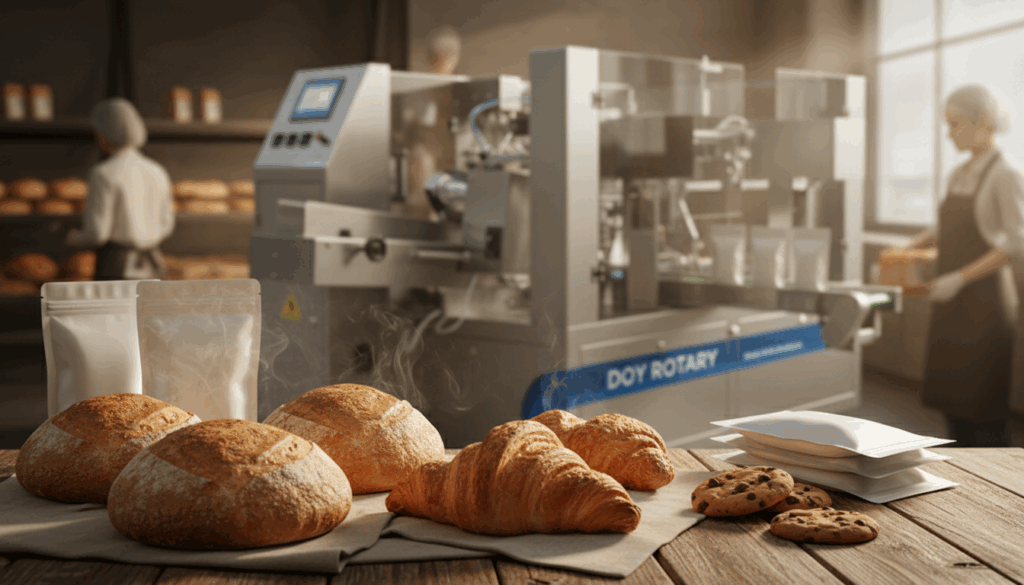

Want your cookies to stay crunchy, your bread soft, and your muffins safe on the shelf? Bakery packaging machines do much more than just wrap products; they seal in freshness, protect delicate treats, extend shelf life, and keep everything looking bakery-perfect. In this blog, we’ll show you how these machines work their magic and why they’re a must-have for every growing bakery business.