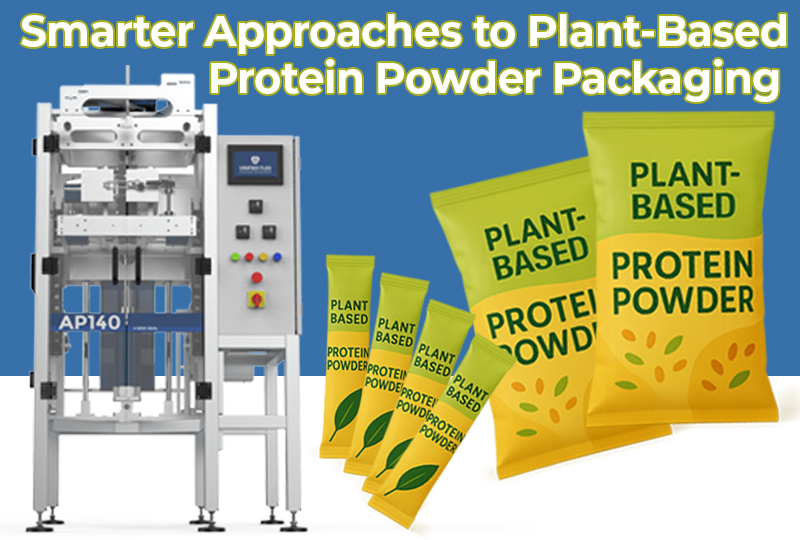

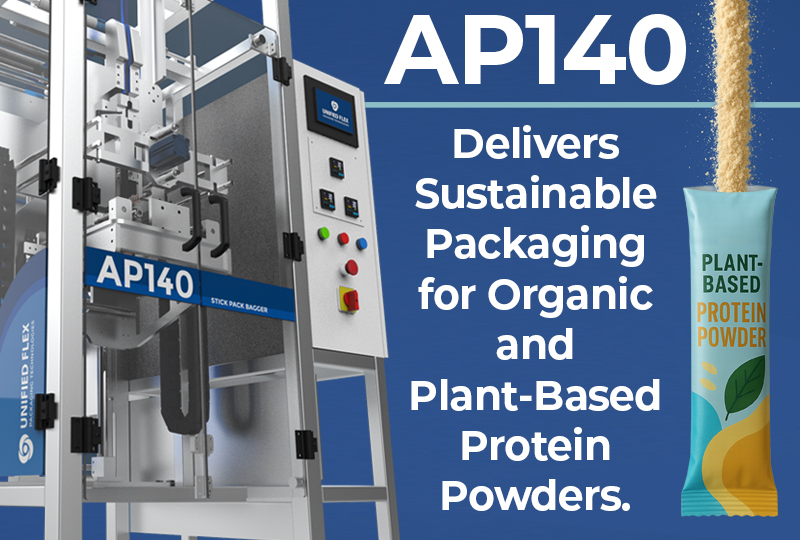

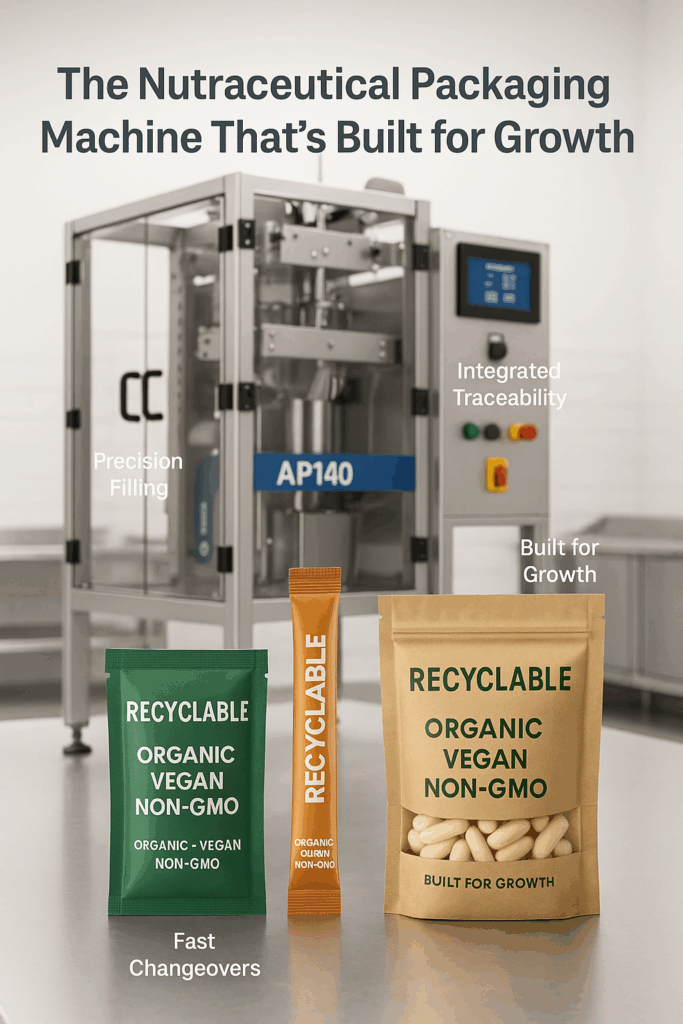

The AP-140 nutraceutical packaging machine is designed for brands that need reliable, versatile packaging solutions. Handle powders, liquids, and gummies with precision, meet compliance requirements, and keep production running smoothly, even with growing SKU complexity. Learn how it supports your brand’s growth.