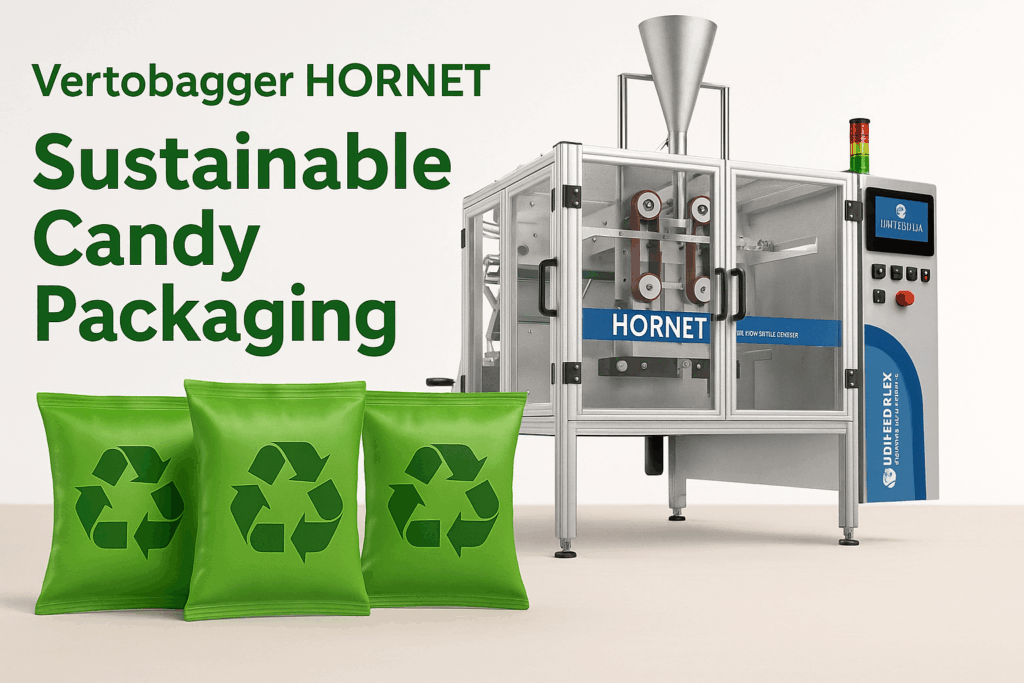

Sustainable Candy Packaging: How the Vertobagger Hornet Helps Brands Go Green

The candy aisle is more colorful than ever, not just from the products themselves, but from the vibrant packaging designed to capture consumer attention. Yet behind that bright exterior, the candy industry faces a serious challenge: sustainability.

Consumers today don’t just care about what’s inside the bag. They want to know that the packaging holding their favorite sweets is eco-friendly, responsibly sourced, and easy to recycle. According to Shorr Packaging, nearly 54% of consumers actively seek out products with sustainable packaging, making it a key factor in purchasing decisions.

For candy manufacturers, this represents both an opportunity and a challenge. Creating packaging that protects delicate confections, meets retailer standards, and aligns with environmental goals requires innovation at every stage of production, especially when it comes to the machines that bring packaging to life.

This is where sustainable candy packaging begins: with the right strategy, the right materials, and the right equipment.

Why Sustainability Can’t Wait

For years, sustainability was seen as a nice-to-have feature for brands looking to appeal to niche audiences. Today, it’s a baseline expectation. Governments across North America are implementing stricter regulations on single-use plastics and waste reduction. Major retailers are setting aggressive sustainability targets, requiring suppliers to use recyclable or compostable packaging films.

In the candy industry, this shift is even more pressing. Candy products are often packaged in single-use flexible films, and the sheer volume of seasonal products, think Halloween or Valentine’s Day, creates huge spikes in packaging waste. If manufacturers don’t adapt, they risk losing shelf space, market share, and consumer trust.

The Challenges of Sustainable Candy Packaging

Creating sustainable candy packaging isn’t as simple as swapping one material for another. Flexible packaging must still meet a variety of requirements:

- Product Protection: Candy is highly sensitive to moisture, temperature, and oxygen exposure. Any eco-friendly material must provide the same barrier properties as traditional films.

- Aesthetic Appeal: Packaging must remain visually appealing to stand out in crowded aisles, especially for impulse-buy products.

- Production Efficiency: New materials often behave differently during sealing and forming, requiring precise, adaptable equipment.

- Cost Management: Sustainable materials can be more expensive, making efficiency critical to maintain profitability.

This is why many candy producers are taking a holistic approach, focusing not just on materials but on machines that can handle sustainable films with precision and care.

Sustainability Starts With Smarter Equipment

The right candy packaging machine plays a critical role in reducing environmental impact. Outdated or inefficient machines often create waste through misaligned seals, inconsistent bag lengths, and frequent rework. These issues not only increase material consumption but also drive up energy costs.

Reliable machines like the Vertobagger Hornet are designed to work seamlessly with today’s thinner, recyclable films. With servo-controlled precision and digital temperature control, the Hornet minimizes material waste while ensuring strong, airtight seals, a crucial factor for protecting product quality.

By reducing errors and streamlining production, candy manufacturers can cut both their environmental footprint and their operating costs, proving that sustainability and profitability can go hand in hand.

Meeting Seasonal Spikes Without Compromise

Seasonal candy production creates some of the industry’s highest volumes and its biggest sustainability hurdles. In the weeks leading up to Halloween or Easter, production lines run nonstop, generating massive amounts of packaging material.

The Vertobagger Hornet helps mitigate this challenge with speeds of up to 80 bags per minute, giving manufacturers the ability to meet demand without sacrificing accuracy. Faster, more consistent output means less wasted film, fewer rejected bags, and a smoother supply chain overall.

For brands aiming to make their seasonal promotions greener, the Hornet provides the scalability needed to balance efficiency and environmental responsibility.

Flexibility for Sustainable Innovation

As consumer trends evolve, so do packaging requirements. Many candy brands are experimenting with new package formats designed to reduce waste while maintaining shelf appeal.

The Vertobagger Hornet offers the versatility to handle multiple sustainable packaging styles, including:

- Pillow bags for everyday, cost-effective packaging.

- Side-gusseted bags for premium, bulk, or resealable products.

- Pillow bags with eurohole for efficient hanging displays.

With tool-less forming collar assembly changeovers, switching between these formats is fast and simple. This allows candy manufacturers to introduce new sustainable designs or seasonal offerings without long periods of downtime. Such flexibility is essential to staying ahead of shifting consumer expectations and retailer demands.

Sustainability Beyond Materials

While recyclable and compostable films are important, sustainable candy packaging also involves reducing waste at every stage of production.

The Hornet supports this with features like:

- Nitrogen flushing to extend shelf life, reducing product spoilage.

- 360-degree machine access for faster maintenance and reduced downtime.

- Quick belt changeovers to keep production running efficiently during the peak period.

These operational efficiencies translate to lower energy consumption and less resource waste, important metrics for companies reporting on sustainability initiatives.

Building Consumer Trust Through Packaging

Today’s shoppers are highly informed. When they see a candy brand using eco-friendly packaging, it sends a powerful message about the company’s values. Sustainable packaging can strengthen customer loyalty, boost brand reputation, and even create premium positioning opportunities.

By investing in equipment like the Vertobagger Hornet, candy manufacturers gain the ability to deliver packaging that is not only greener but also consistent and professional. That consistency builds trust with consumers and retailers alike, laying the groundwork for long-term growth.

The Sweet Future of Sustainable Candy Packaging

Sustainability isn’t a trend; it’s the future of the candy industry. Manufacturers that act now will have a competitive edge as regulations tighten and consumer expectations rise.

The Vertobagger Hornet makes it possible to align environmental responsibility with operational excellence. By combining speed, precision, and flexibility, it empowers candy producers to package smarter, waste less, and meet their sustainability goals without compromising on quality.

In the end, sustainable candy packaging is about more than reducing waste; it’s about building a future where sweet treats can be enjoyed by generations to come.

Make Your Packaging Greener

Ready to take the next step toward sustainable candy packaging? Discover how the Vertobagger Hornet can help you achieve your environmental and business goals.