How Do Bakery Packaging Machines Keep Products Fresh and Intact?

Who doesn’t love the smell of fresh bread, soft muffins, or crunchy cookies right out of the oven? The aroma alone is enough to make anyone’s mouth water. But here’s the real challenge: once those goodies leave the bakery, how do you make sure they stay as fresh, tasty, and safe as they were on day one?

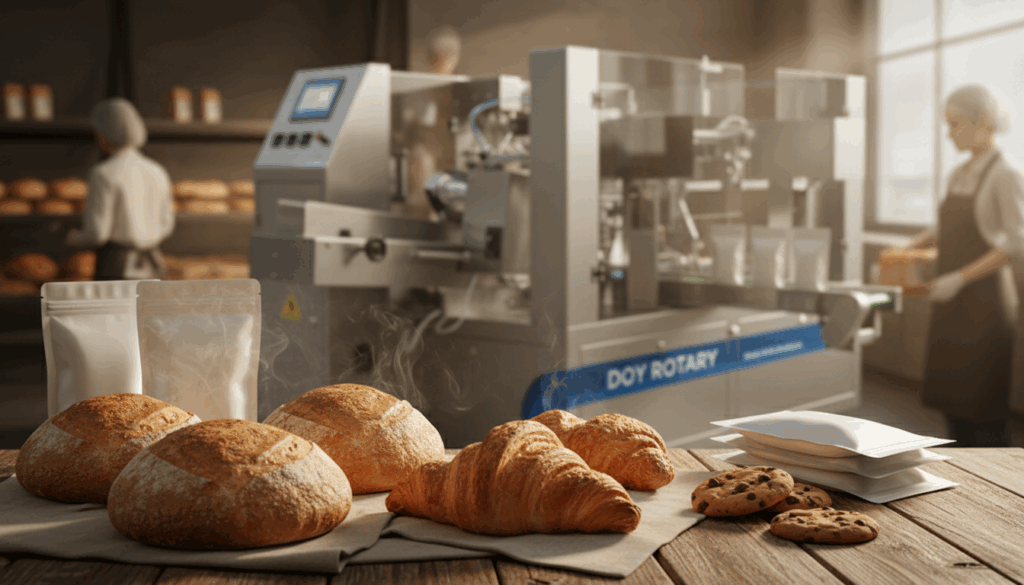

That’s where the bakery packaging machine steps in. These smart machines aren’t just about wrapping food in plastic or sealing it in a bag. They’re designed to protect delicate products, lock in freshness, and keep everything looking as good as it tastes.

Let’s break it down and see how these machines work their magic.

Why Freshness and Protection Matter in Bakery Packaging

Imagine buying a pack of cookies only to find them soggy or broken inside. Or cutting into a loaf of bread that already tastes stale. Disappointing, right? Freshness and product safety aren’t just about taste; they’re about customer trust.

Bakery items are extra sensitive because they’re usually soft, crumbly, and easily spoiled. Exposure to air, moisture, or even just too much handling can ruin them. That’s why bakeries rely on packaging machines that do the job quickly, neatly, and consistently.

With over 17 years of experience, Unified Flex understands the challenges faced by bakeries. Our team of professionals helps you integrate packaging machines and solutions that fit perfectly into your production line, ensuring your products always reach customers in pristine condition.

How Bakery Packaging Machines Keep Products Fresh & Safe

Here are the main ways a bakery packaging machine protects your baked goods:

Airtight Sealing

The biggest enemies of bakery freshness are air and moisture. Air carries oxygen, which causes food to go stale faster. Moisture, on the other hand, can make cookies soggy or bread moldy. Bakery packaging machinery solves this with airtight sealing. Once a product is placed in a bag or pouch, the machine seals it tightly, creating a barrier between the food and the outside world.

Advanced Freshness Techniques

Some advanced machines go a step further with special packaging methods like nitrogen flush, vacuum sealing, and degassing. These might sound technical, but they’re actually quite simple. For example, nitrogen flush replaces oxygen with nitrogen to keep snacks fresh, vacuum sealing removes air to protect products from moisture and spoilage, and degassing allows freshly roasted coffee to release carbon dioxide without letting air in. Together, these methods help products stay fresher, tastier, and safer for longer.

Gentle Handling for Delicate Goods

Bakery products are often fragile, think of macarons, muffins, or puff pastries. Even the slightest squeeze or drop can ruin their shape. Packaging machines are designed with this in mind.

They use gentle conveyor belts, soft drop systems, or vacuum suction tools to move items without crushing them. It’s like having careful hands that never get tired. This way, your cookies don’t arrive at the store in pieces, and your bread doesn’t get squashed.

Strong, Secure Packaging Styles

Not all bakery products are the same, so machines offer different packaging styles:

- 3 Side Seal Bag

- 4 Side Seal Bag

- Block Bottom Bag

- Box Pouch

- Doy Rim Style Bag

- Flat Bottom 4 Corner Bag (or Flat Bottom Box Pouch)

- Pillow Bag

- Pillow Bag with Side Gussets

- Quad Seal Bag

- Stand Up Pouch

These packaging options not only look appealing but also provide structure and support so the product doesn’t break or crumble. It’s packaging that’s both practical and attractive!

Protection from Contamination

Cleanliness is just as important as freshness. Bakery packaging machines reduce the need for human hands to touch the food, lowering the risk of contamination.

From start to finish, the process is automated, and products move from the oven to the packaging line with minimal contact. For customers, that means peace of mind knowing their treats are safe to enjoy.

Fast and Consistent Packaging

Speed matters in bakeries. Freshly baked goods need to be packed quickly before they start losing moisture. Packaging machines are built for high speed and efficiency.

They can pack hundreds of cookies or bread loaves per hour, much faster than manual labor. And the best part? They do it consistently. Every bag is sealed the same way, with no room for error.

Extending Shelf Life

The right packaging can add days (sometimes even weeks) to a product’s shelf life. That’s a game-changer for bakeries that supply to supermarkets or export goods.

Due to sealing technology, oxygen barriers, and advanced methods like nitrogen flush, vacuum sealing, and degassing, a bakery packaging machine helps keep products tasting fresh longer. That means less food waste and happier customers.

Partner with Unified Flex for Fresher, Safer Packaging

Ask yourself: are your bakery products reaching your customers in the same fresh, perfect condition as when they left your oven? If the answer is no, it’s time to explore Unified Flex’s bakery packaging solutions.

To help bakeries like yours, we offer a range of high-performance bakery packaging machines:

- Sachet Machines for Baked Goods–40 to 1000 bags per minute

- Vertical Form Fill Seal Machines for Baked Goods–40 to 1000 bags per minute

- Stand-Up Pouch Bagging Machines for Baked Goods–15 to 40 bags per minute

Investing in the right packaging solution doesn’t just protect your products; it protects your reputation. Keep your baked goods fresh, intact, and irresistible, and give your customers a reason to keep coming back for more.

Putting It All Together

If you want your baked goods to reach customers fresh, intact, and looking perfect, bakery packaging machinery is essential. They help:

- Lock in freshness with airtight seals.

- Protect delicate items during handling.

- Maintain consistency and portion sizes.

- Reduce waste and human error.

- Improve hygiene and food safety.

- Offer professional, brand-ready packaging.

For bakery business owners, investing in our machines is not just about convenience; it’s about improving product quality, customer satisfaction, and ultimately, your reputation.