Solving Seafood, Poultry, and Meat Packaging Challenges with the Right Meat Packaging Machine

Seafood, poultry, and meat packaging are not for the faint of heart. These products sit at the very edge of the cold chain, where freshness is fragile and safety is non-negotiable. A single misstep, a seal that doesn’t hold, a corner of a machine that isn’t fully sanitized, can ripple through production, distribution, and retail.

In this world, every detail matters, and at the heart of it all is the meat packaging machine: the workhorse that shapes, seals, and protects the most high-risk products on the line. When it performs perfectly, it’s almost invisible. When it falters, the entire operation feels the impact.

Understanding the challenges is the first step toward solving them. Here’s a closer look at the obstacles processors face today and how a new generation of washdown-ready machines is built to meet them head-on.

Challenges That Keep Protein Processors Up at Night

Seafood, poultry, and meat share a common reality: they are inherently risky products. Fresh or frozen, they demand precision, speed, and strict sanitation. But the realities of production make this easier said than done.

The Complexity of Fresh and Frozen

Fresh proteins require airtight packaging that keeps oxygen out and extends shelf life, while frozen proteins need strong barriers to prevent freezer burn and moisture loss. Many plants run both formats on the same floor, or even the same line. Switching between them creates a constant risk of error, especially when changeovers are slow or manual.

Sanitation Windows That Steal Production Time

In a high-risk environment, washdowns aren’t optional; they’re essential. But they’re also one of the biggest sources of downtime. Many packaging machines were never designed for today’s sanitation standards. Hard-to-reach areas, fragile components, and complex teardown processes mean crews spend hours cleaning and even then, may miss hidden hotspots where bacteria can linger.

Every extra minute spent cleaning is a minute lost to production. But cutting corners isn’t an option when regulators and retailers demand flawless hygiene.

Seal Integrity Under Pressure

Flexible packaging has become the format of choice for seafood, poultry, and meat, especially pillow bags and eurohole formats. But thinner, more sustainable films are less forgiving. If a seal isn’t perfect, the result can be catastrophic: leaks, bloated packs, rejected shipments, or, worst of all, a safety issue that triggers a recall.

Maintaining consistent seals becomes even harder when product temperatures fluctuate or condensation builds up in the cold, humid environment of protein plants.

SKU Proliferation

Today’s grocery aisles are overflowing with variety: single-serve seafood portions, family-sized poultry packs, premium meat cuts, and more. Each product comes with its own packaging specs. Frequent changeovers are inevitable, and every one of them creates a moment of vulnerability for the line. When changeovers are slow or unpredictable, they can derail an entire shift.

Why These Challenges Matter More Than Ever

The stakes aren’t just operational, they’re existential. A single recall can cost millions and permanently damage a brand’s reputation. Retailers are less forgiving than ever, demanding compliance, consistency, and sustainability. And with margins in protein processing measured in pennies per pound, downtime and waste add up fast.

It’s no wonder that many processors feel trapped between two competing priorities:

- Protecting safety and compliance, which requires frequent, thorough cleaning and rigorous checks.

- Protecting output and margins, which requires speed and uptime.

The problem? Most packaging machines force processors to choose between the two.

The Solution: A Meat Packaging Machine Built for Protein Reality

What if your packaging machine didn’t just survive the challenges of protein production—but actually made them easier to manage?

Modern, washdown-ready machines are built with seafood, poultry, and meat in mind. They take the pain points of the protein world and solve them at the design level.

Sanitation Without the Downtime

The right meat packaging machine embraces sanitation as part of its DNA. Smooth, drainable surfaces eliminate hiding spots for bacteria. IP69K-rated components withstand high-pressure cleaning day after day. And open, 360-degree access means sanitation teams can reach every inch of the machine without excessive teardown or special tools.

Instead of dreading washdowns, crews can complete them quickly and confidently, then get the line back into production faster than ever before.

Consistent Seals on Challenging Films

Protein packaging lives and dies by seal integrity. Servo-controlled motion and digital temperature management keep seals airtight and repeatable, even when humidity and product temperature fluctuate. This is especially critical for flexible pillow bags and eurohole formats, which dominate today’s seafood, poultry, and meat displays.

With precise control, processors can meet retailer expectations while minimizing waste and rework.

Faster, Cleaner Changeovers

Modern machines make SKU diversity less painful. Tool-less changeovers allow operators to switch between bag sizes and product types in minutes, not hours. Automated alignment and print-mark registration keep graphics where they belong without endless fine-tuning. The result: more SKUs, less disruption.

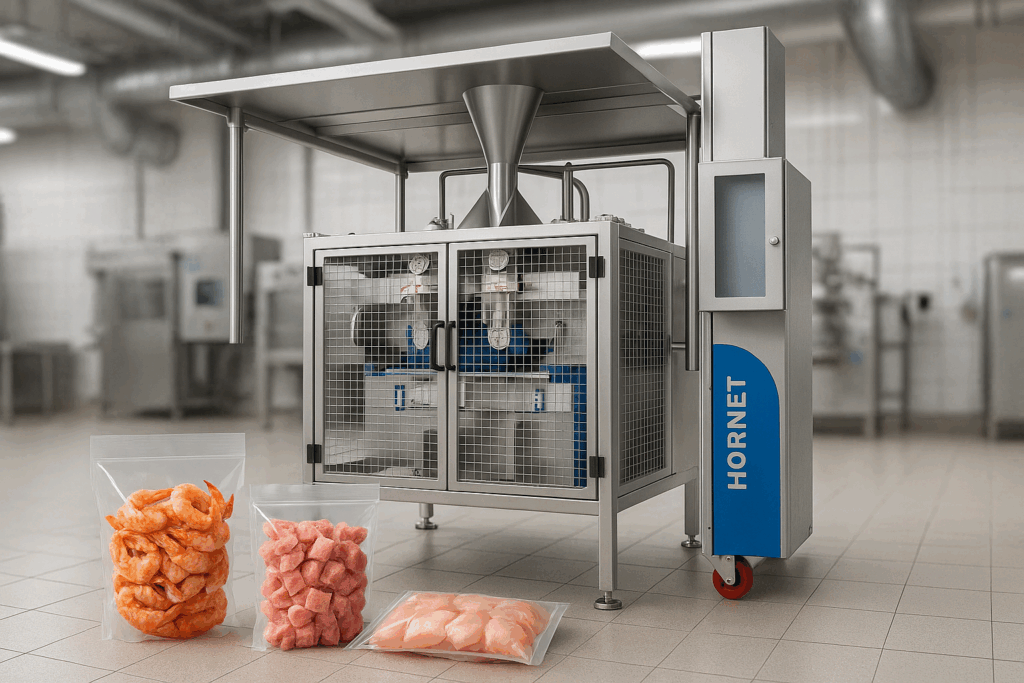

Meet the Hornet Washdown: A Meat Packaging Machine Designed for the Cold Chain

The Vffs Vertobagger Hornet Washdown is more than just another machine; it’s a rethink of what seafood, poultry, and meat packaging should be. Designed specifically for the cold, humid, high-risk environments of protein plants, it tackles the challenges that have plagued processors for years.

- Full washdown capability: IP69K-rated components with 360-degree accessibility for cleaning and maintenance.

- 360-degree visibility: Every surface is accessible, so no corner is left uncleaned

- Tool-less forming collar changes: Switch between SKUs quickly and safely

- Precision control: Servo-controlled pulling belts and jaws for perfect seals, even on thin, flexible films

- Retail-ready formats: Supports pillow bags and pillow bags with euroholes for flexible protein packaging.

- Reliable throughput: Speeds of up to 60 bags per minute to keep production moving

With the Hornet Washdown, processors no longer have to choose between sanitation and uptime. It delivers both, turning washdowns from a necessary evil into a competitive advantage.

The Payoff for Seafood, Poultry, and Meat Processors

When your packaging machine is built for your reality, everything changes:

- Sanitation windows shrink, freeing up hours of production time each week.

- Recalls and rejected shipments become less likely thanks to airtight, consistent seals.

- Changeovers stop derailing schedules, allowing you to respond to market demand quickly.

- Operators spend less time troubleshooting and more time producing.

Most importantly, the line becomes predictable; a rare gift in an unpredictable industry.

Final Thoughts

Seafood, poultry, and meat processing will never be easy. The products are too delicate, the regulations too strict, and the cold chain too complex. But with the right equipment, these challenges don’t have to hold you back.

A meat packaging machine like the Hornet Washdown doesn’t just make packages. It creates the conditions for safety, efficiency, and growth. It turns every washdown, every seal, and every changeover into an opportunity to protect both your product and your bottom line.

In a world where the stakes are this high, your packaging machine can’t just survive the pressure; it has to set the standard.