Packaging machines for gels and liquids are designed to provide secure sealing, efficient filling, and flexible packaging options. The most common types include:

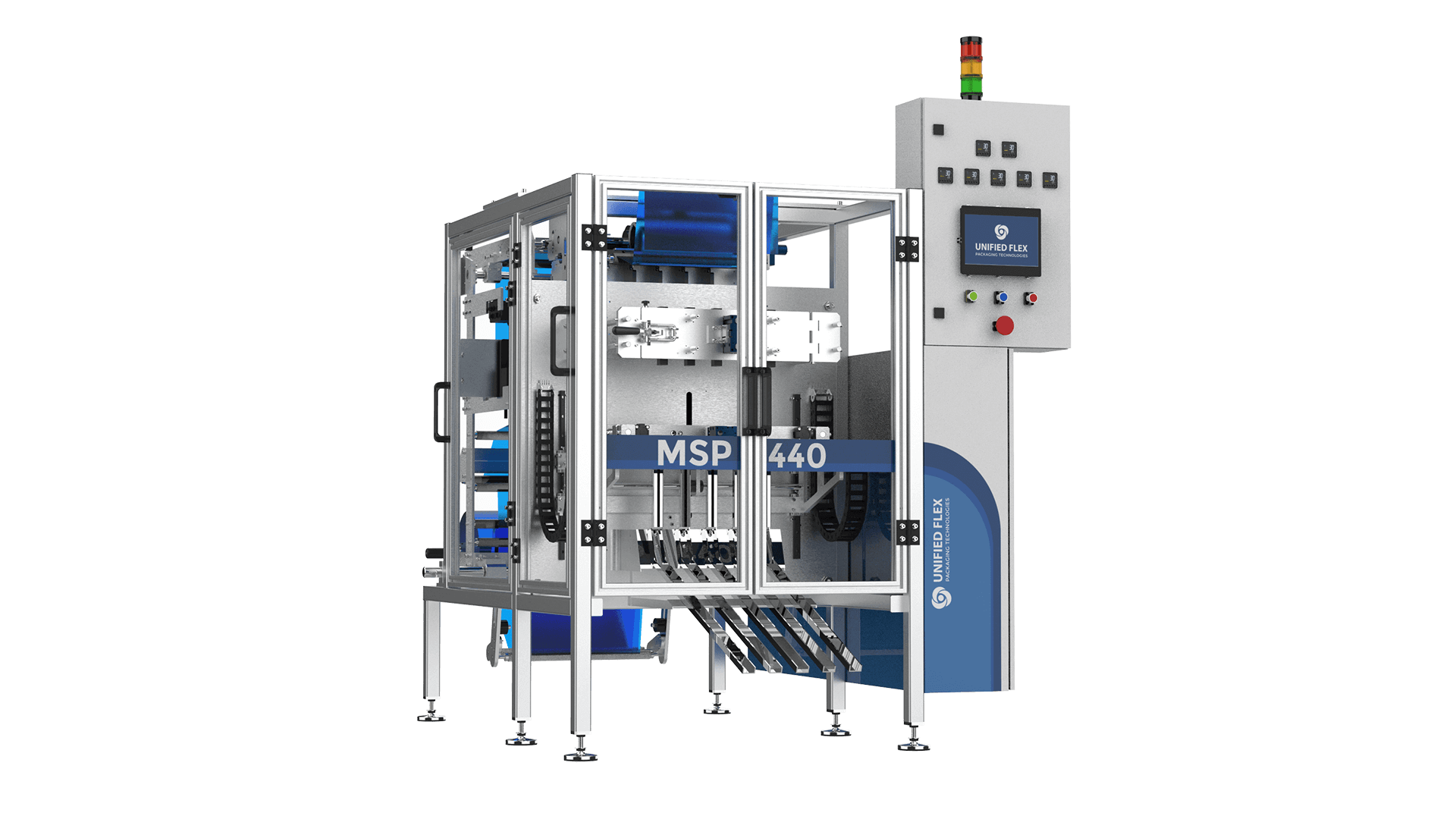

1. Stick Pack Machines

Stick pack machines produce narrow, single-serve pouches, often used for energy gels, flavored syrups, and liquid supplements. These machines create compact, easy-to-use packaging for convenience and portion control.

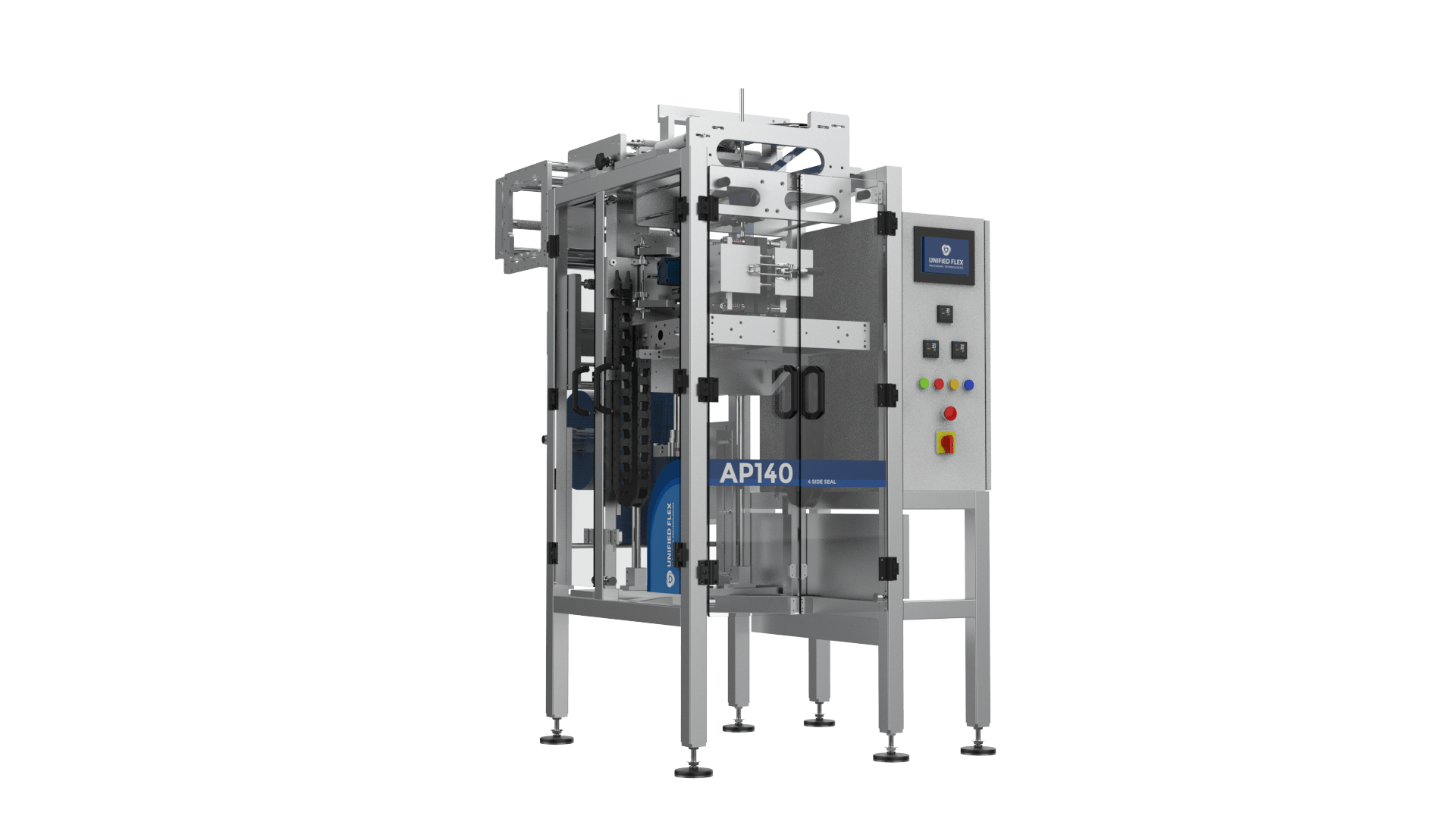

2. Sachet Machines

Sachet machines package small portions of gels and liquids in 3 Side Seal or 4 Side Seal pouches. This format is commonly used for shampoos, lotions, hand sanitizers, and condiments, offering a lightweight and cost-effective solution.

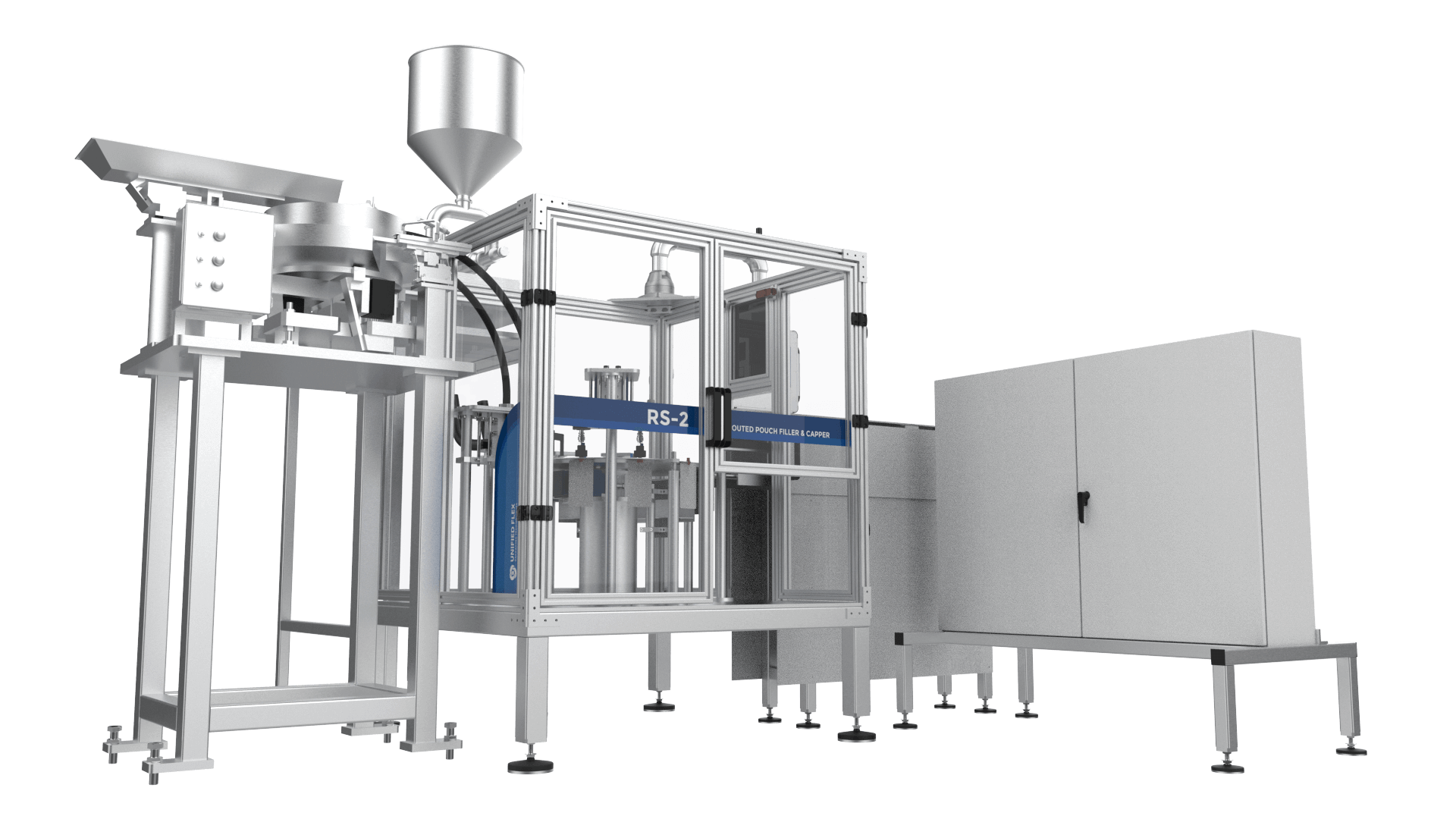

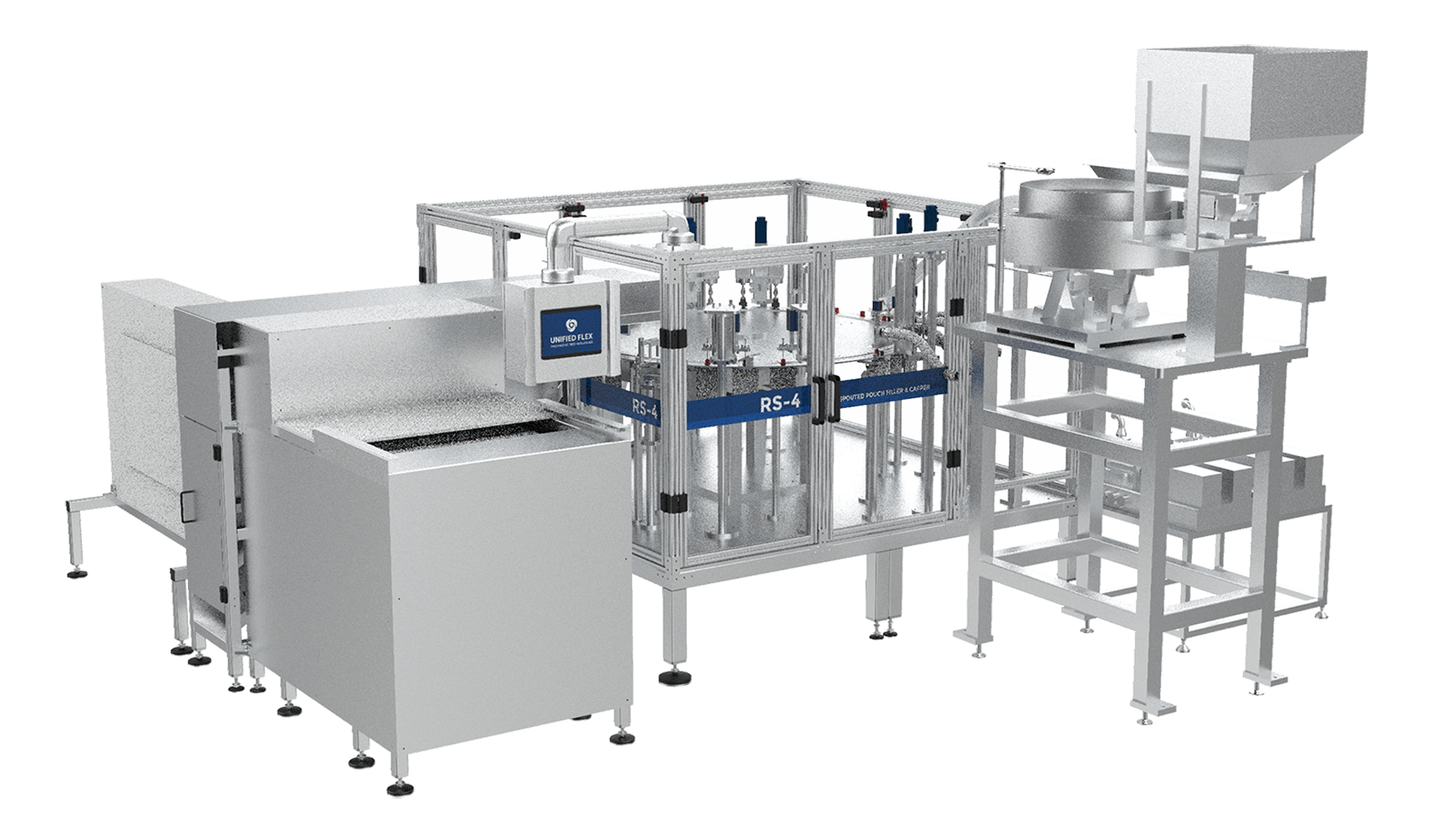

3. Spouted Pouch Filling & Capping Machines

Spouted pouch machines fill and cap preformed pouches with spouts, ensuring easy dispensing and resealability. These are ideal for juices, dressings, personal care products, and household liquids.

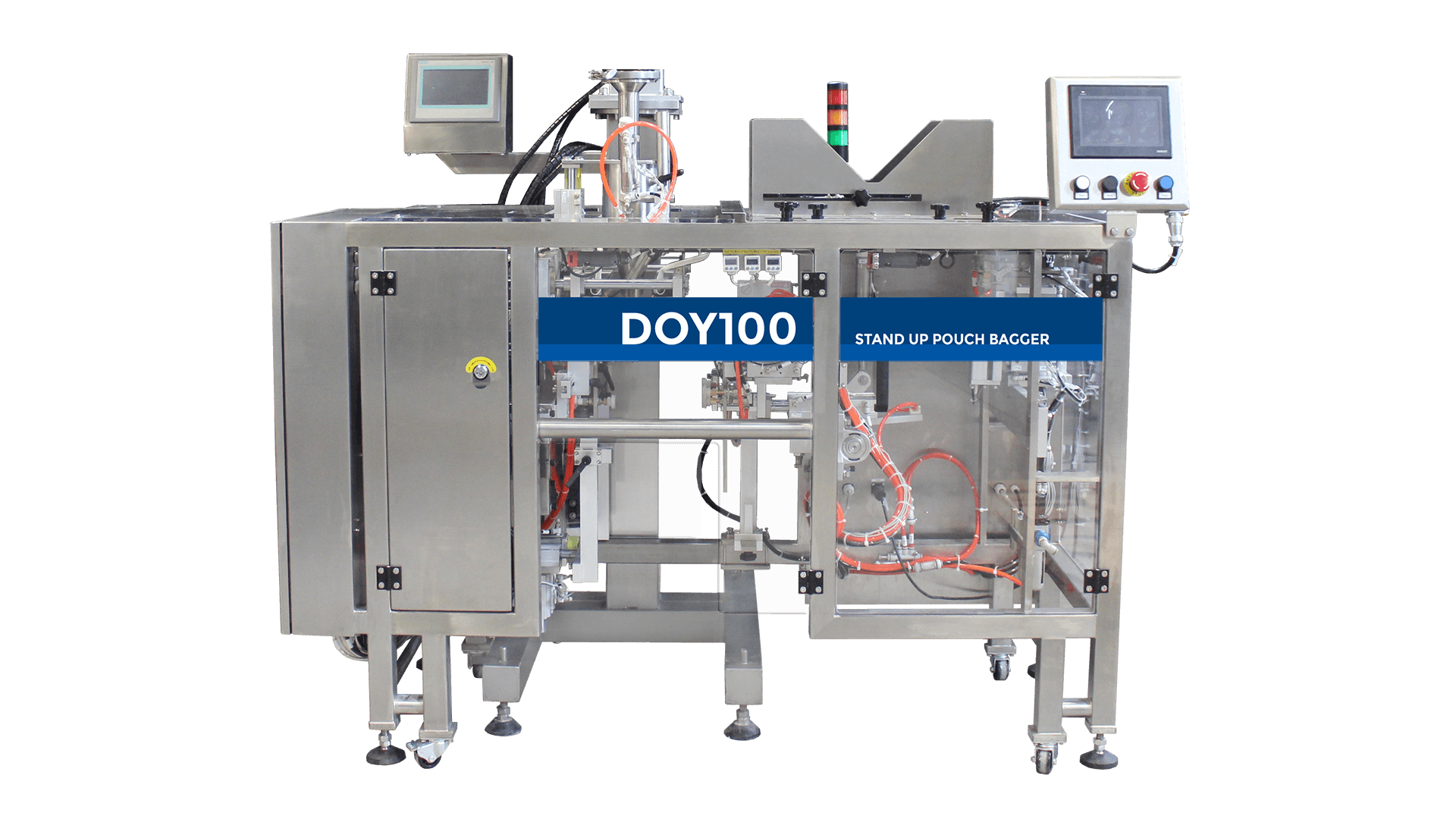

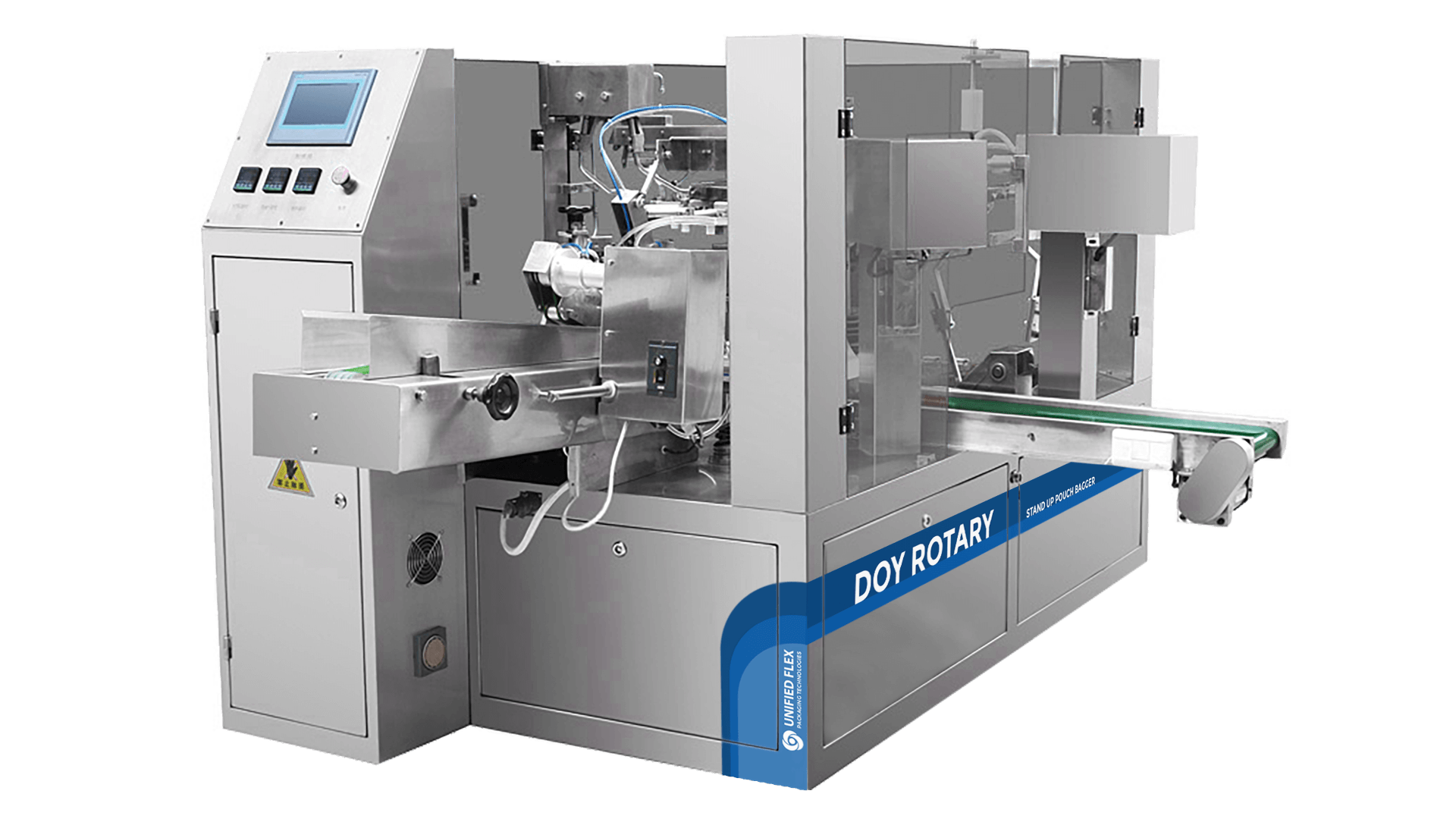

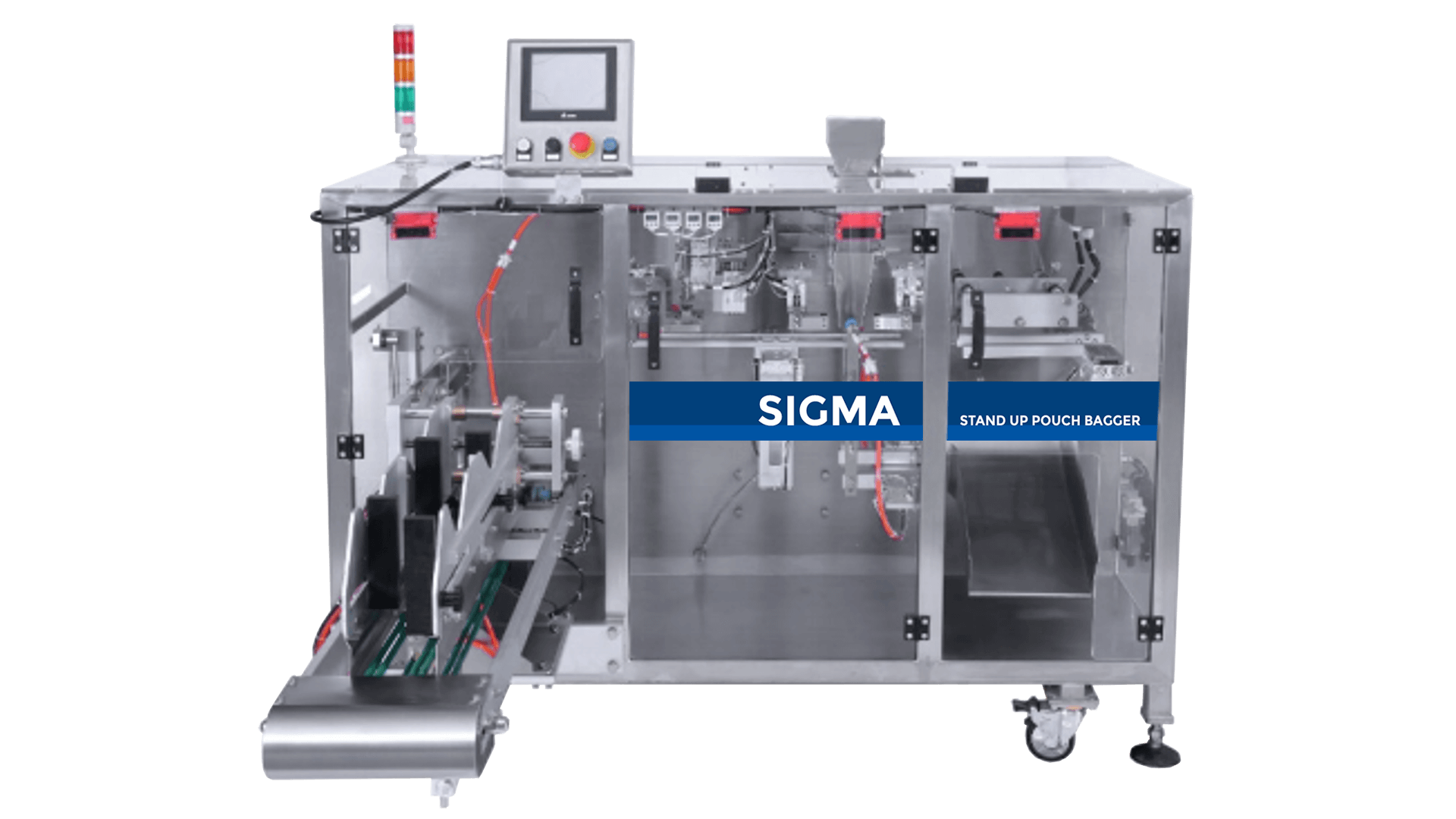

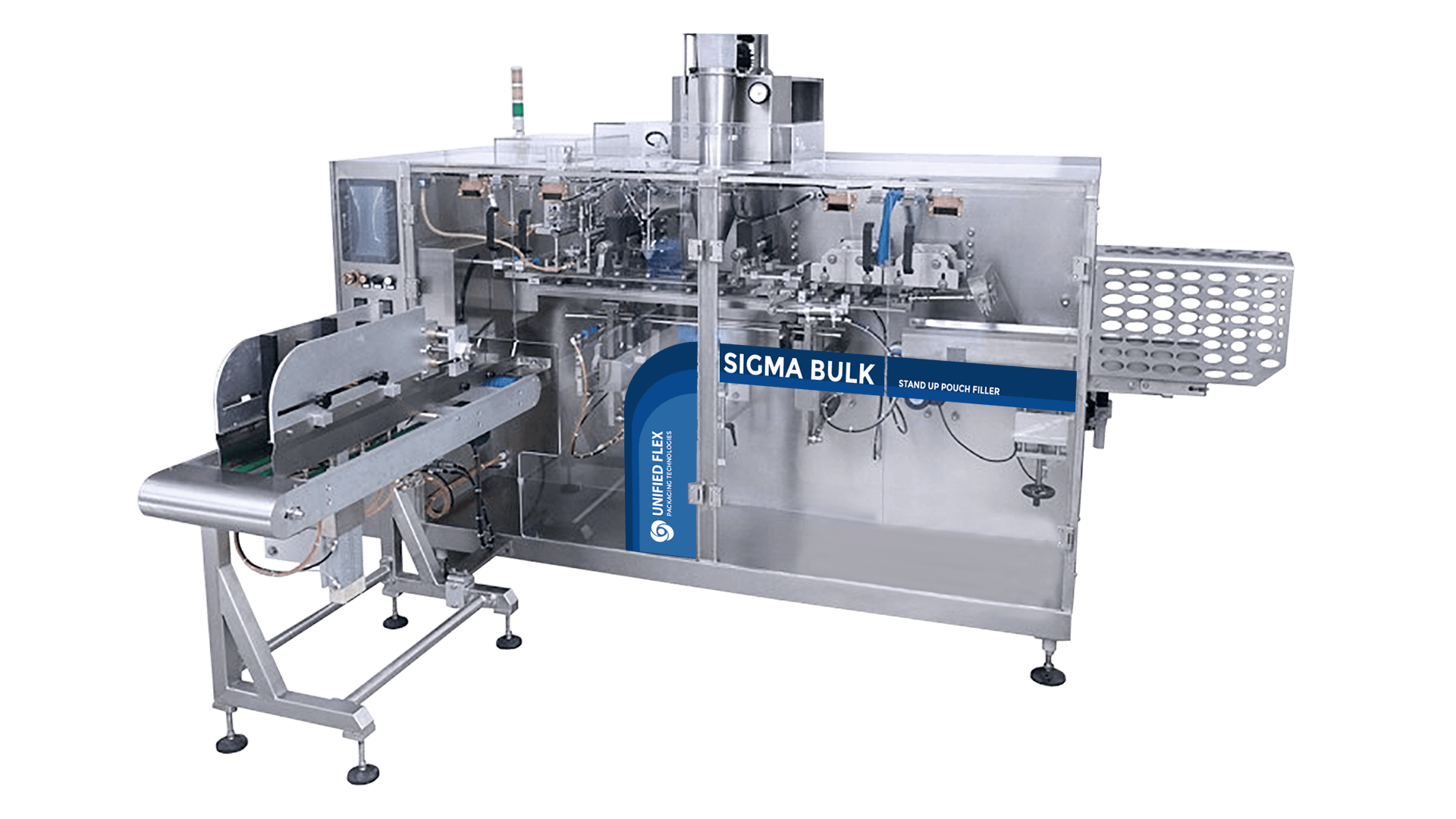

4. Stand-Up Pouch Bagging Machines

Designed for preformed pouches, these machines handle spouted pouches, flat-bottom pouches, and box pouches. They offer versatile packaging for food, beverages, and personal care products.

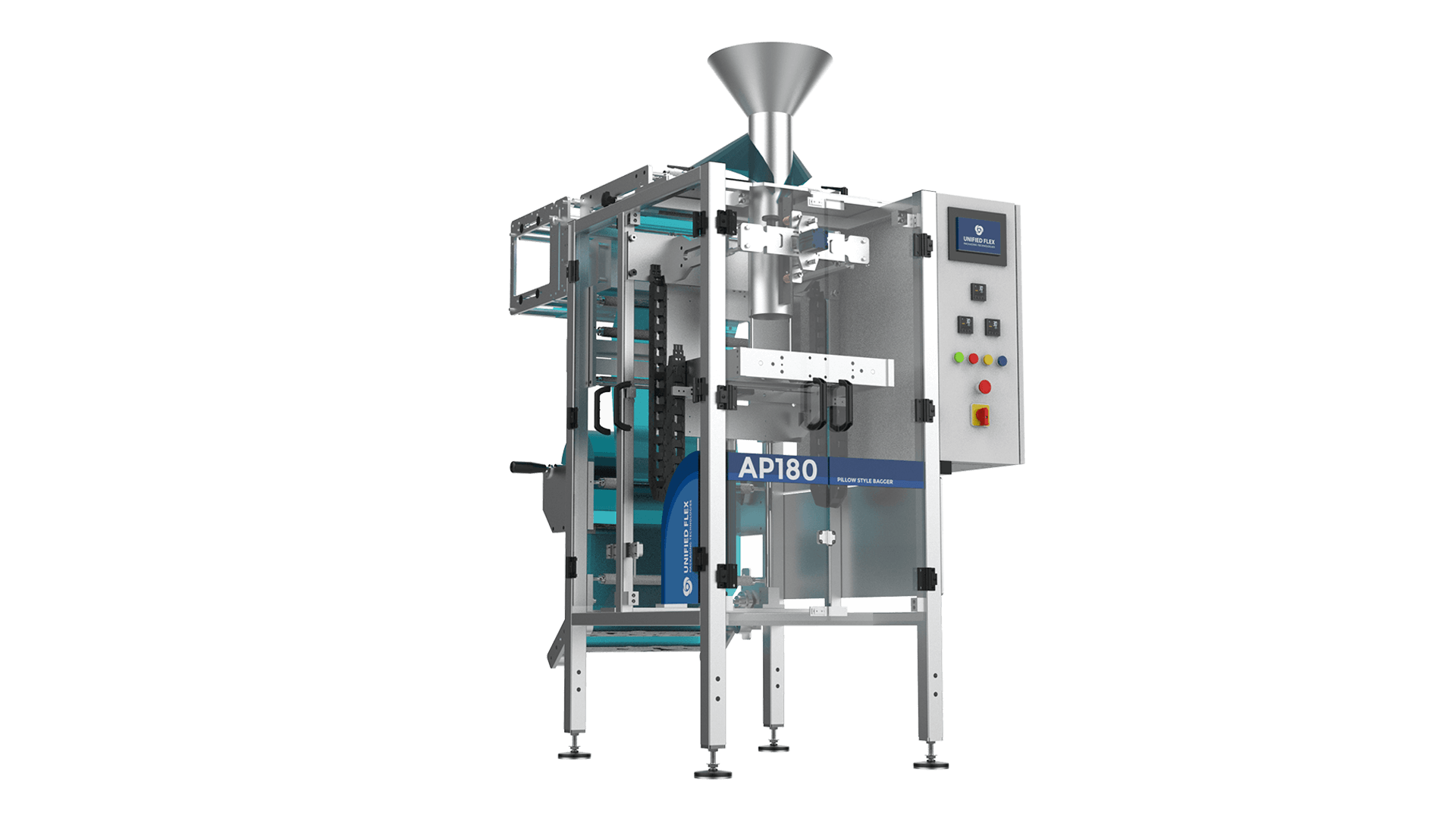

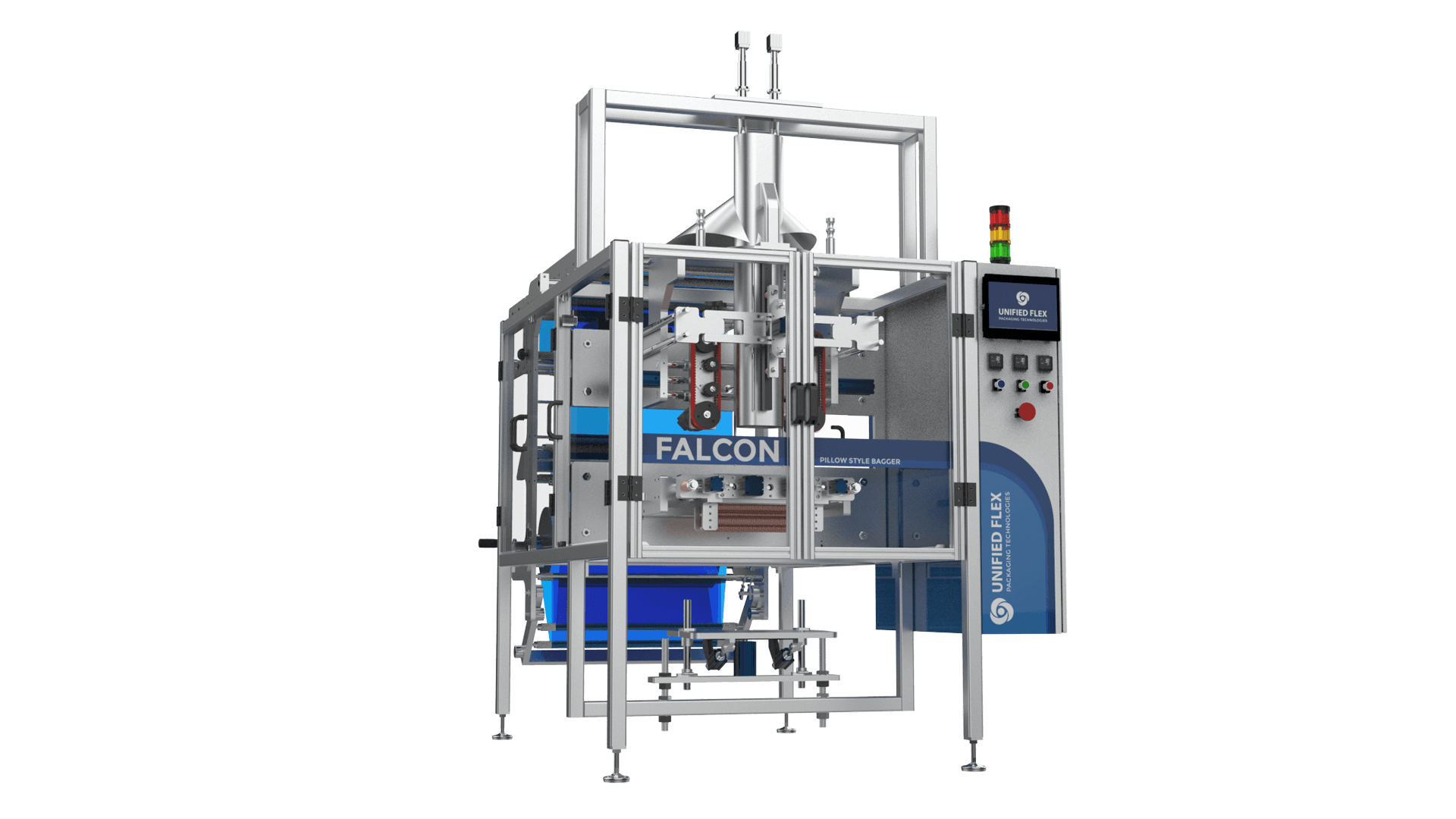

5. Vertical Form Fill Seal (VFFS) Machines

VFFS machines create pillow bags, gusseted bags, and block-bottom pouches for high-speed liquid packaging. They are used for products like sauces, cleaning solutions, and soups, with options for ultrasonic sealing to prevent leaks.

6. Popsicle Packaging Machines

Popsicle packaging machines are designed for efficient, high-speed packaging of liquid and semi-liquid frozen treats. These machines ensure consistent portioning and airtight sealing to maintain product integrity.

Each of these machines is designed to meet different product and production requirements, ensuring secure and efficient packaging for gels and liquids.