Washdowns Without Waste: Rethinking the Meat, Cheese, & Dairy Packaging Machine for the Cold Chain

In dairy, meat, and cheese production, packaging isn’t just about moving product into bags. It’s about protecting freshness, proving compliance, and keeping the cold chain intact. And in this unforgiving environment, every minute counts.

When washdowns stretch into hours, production stops cold. When changeovers take half a shift, schedules slip. When seals fail, shelf life shortens and waste mounts. None of this looks dramatic on a balance sheet, but every inefficiency chips away at margins producers can’t afford to lose.

That’s why the conversation around the modern meat, cheese, & dairy packaging machine is changing. Speed alone isn’t the measure anymore. Producers need systems that withstand sanitation, adapt to SKU fragmentation, and deliver airtight seals that extend shelf life.

The Hidden Cost of Sanitation

Hygiene is non-negotiable. Dairy, meat, and cheese producers operate under some of the strictest food safety standards in the world. But most legacy machines weren’t designed with full washdown in mind.

That gap shows up on the floor. Operators spend hours disassembling and scrubbing. Bearings corrode after repeated exposure. Components wear down under high-pressure rinses. Each cleaning cycle stretches longer than planned, and uptime shrinks.

It’s a hidden cost few producers calculate, but it’s measured in lost output every week. A machine built for washdowns with stainless steel assemblies, IP69K-rated components, and accessible forming collars changes that math. Sanitation becomes routine instead of a bottleneck, and producers reclaim the hours that used to disappear into downtime.

Downtime That Drains Margins

Not all downtime looks like a full breakdown. Often it’s the slow bleed: changeovers that eat into a shift, belts that slip out of alignment, seals that vary just enough to require rework.

In high-volume dairy packaging, those interruptions add up quickly. They translate into wasted film, lost product, and operators stuck troubleshooting instead of producing.

That’s why modern packaging machines emphasize precision and ease. Servo-driven controls regulate pulling belts and horizontal seals. Digital temperature systems hold consistent heat for every run. Tool-less forming collar changes make product transitions quick and reliable.

These aren’t luxuries, they’re operational necessities. Because in categories where margins are razor-thin, minutes reclaimed are profits protected.

Shelf Life as Strategy

In perishables, shelf life is more than a technical specification. It’s a competitive advantage.

Retailers push for longer freshness windows to reduce markdowns. Consumers expect quality without preservatives. Producers need a product that can survive transport and still deliver on the shelf.

Packaging sits at the heart of this challenge. A weak seal shortens shelf life, risks safety, and undermines trust. Strong, repeatable seals extend freshness and protect contracts.

That’s why the most effective meat, cheese, and dairy packaging machines aren’t just fast; they’re precise. Servo-driven sealing jaws keep every seal uniform. Features like ultrasonic sealing, nitrogen flush, and degassing valves enable modified atmosphere packaging (MAP), giving products extra days without additives.

In dairy, meat, and cheese, those extra days translate directly into stronger retailer relationships and less waste on the floor.

Flexibility Without Chaos

Product portfolios have exploded. A dairy plant might run single-serve drinkables, family-sized pouches, and seasonal SKUs all in one week. Cheese producers juggle shredded bags, resealable bags for slices, and snack packs. Meat lines package MAP-ready, portion-controlled, resealable bags.

Older machines struggle under this pressure. Every format change feels like a reset. Every adjustment slows the line.

A modern packaging system must adapt to multiple bag types and sizes on one line — from pillow bags, gusseted bags, and Eurohole formats to specialty options like block bottoms, quad seals, or resealable zippers. With the right optional tooling, producers can configure the machine to match their product mix and customer demands. The benefit isn’t just variety. It’s the ability to serve retail, foodservice, and e-commerce channels without investing in redundant lines.

Flexibility doesn’t have to mean downtime. It just has to mean smarter engineering.

Operator-Centric Design

Packaging machines don’t run on spec sheets. They run on people.

And in a labor market defined by high turnover and operator shortages, usability has become as important as speed. Complex setups and inaccessible parts create bottlenecks. A system that can’t be mastered quickly is a system that slows production.

That’s why design choices matter. A large, intuitive touchscreen makes operation straightforward. Quick-change belts and self-aligning assemblies reduce training time. Click-to-order spare parts keep maintenance simple. And 360-degree access means no one has to fight the machine during washdowns.

Machines built for operators, not just engineers, keep lines consistent across shifts and reduce the risk of downtime from human error.

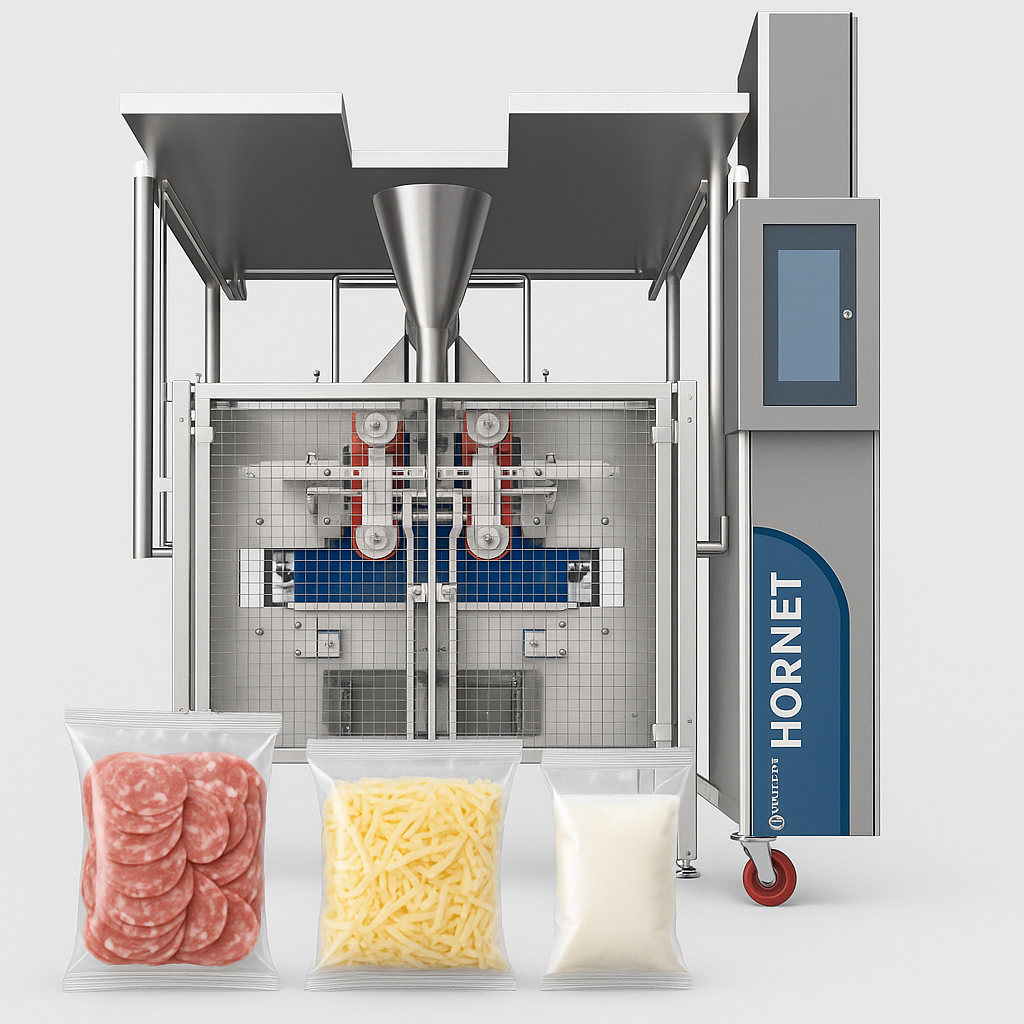

Cold Chain Confidence with the Hornet Washdown

All of these realities, sanitation, downtime, shelf life, SKU diversity, and labor, converge on one truth: producers don’t just need packaging machines. They need packaging machines designed for the cold chain.

That’s what sets the Vertobagger Hornet Washdown apart. Built with stainless IP69K-rated components, servo-driven precision, and tool-less assemblies, it was engineered around the daily demands of dairy, meat, and cheese producers. It runs multiple formats, delivers consistent seals, and makes washdowns routine instead of disruptive.

In other words, the Hornet Washdown isn’t about bells and whistles. It’s about giving producers time back. Time in faster sanitation. Time in quicker changeovers. Time in fewer reworks and wasted bags.

Because in the cold chain, time is the one thing you can’t get back.

Want to see what a Hornet Washdown dairy packaging machine could mean for your operation?