Inside the Modern Commercial Packaging Machine: Building Real Consistency in Bulk Food Packaging

Why Bulk Packaging Is a Different Engineering Challenge

Bulk food packaging looks simple from the outside: fill a bag, seal it, and stack it. But on the production floor, the physics tell a different story. Grains settle unevenly. Beans rebound as they drop. Powdered products cling to everything. Sealing jaws pick up dust. Films expand, contract, and sometimes drift under tension. When each of these behaviors happens at industrial speeds, even small inconsistencies can lead to downtime, waste, or leaks that show up only after shipping.

This is where engineering matters more than marketing. A modern commercial packaging machine doesn’t just form and fill bags; it manages motion, tension, and temperature in a controlled relationship. The goal isn’t only to seal faster but to seal better, to make every weld, every cut, and every drop motion repeatable under changing conditions. For bulk operations, there is a difference between a smooth day and an expensive one.

The Real-World Pressures in Bulk Food Packaging

1. Product Flow Variability

Each bulk ingredient behaves differently under gravity and vibration. Rice flows freely; beans bounce and roll; powders bridge and release in bursts. If dosing speed, sealing motion, and film pull aren’t synchronized, the result is uneven fills, trapped air, and poor seal cleanliness.

2. Seal Reliability Under Load

A five-kilogram bag looks sturdy until it’s stacked on a pallet. Seal integrity determines whether that bag stays intact or bursts under compression. Small inconsistencies in temperature, dwell time, or pressure lead to weak seams, especially when product dust contaminates the seal zone.

3. Film Tracking and Alignment Drift

In bulk packaging, small mechanical drifts multiply. A one-millimeter film offset at the forming collar can produce crooked back-seals and misaligned print across an entire run. With printed film, even minor drift wastes expensive material.

4. Changeovers and SKU Variability

Modern bulk operations must run multiple bag sizes and products on the same line. But frequent changeovers introduce risk, tension, sealing temperature, and timing must all be recalibrated. Without modular design and recipe storage, every adjustment is an opportunity for error.

5. Sustainability and Downgauged Films

As sustainability goals push toward thinner, recyclable films, the sealing window gets narrower. Downgauged structures are more sensitive to temperature fluctuation and stress at the seams. What used to be a forgiving process now requires precision control of heat, tension, and pressure.

Bulk food packaging is a test of balance: between speed and seal quality, between flexibility and consistency, between performance and sustainability.

Solutions That Redefine Consistency

A. Controlled Product Flow and Dosing Accuracy

A reliable seal begins long before the jaws close. When film draw, product dosing, and sealing motion operate in sync, the product settles evenly and the seal zone stays clean. Servo-controlled pulling belts and servo-driven horizontal jaws maintain consistent film movement and timing — the same architecture used in Unified Flex’s production-grade systems.

For powders, vacuum-assisted settling or gentle agitation helps maintain fill accuracy and prevent dust from entering the seal area. For beans or rice, a lift-and-settle profile minimizes bounce and trapped air. The result is uniform weight, consistent seals, and smoother product flow through every cycle.

B. Web Stability and Seal Integrity

Film control defines both the appearance and reliability of every package. A stable web ensures that printed graphics align correctly, seals form evenly, and each bag maintains its intended geometry. Closed-loop film tension and self-aligning pulling belts work together to keep the film centered and steady as it moves through the forming and sealing stages. A print-mark photo sensor continuously checks alignment, ensuring every cut and back-seal remains accurate throughout production.

Temperature consistency is equally critical. Digital temperature controls monitor not only the heater bands but also the sealing jaw surface, maintaining even thermal energy through every cycle. This balance of heat and pressure—delivered through precise servo-driven motion—creates smooth, uniform seals that resist compression, vibration, and long-term storage stress. Even under heavy fill weights, the film tracks straight, seals cleanly, and protects package integrity through transport and distribution.

C. Modular Design and Quick-Change Flexibility

Modern bulk lines must handle different bag sizes and formats without downtime. Tool-less forming-collar assemblies and quick-release components allow changeovers in minutes. Each time an operator recalls a stored recipe, parameters for temperature, dwell, and tension reset automatically to validated values.

This modular design goes beyond convenience; it preserves accuracy. A self-aligning forming collar and convenient back-seal alignment ensure that the first bag after a changeover performs exactly like the last one before it. Consistency stays locked in, even as SKUs change.

D. Process Efficiency and Energy Control

A high-speed packaging and filling machine delivers real value only when it runs efficiently. Servo-driven motion across sealing and pulling assemblies minimizes energy loss while maintaining steady performance. Digital temperature regulation prevents heat drift and reduces component wear.

This design enables downgauged or recyclable films to seal reliably in continuous operation. Controlled heat zones, reduced heat soak, and efficient servo operation lower total energy use, supporting sustainability targets without compromising throughput or seal quality.

E. Validation and Repeatability

Consistency is engineered through verification. Machines that record seal temperature, dwell, web tension, and cut length allow operators to re-establish proven process windows at any time. Unified Flex systems, built around Omron PLC control with an HMI touch panel, let operators view and adjust every critical parameter in real time.

This level of validation turns experience into data. When parameters are saved and recalled, the process behaves the same way across shifts, operators, and production runs, reducing waste, stabilizing output, and ensuring every bag meets the same measurable quality standard.

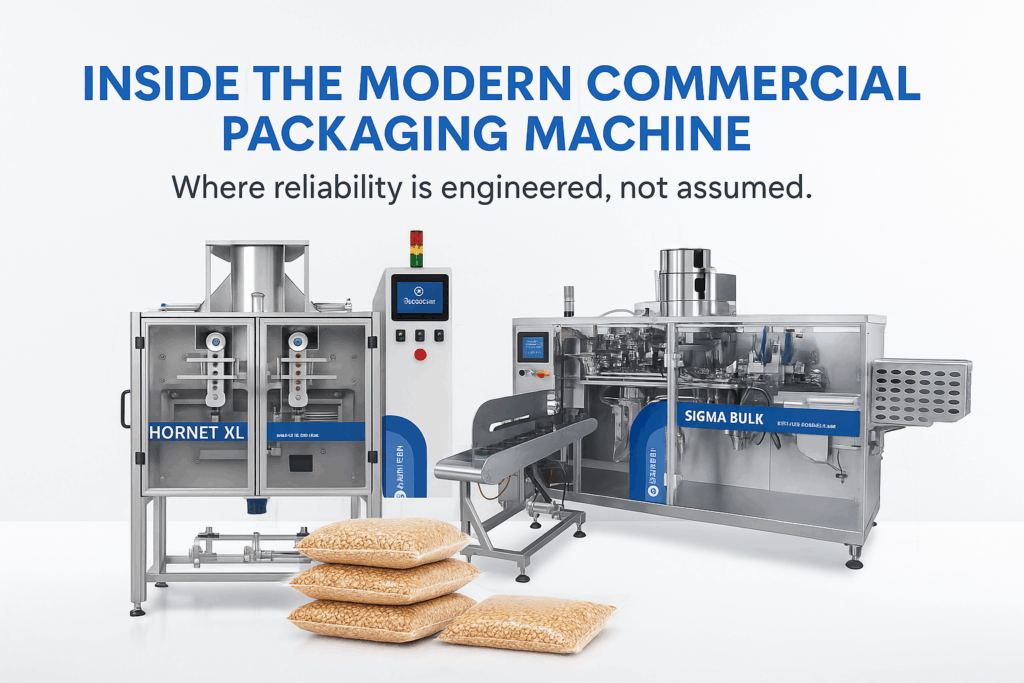

Two Paths to the Same Reliability Philosophy

Not every plant runs the same format, but the engineering logic should always align. Unified Flex applies the same mechanical DNA, servo precision, modular construction, and controlled sealing across two core automation paths.

Vertical Form Fill Seal (VFFS) for rollstock applications:

The VFFS Vertobagger Hornet XL exemplifies this approach. Designed for large pillow or side-gusseted bags, it forms, fills, and seals in one continuous motion. Its servo-driven draw belts maintain exact film tension, while thermal control ensures seals form cleanly even under heavy fill weights. It’s the reliable workhorse for high-volume producers running pillow or gusseted bags efficiently from film rollstock.

Stand-Up Pouch Bagging Machines for large-format pouches:

The DOY Sigma Bulk takes a different route. Each pouch is positively opened, filled, and sealed across discrete stations. That design minimizes product contamination, protects geometry, and maintains seal quality under load, ideal for bulk retail or institutional formats that demand both strength and presentation.

Both systems aim for the same outcome: reliable, repeatable bulk food packaging. The difference lies in scale and handling, VFFS for efficiency and film economy, and preformed pouch systems for precision under weight.

What “Good” Looks Like in Bulk Food Packaging

When film handling, sealing, and product flow are synchronized, the improvements are immediate, and measurable:

- Lower film waste through accurate registration and optimized cut length.

- Stronger seals that withstand compression and drop impact.

- Shorter changeovers that maintain target parameters without re-tuning.

- Reduced downtime from fewer seal failures and cleaner runs.

- Better sustainability performance with thinner, recyclable films and lower energy use.

- Predictable throughput that stabilizes downstream case packing and palletizing.

These aren’t theoretical benefits. They’re the practical metrics packaging engineers track every day: yield, uptime, and integrity per shift.

Conclusion — The Measurable Side of Reliability

In bulk packaging, reliability isn’t about speed, it’s about repeatability. When a seal holds, when film tracks straight, when weights stay consistent from the first bag to the thousandth, that’s the result of controlled motion, thermal precision, and validated parameters.

A well-engineered commercial packaging machine turns variability into predictability. Whether that’s a VFFS unit forming bags from rollstock or a preformed pouch packaging and filling machine managing heavy pouches, the goal is identical: to keep packaging strong, efficient, and repeatable, every shift, every batch, every day.