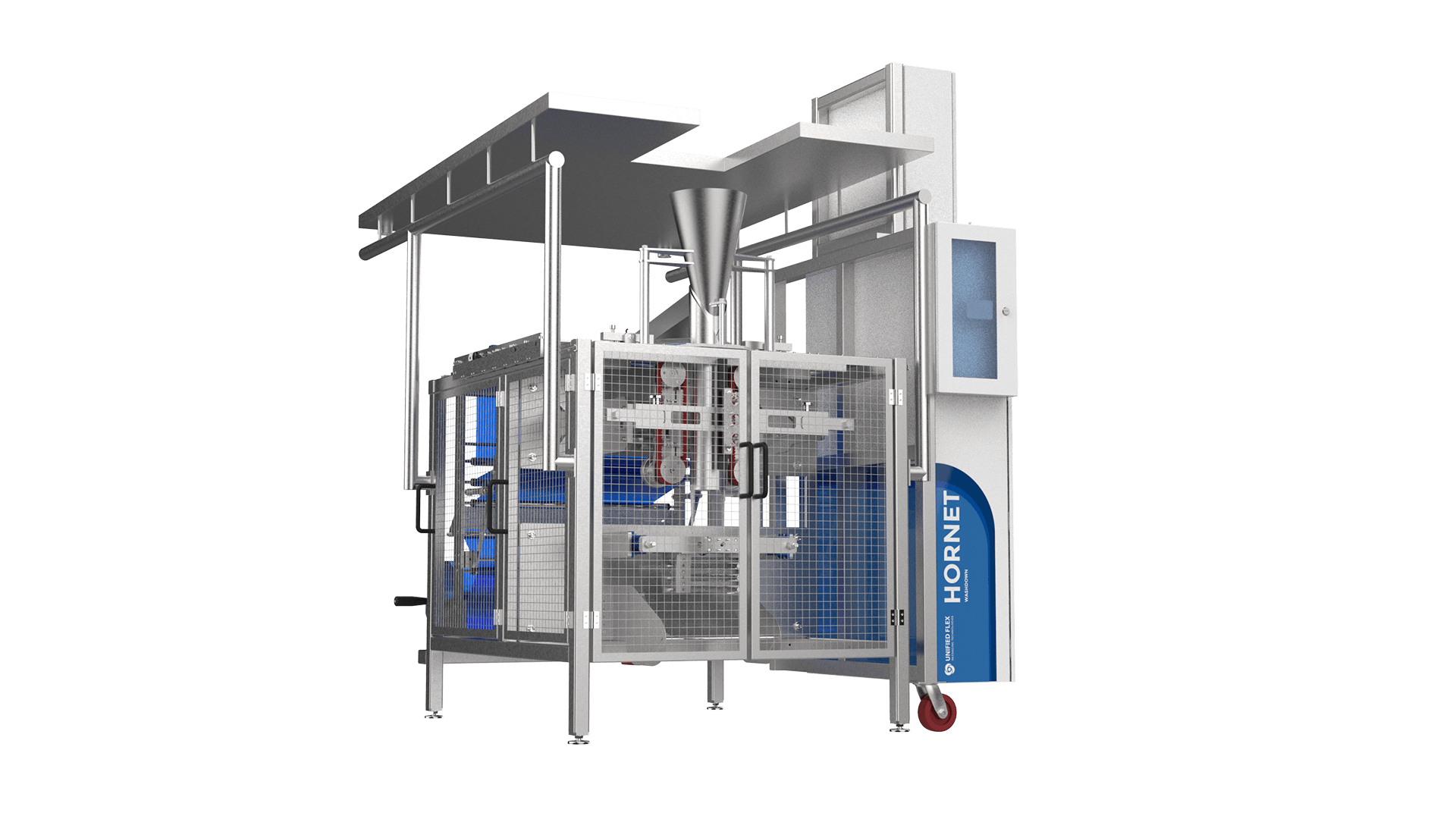

Unified Flex is making its mark on the pet food industry with efficient and precise packaging solutions. From kibble to treats to wet food, our cutting-edge pet food packaging machines and flexible packaging options ensure optimal product preservation, convenience, and shelf appeal, elevating your brand to new heights.

You can count on Unified Flex to help you with whatever your pet food challenge may be, including selecting the right machine for the job, selecting the optimal packaging materials such as preformed bags, packaging film, or, creating a customized solution to cater to pet owners.

Contact us now to elevate your packaging for pet foods.